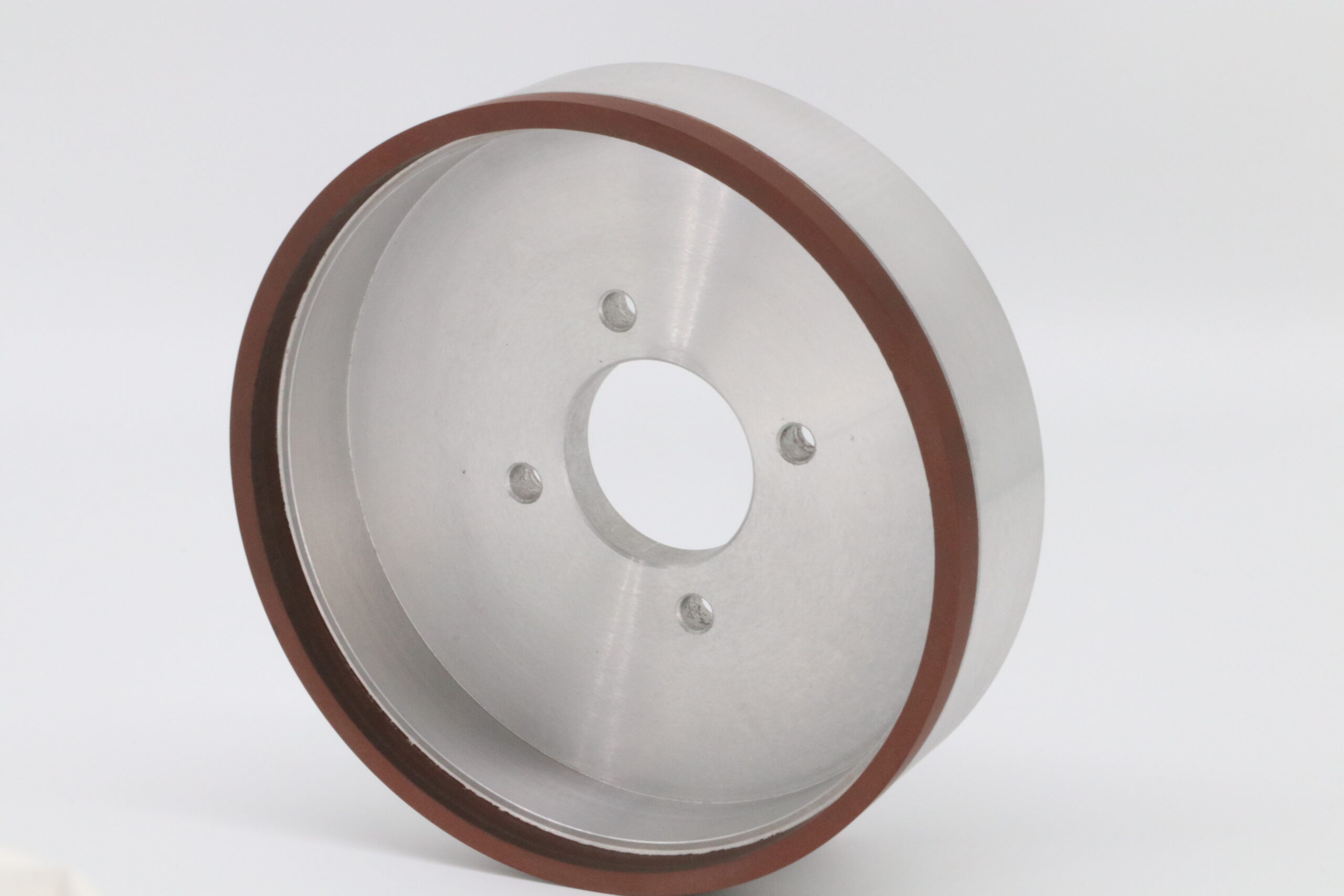

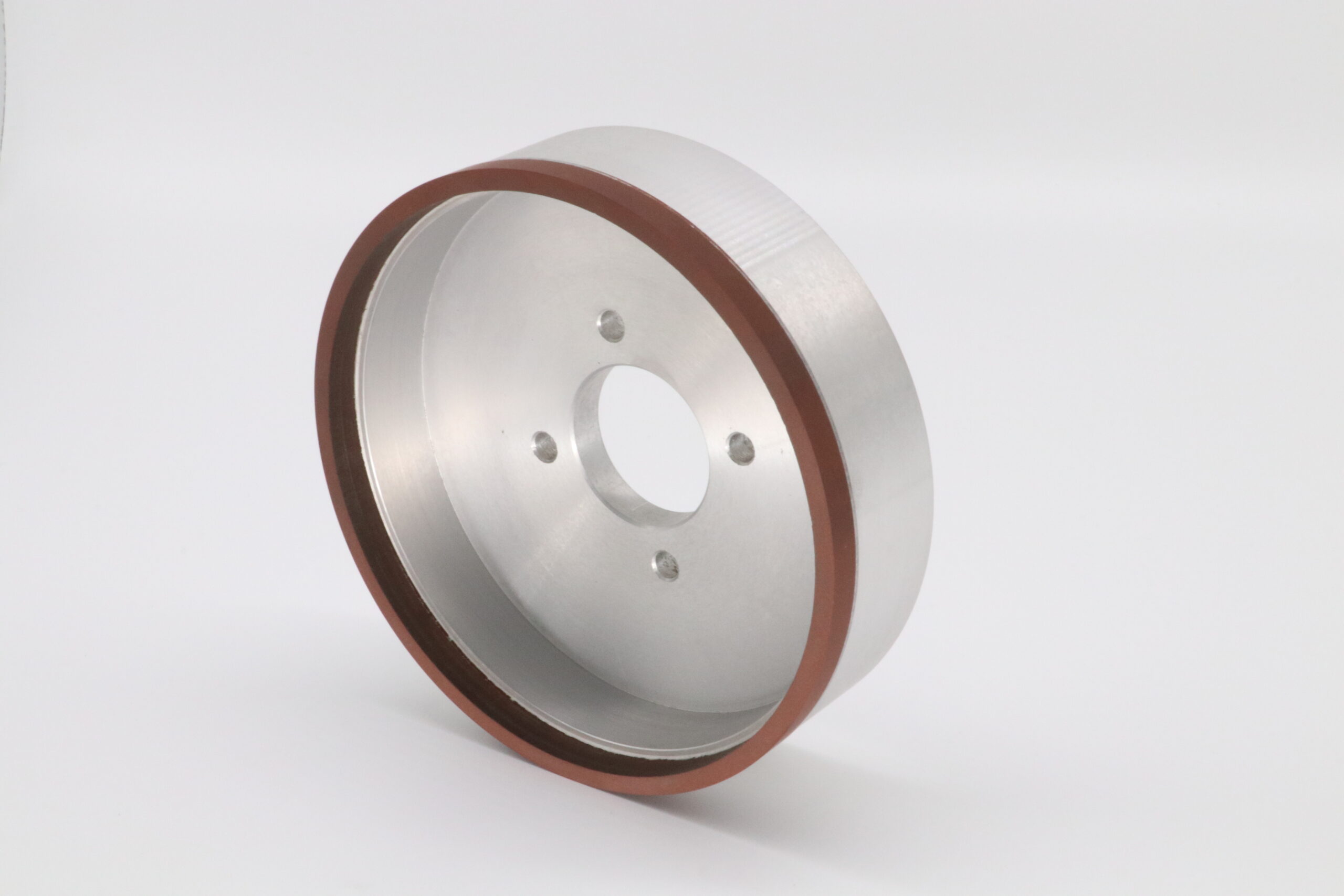

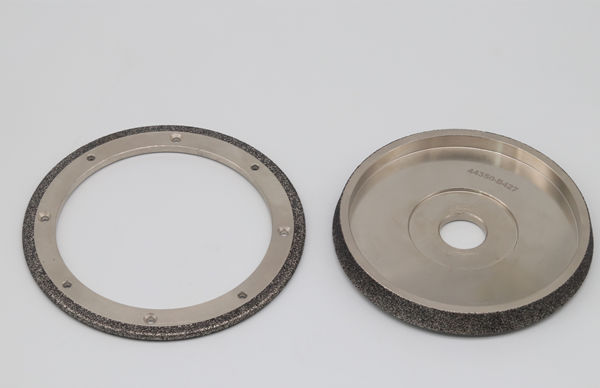

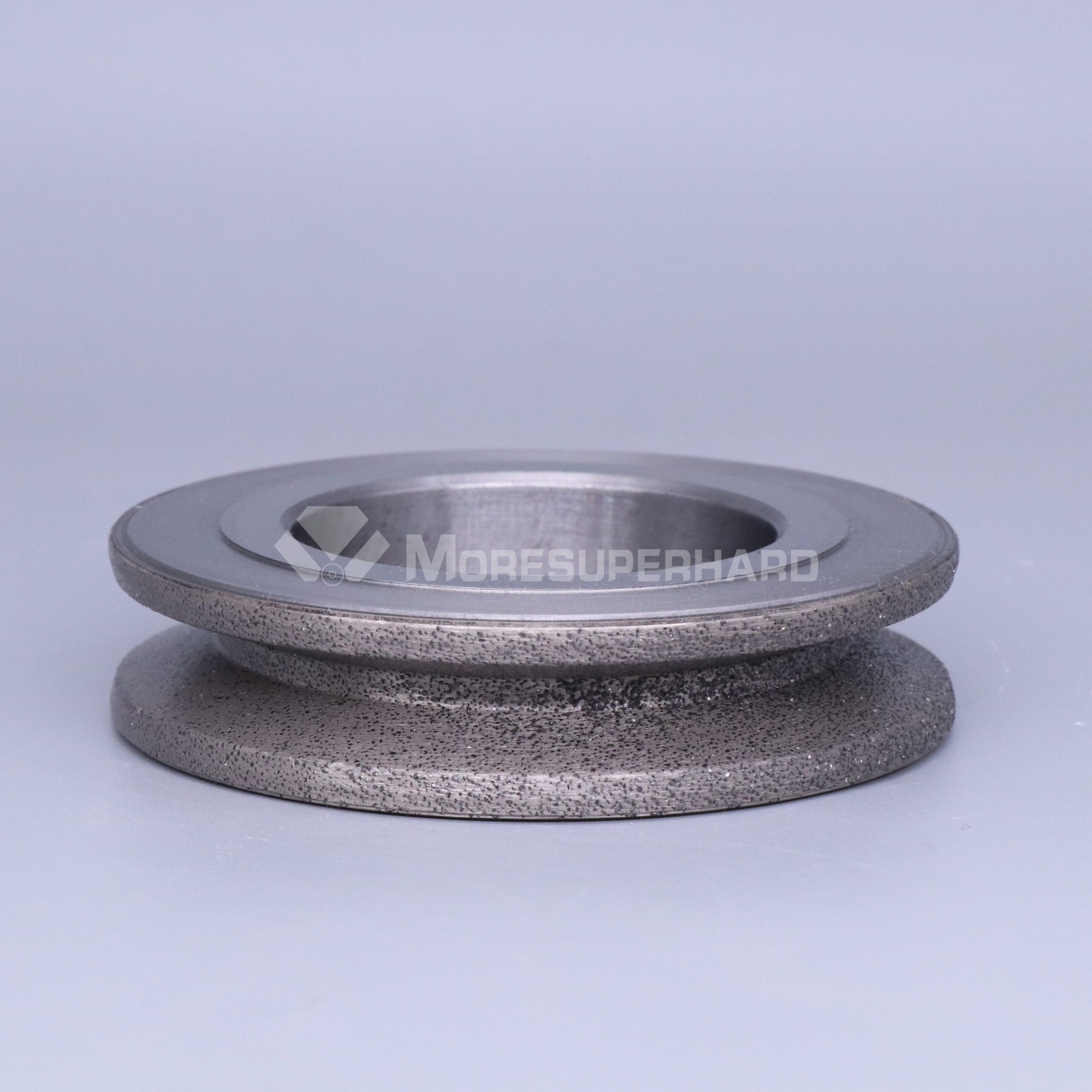

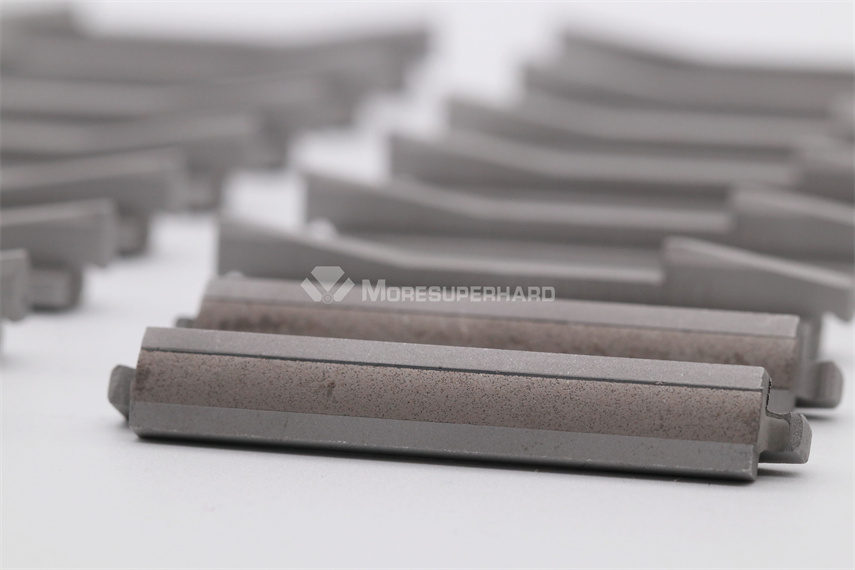

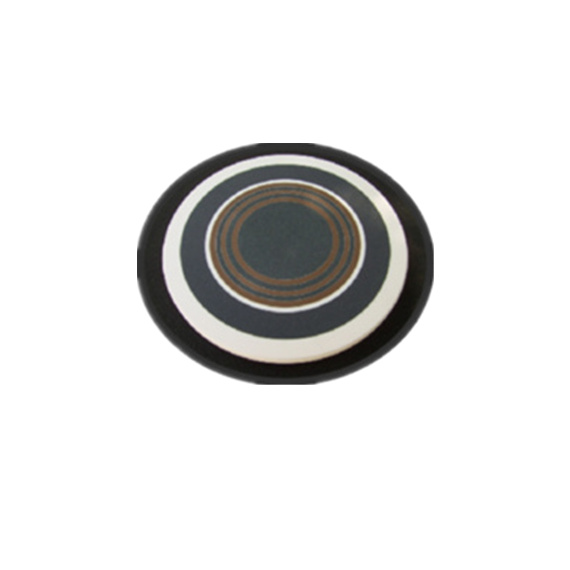

Resin Diamond Wheel for Mirror Grinding of Tungsten Carbide Tips

The diamond resin grinding wheel has a good polishing effect. The grinding wheel is sharp and not easy to be blocked during grinding.

The specific characteristics are as follows:

1. The grinding efficiency is high, and the grinding wheel consumption is relatively slow;

2. Good self-sharpening, low heat generation during grinding, not easy to block, reducing the phenomenon of work burns during grinding;

3. The grinding wheel has a certain elasticity, which is conducive to improving the roughness of the workpiece surface. It is mainly used for fine grinding, semi-fine grinding, knife grinding, polishing and other processes;

4. The diamond resin grinding wheel is cured at low temperature, the production cycle is short, and the equipment and supply process is relatively simple; due to the fluidity of the resin, it is easy to form a grinding wheel with complex surfaces

Resin grinding wheel is mainly used for grinding brittle and hard metal materials:

① high manganese steel, high carbon steel, stainless steel, die steel, bearing steel;

② high chromium, nickel, molybdenum and other heat-resistant and high-hardness alloy steel;

③ chilled cast iron (HS80 ~90);

④ All kinds of hardened steel (HRC55~65); Impellers, volutes, guard plates, sheaths, etc.), molds, cylinder liners; it solves the cutting of high-hardness and difficult-to-machine materials in all walks of life, and can improve work efficiency, greatly save processing time and electricity, and obtain huge economic benefits.