Why do we choose vacuum brazed diamond grinding wheels?

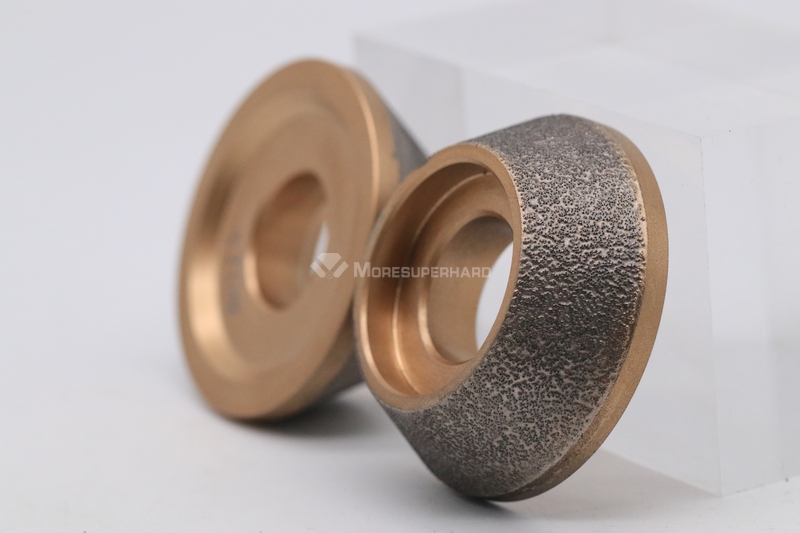

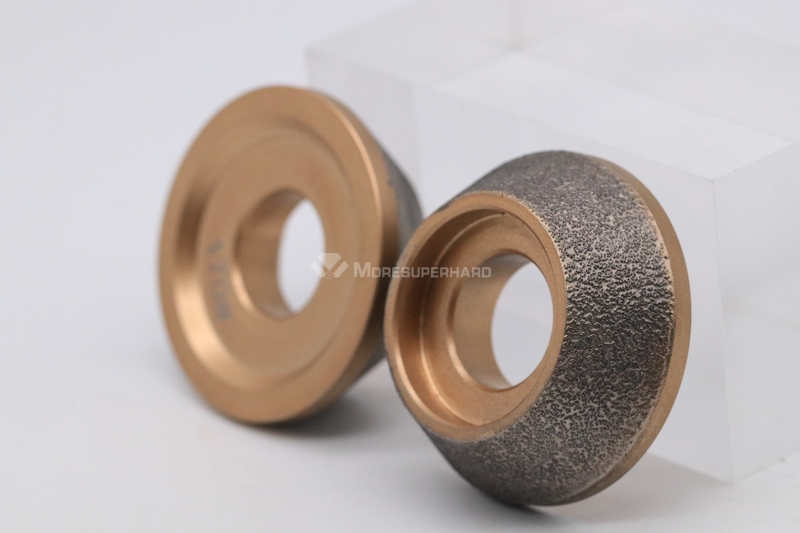

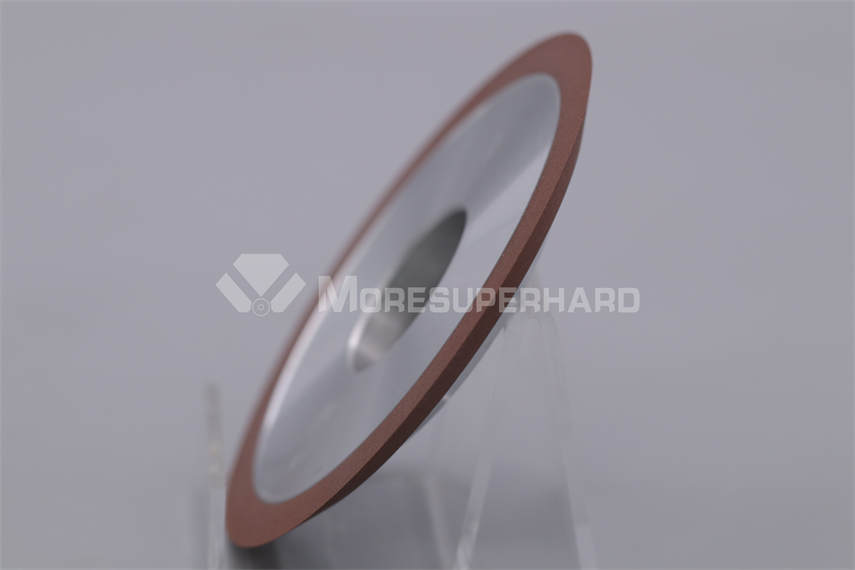

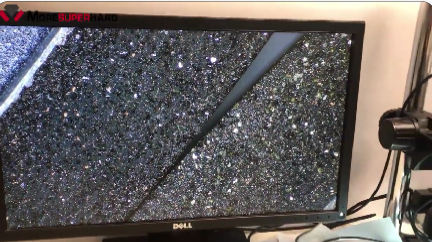

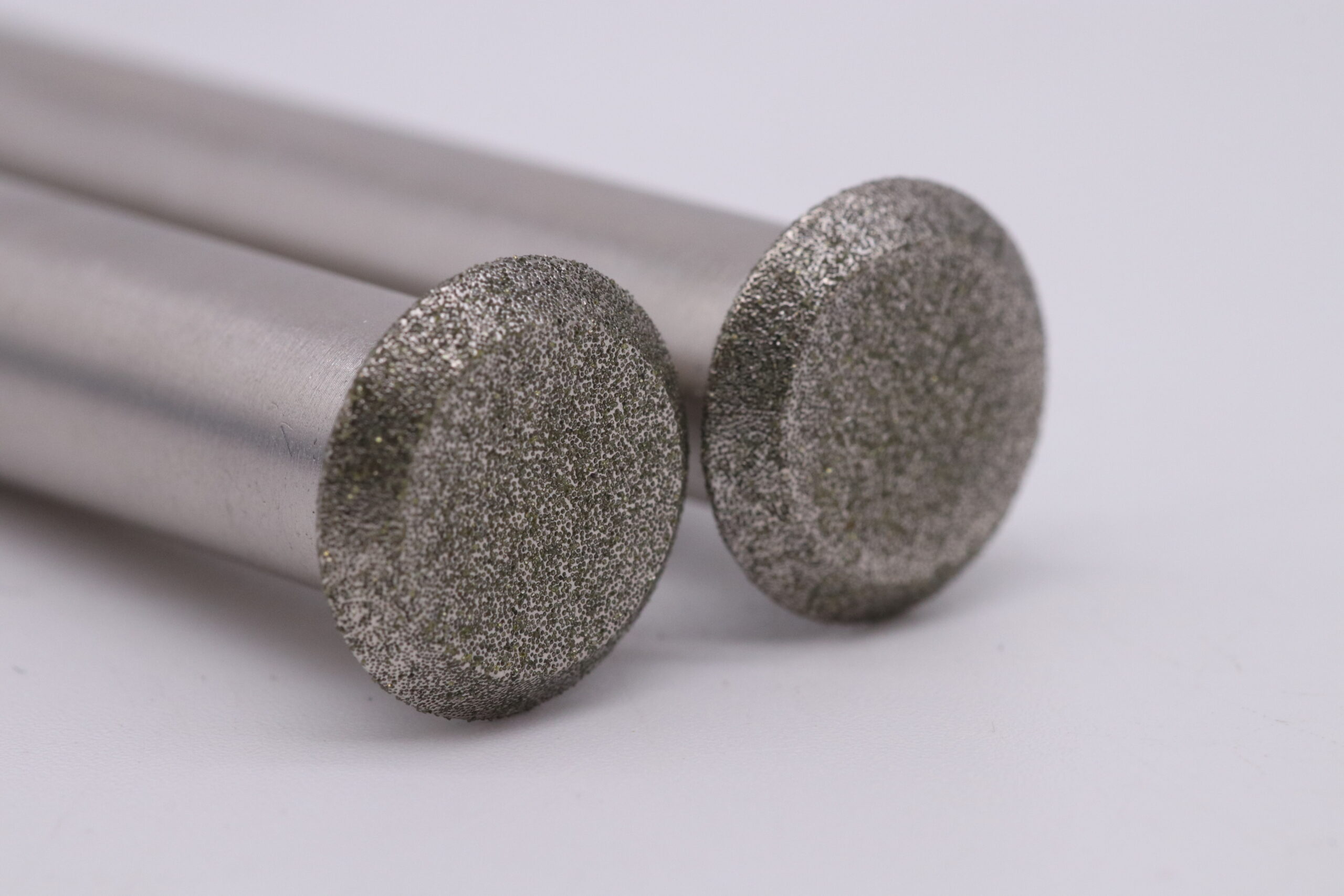

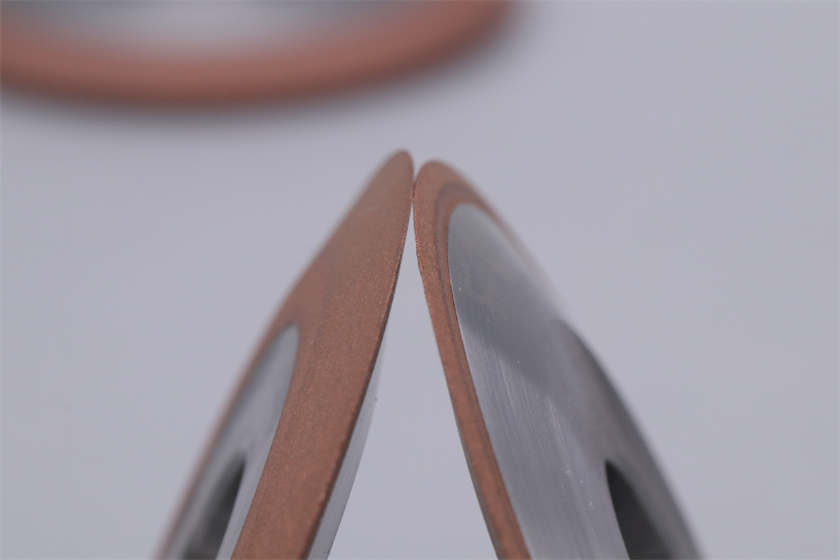

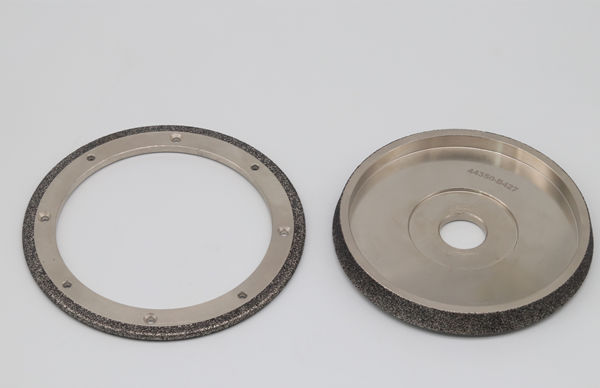

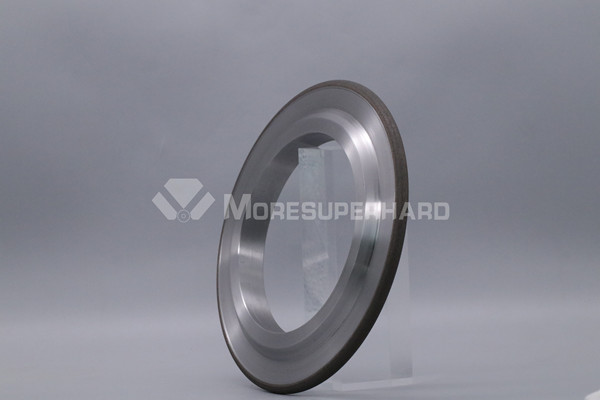

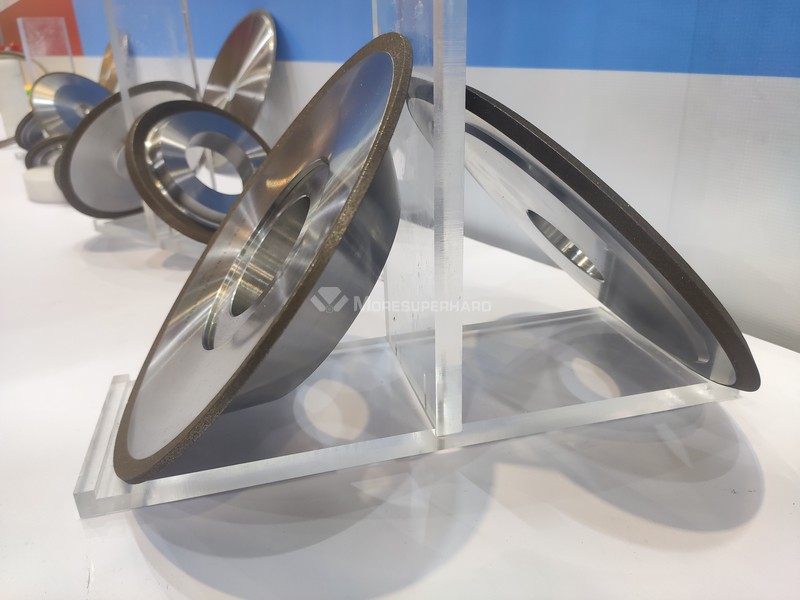

