The of Optical Grinding Machine has been coated with anti-rust oil and properly packed before delivery. If you find any damages to grinder parts caused during transportation, please contact the corresponding business office as soon as possible.

The grinder has been rigorously tested and inspected. In order to give full play to the performance of the grinder, please operate by the following steps.

1 Handling and Unpacking of Optical Grinding Machine

When handling, please put the packaged unit in the place near the installation location, and then unpack.

The projector is packaged separately to prevent damage during handling. Even if tthe projector has been unpacked, it shall be installed after the main body is installed.

During handling, the lens tube of the projector may touch the body, which will affect the accuracy of the projector. Therefore, when handling the grinder in the factory, the projector must be disassembled in advance, and the grinder body must be handled separately. (When handling the projector, please remove the lens hood from the projector body first.)

The weight of the projector is 250kg. Please pay full attention to safety when handling.

2 Handling of Optical Grinding Machine Body

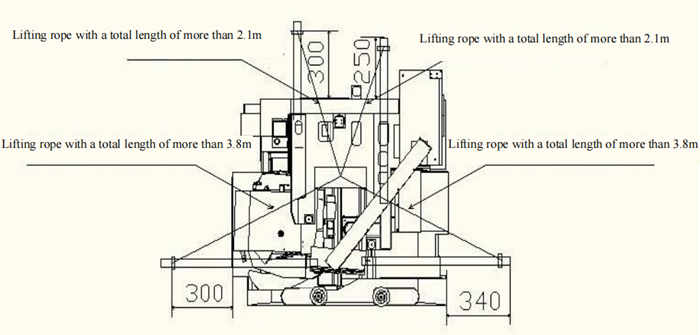

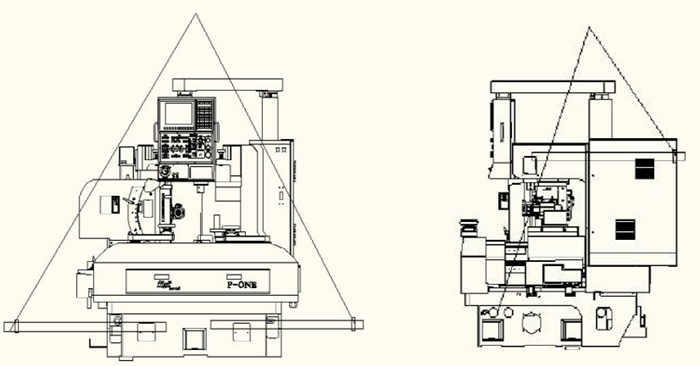

When moving the grinder, please use crane and sling with load-bearing capacity of at least 5.0t or more, as shown in Figure 2-1. (Note: The weight of the grinder body is 4.5t.)

Please hang the sling on the 2 round rods installed on the grinder body and the 2 round rods installed on the suspension wall. As for the length of the sling and the amount of the round rod protruding from the grinder body and the suspension wall, please refer to Figure 2-1

When no crane is available, please assemble the projector on the machine as close as possible to the installation site. Before moving the projector to the installation site, it is necessary to put cushion materials between the bottom of the projector and the top of the suspension wall and fix to the supporting shaft (refer to 4. assembly of the projector), so as to prevent the vibration to the projector body and prevent the projector body from falling off. After unpacking, please carefully remove the wood chips and wrapping paper. In particular, prevent the small parts contained in the package from being lost. After unpacking, please wipe off the antirust oil with a clean dry cloth, and then wipe all the processed surfaces with a cloth stained with gasoline. (Do not use paint thinner or paint cleaner in order to avoid damage to the paint on the product surface.)

In addition, optical components are vulnerable, and their accuracy may be influenced, so please pay special attention when using. Prevent the components from being impacted and place them away from high-temperature areas, etc.

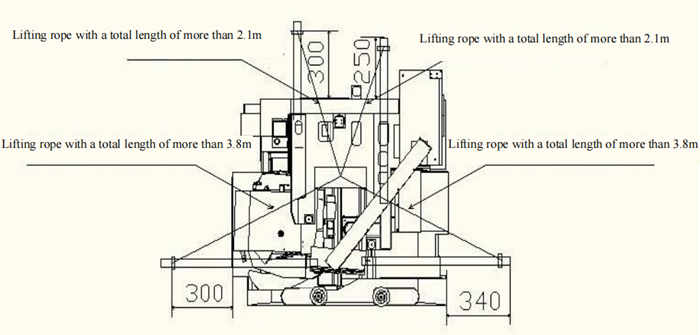

Hoisting Method of the Optical Grinding Machine Body

Pay attention to the interference of the workbench and grinding wheel table, and never let them touch the sling.

