In the age of digitalization, the image quality of photos has been greatly improved compared to the past, many photography enthusiasts seek to take photos that are closer to what they see with their own eyes. However, traditional spherical lenses alone can no longer make up for this, and therefore optical systems have developed lenses that combine spherical and aspherical lenses.

Most people think of lenses as "polished", but aspherical lenses cannot be polished at the same time as spherical lenses; they can only be polished one piece at a time, which makes them very expensive.

There are

four methods for producing aspherical lenses for cameras:

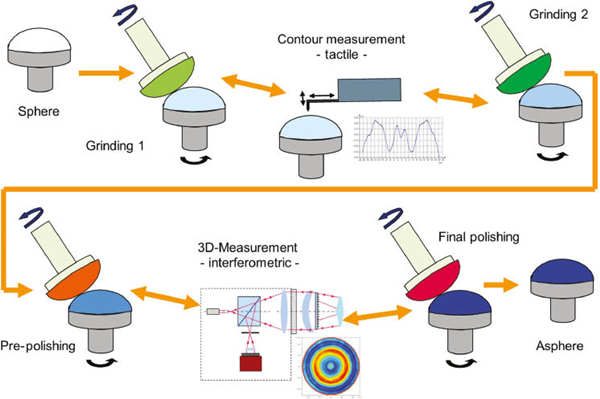

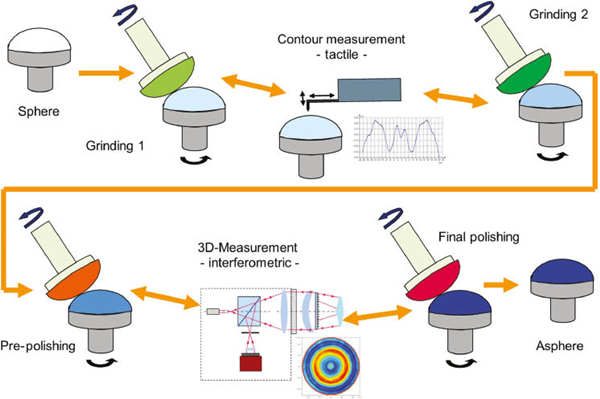

Numerically controlled grinding and polishing:

While it is possible to choose from a wide variety of glass materials, crystalline materials such as CaF2, etc., and there is no limit to the number of abrasives that can be utilized for large aspherical surfaces with high added value, the cost will inevitably increase due to the fact that they are all processed individually.

In the exposure machine used for the production of semiconductors, the aspherical surface processed by sodium chloride crystallization is the same processing technology, and the target dimensional accuracy is obtained by alternately repeating the processing and precision measurement through numerical control (NC), and correcting the errors, and therefore the unit price is higher.

Glass molding method:

Glass lenses can be further reduced in cost by producing glass molds through large-scale press molding, but it is limited to low softening point glass materials that are easy to thermoform. The mold material uses cemented carbide, CVD-SiC, and the dimensional accuracy is strictly required to be 0.1µm or less in PV, so it is not the molded lens that needs to be polished, but the "mold".

Copy method

Resin molding method:

The copy method and resin molding method are mostly used for more affordable camera lenses, not monocular camera lenses.

Usually lenses with a high aperture number have at least one aspherical lens, which is more expensive because it can render finer picture details. Longer zoom lenses can also be made with multiple aspherical lenses to shorten the length as much as possible. If a lens made with multiple aspherical lenses is sold at a reasonable price, it must be a product made by the glass molding method.

The purpose of aspheric lens grinding is not only to process the target size accuracy, but also to shorten the processing time and not to deform the workpiece in post-processing, it is necessary to complete the grinding with minimum removal and fine surface roughness, for this reason, it is necessary to prepare tools suitable for grinding the glass material, metal bonded grinding wheels have the advantage of less abrasion, but the roughness of processed surfaces is not good; resin bonded grinding wheels are more abrasive, but the surface roughness is not good; resin bonded grinding wheels are more abrasive, but the surface roughness is not good. Metal bond grinding wheels have the advantage of less wear, but the roughness of the processed surface is not good; resin bond grinding wheels have the advantage of more wear, but the surface roughness is good.