Vacuum brazing technology can realize the chemical metallurgical combination of diamond, bonding agent (brazing alloy material) and metal matrix interface, with high bonding strength. Because of the high bond strength at the interface, only a very thin bond thickness is sufficient to hold the abrasive firmly, and its exposed height can reach 70% to 80%, making fuller use of the abrasive and greatly improving the tool life and machining efficiency. Compared with the traditional technology, the maximum allowable edge value of diamond tools can be increased by more than 50%, and the diamond consumption of workpiece material per unit volume is reduced by more than half without increasing or decreasing the power consumption of tools.

Advantages of vacuum brazed diamond grinding wheel:

* high efficiency. the efficiency is improved by 30% for grinding cast steel surface, compared to conventional resin bond wheel

* long lifetime. Up to 20 times longer lifetime than Resin Bond Tools

* single layer of fully exposed diamond fused with nickel at high temperatures and sharp cutting

* never need dressing

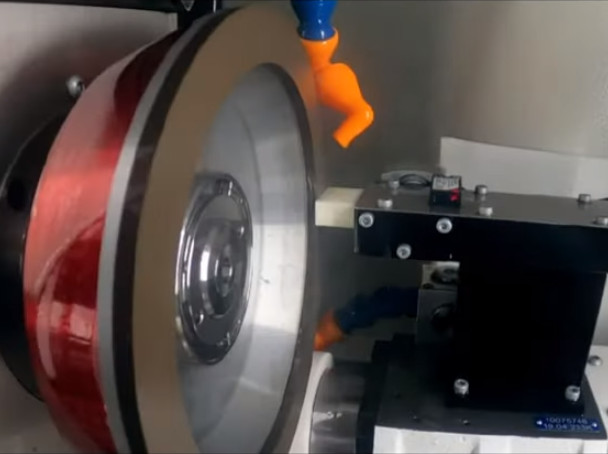

Moresuperhard’s acuum brazed diamond wheels are used on hand held grinder and used for grinding, weld cleanup, stock removal and beveling in a wide variety of industry include foundry, metal processing (weld removal and pipe beveling of all ferrous and non ferrous metals) ,auto parts, ship building , stone , ceramic, plastic processing ,and composite materials ,etc