Please entrust professionals to carry out the handling and installation of grinders. Since the grinder weighs 4.5t, please use lifting rope or sling with bearing capacity of more than 20KN (capacity of single rope or sling). When hoisting the grinder, be sure to hang the rope as shown in the figure below. Please use the sling with length specified in the figure.

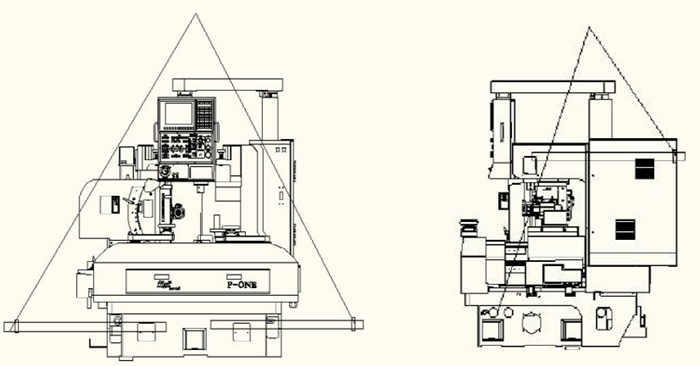

The Width Upon Delivery of Optical Grinding Machine

Upon delivery, leave an additional space of about 200mm (100mm on each side) based on the following dimensions.

Move in when the projector is installed

Note: When handling with rollers, the full height needs to be above +150 because the rollers need to be installed at the bottom of the grinder.

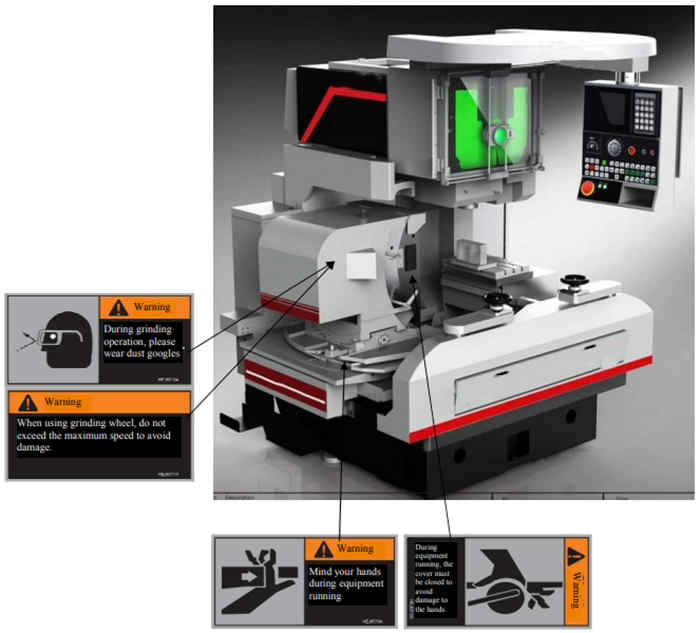

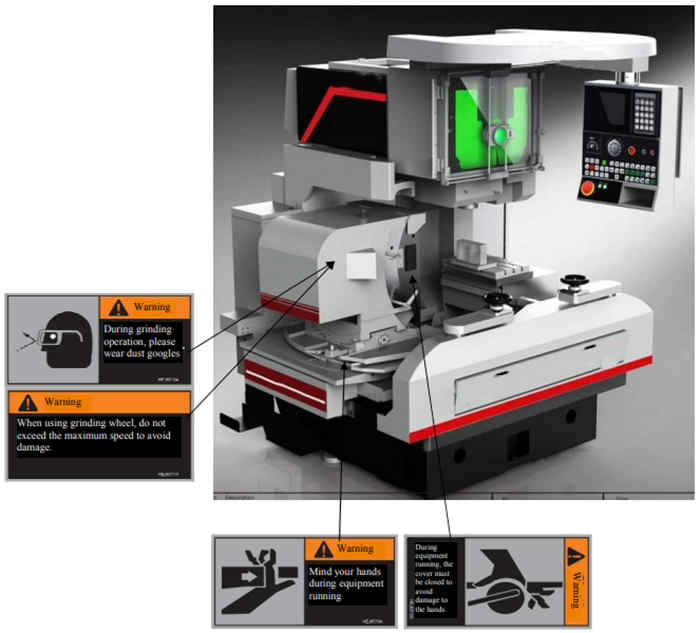

Attention When Intalling Optical Grinding Machine

When handling with rollers, please do not put the rotating shaft into the lifting bolt section.

The width upon delivery

The width upon delivery

Upon delivery, leave an additional space of about 200mm (100mm on each side) based on the following dimensions.

Move in when the projector is installed

Notes:

When handling with rollers, the full height needs to be above +150 because the rollers need to be installed at the bottom of the grinder

When handling with rollers, please do not put the rotating shaft into the lifting bolt section.