Diamond Film Belt for Thermal Spraying Industry

Our film belt is :1. with high grinding consistency ;

2. with high grinding capacity,which can achieve precise polishing effect;

3. with high flexibility to achieve the ideal surface polishing effect;

4. Suitable for dry polishing.

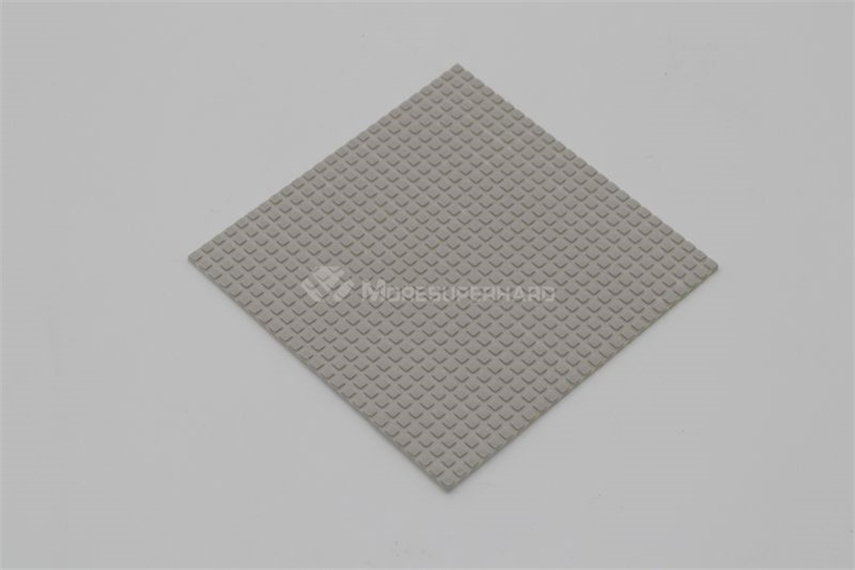

Diamond film belt , one of Ultra-precision polishing belts, is made by using advanced precision coating technology to coat the surface of high-strength films with micron, sub-micron or nano-scale abrasive micro-powders (diamond) after uniform dispersion with new polymer adhesive materials, and then processed through a high-precision cutting process.

Abrasive type: diamond (D), (customized:alumina (AO), silicon carbide (SC))

Grit size (um): 45, 30, 15, 12, 9, 6, 3, 2, 1, 0.5, 0.3

Width (mm): 1.2, 1.6, 2.0, 2.5, 3.0, 3.2, 3.8, 5.0, 12.6

Length:45m(150feet)、100m、183(600feet)、200m

*Note: In addition to the above specifications, we can customize various specification products according to customers’ needs.

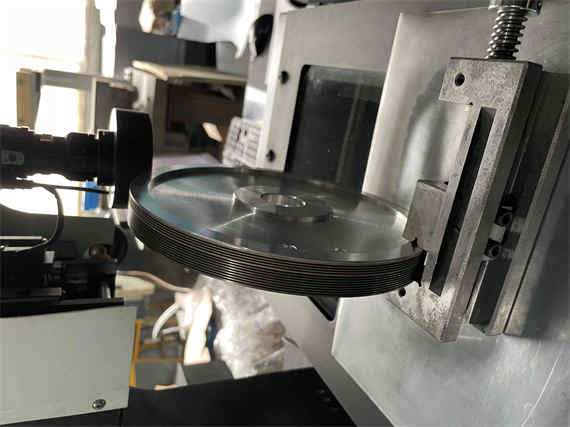

Instructions for use

1 Prohibit heavy pressure and folding of the film belt to prevent damage to the film belt grinding layer structure.

2 When installing the film belt, ensure that the equipment is tightened and fastened before turning on the machine to prevent the film belt from falling off.

3 When the polishing belt rotates the abrasive layer is very sharp, please do not touch it with your hands.