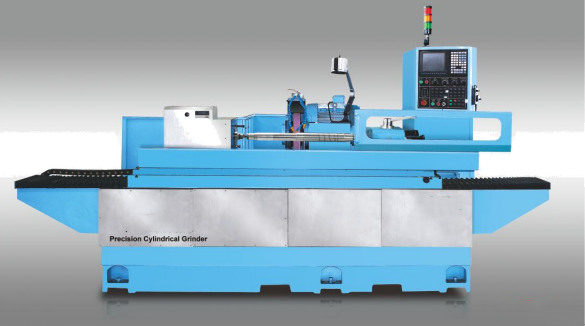

Servo Surface CNC cylindrical grinder

With hydrostatic liquid suspension electric spindle, high rigidity, high speed, low vibration, high grinding force.

►Servo Surface CNC cylindrical grinder Models

GP32

J2

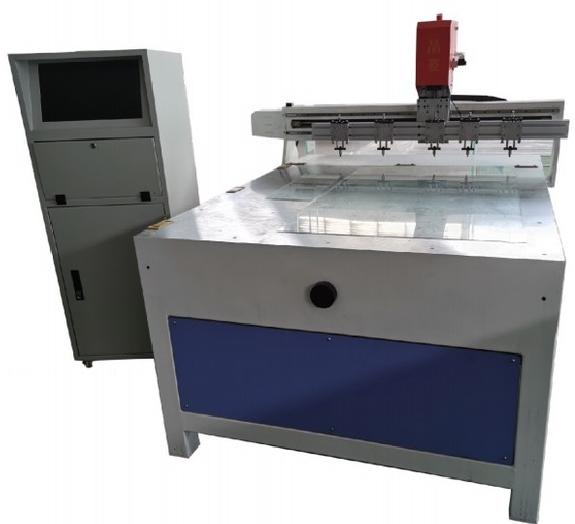

►Applications:

– automotive and aerospace industries,

– tool manufacturing

– die makingn

The processing plan adopted: (one clamping process completes grinding one after another)

a. The machine tool control system adopts Japan’s Rhenium Co., Ltd. (crankshaft special system) CNC system and digital AC servo drive. It realizes eccentric follow-up grinding through four-axis three-linkage control, and can complete multiple cylindrical contours in one clamping.

b. The machine tool is equipped with Marposs precision probe to eliminate center hole errors and achieve axial positioning and angular positioning.

c. The headstock uses a DD motor, which is controlled by a CNC system to link the headstock spindle rotation with the grinding wheel frame linear motor feed to achieve non-circular grinding profiling motion.

d. The grinding wheel frame feed is driven by an AC servo linear motor and is equipped with a grating ruler to form a closed-loop control; the feed guide rail uses a linear rolling guide rail to ensure accurate and sensitive feed.

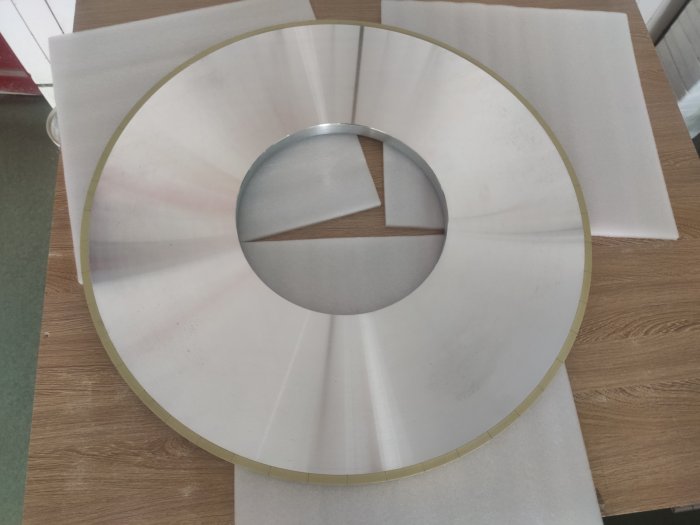

e. The machine tool grinding wheel spindle system adopts a dynamic and static pressure spindle direct-connected disc motor, equipped with a CBN grinding wheel, and grinds at a constant linear speed of 80m/s.

f. The outer diameter of the eccentric shaft is automatically ground by straight cutting. Except for manual loading and unloading, the rest of the grinding work cycle is completed automatically.

g. Use a front diamond roller to dress the grinding wheel to achieve automatic dressing and automatic compensation.

h. Overview of the grinding operation procedure: First start the dynamic pressure oil pump, hydraulic pump, and lubrication pump, dress the grinding wheel through the subroutine, and manually load the material. After the workpiece is accurately positioned, the foot switch clamps the workpiece, the door is closed manually, and the cycle button is pressed. , after the positioning is correct, the headstock rotates synchronously, the cooling pump starts the water supply, the grinding wheel frame approaches the workpiece in fast forward, and then the grinding wheel frame feeds roughly, and then fine grinds and non-sparking grinding (smooth grinding) to the size, and continues grinding and processing. outline. The grinding wheel frame quickly retreats to the original position, the head frame stops rotating, the supply of coolant stops, the protective door is opened manually, and the material is manually unloaded to complete an automatic cycle processing. When the set number of processing pieces is completed, it will automatically enter the grinding wheel dressing state, dress the grinding wheel through a subroutine, and automatically compensate.