CNC optical contour grinder is composed of precision projection measuring instrument, multi-degree-of-freedom grinding head and working table, etc. It is suitable for processing all kinds of precision and complex molds, sample plates, molding tools, rollers, etc. which are hardened by heat treatment.

Constructions of Moresuperhard Optical Profile Grinding Machine

Precision digital display lifting table:

The work lifting table is equipped with precision guide rails inside, realizing the lifting and fine-tuning display screen synchronously shows its lifting and lowering displacements.

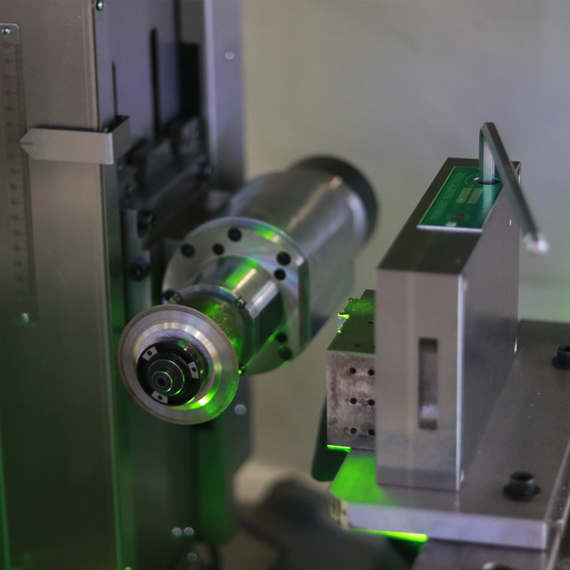

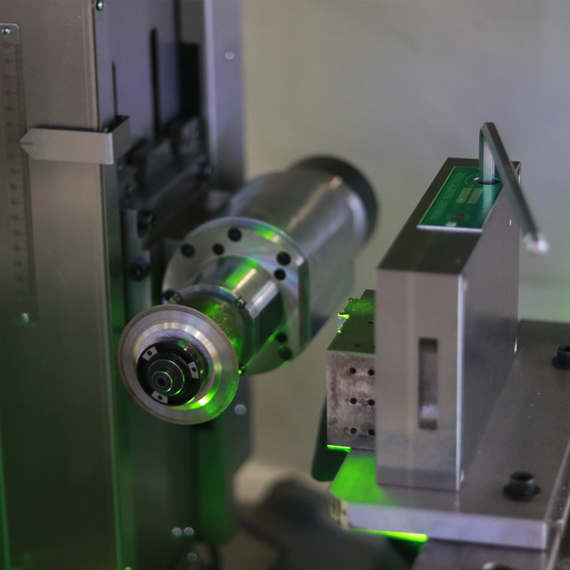

Ultra-high-speed and high-precision grinding wheel table:

The grinding wheel table is equipped with high-precision and high-resolution (0.0001MM) scales, full closed-loop control, realizing ultra-precise feeding.

Base bed rigidity design:

Newly developed base bed bearing direction reinforcement plate arrangement to solve the central part of the bending, to ensure the precision of the base body.

Control system:

Adoption of 10.4-inch display and newly developed easy-to-operate software helps high-precision machining.

4-axis linkage (2-axis interpolation) machining can be realized, which improves the machining efficiency of array graphics and batch parts.

High-speed reciprocating grinding wheel elevator with long stroke:

Long stroke 150mm high speed reciprocating 500min-1 wheel elevator enables machining of more parts. Three angles of freedom

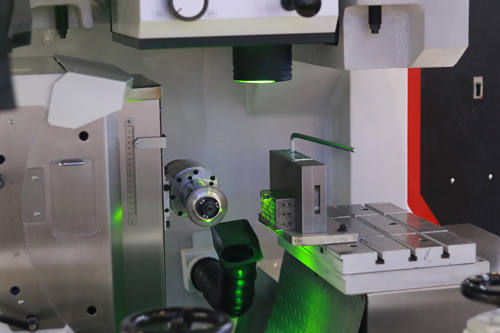

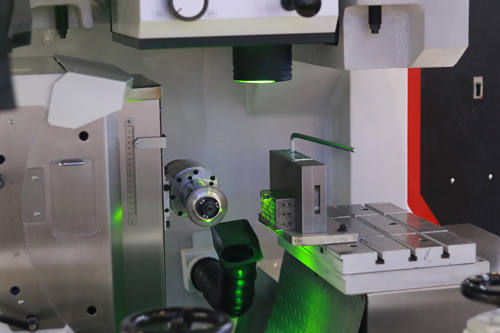

Compact high-precision projection system:

With 20X,50X switchable projection light and downlight are adopted energy-saving LED light source to prolong the service life.

Features of Moresuperhard Optical Profile Grinding Machine

-This machine bed, links, lifting platform and other parts are high-quality HT350 castings, annealing and aging treatment to eliminate stress. The castings are calculated by finite element analysis method, and optimized design, reasonable structural strength and reinforcement of the anti- match, to provide high rigidity of the machine.

-Adopting Japan THK C3 ball screw and pre-propagation, Japan THK UP level guideway full closed-loop 0.0001mm scale feedback, to ensure the accuracy of axial operation.

-High-precision electric spindle 24000min-1.

-Precision high-precision projection system, with 20X, 50X can be switched, transmitted light, falling light are energy-saving LED light source, ultra-long service life.

-The control system can realize 4-axis linkage (2-axis interpolation) machining and improve machining efficiency.

-The machine tool with high rigidity, high precision to meet the precision electronics, carbide processing industry is the processing of precision terminal molds, LED molds, SMD, precision shrapnel cross-tools, high-precision testing fixtures of the ideal equipment.

The Workpiece Processed by Moresuperhard Optical Profile Grinding Machine:

Optical profile grinding wheel is used for precise grinding mould and die, punch pin, optical grinding and form grinding cutting tool ( such as end mill and reamer) and precise instrument.