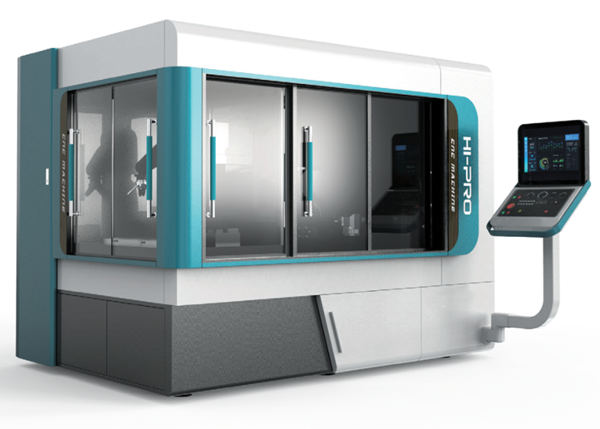

The world's manufacturing industries are not inseparable from the CNC inserts grinding machine, including general machinery, automotive, aerospace, energy, medical, rail transportation, molds, machine tools and other industries highlighted. CNC cutting tools are industrial manufacturing "teeth", whose precision, hardness, materials, etc. can directly affect the machining efficiency and cost, but the current high-end CNC cutting tools are mainly dependent on imports. CNC indexable insert peripheral grinding machine is mainly used for the peripheral grinding of cemented carbide indexable inserts and ceramic indexable inserts, adopting full automation, suitable for mass production, Moresuperhard's equipment has a superb function to complete the periphery of the insert and the negative chamfering of the insert grinding in one clamping to realize one-time completion of the entire processing. The HP-350/HP-400/HP-400plus would be undoubtedly the stars of the market with the highest possible grinding accuracy and stability in terms of performance and unrivaled flexibility.

HP-350/HP-400/HP-400plus series of CNC indexable insert grinding machines, absorbing advanced technology from home and abroad in terms of machine structure design and manufacturing technology, developed according to the modular design method, with a wide range of machining processes, high precision and productivity, are precision CNC machine tools integrating modern mechanical, electrical, hydraulic and pneumatic technologies.

1. Super strong function of CNC inserts grinding machine

The grinding of blade periphery, negative chamfer and chipbreaker groove can be completed in one clamping, and the brand-new motion design realizes the completion of all the processing of complex geometrical shapes in one clamping.

2. Perfect performance of CNC inserts grinding machine

Get the highest possible grinding accuracy and stability, unparalleled flexibility, help customers develop new products faster, reduce costs. hp-400plus is equipped with Spanish FAGOR 8070 CNC system, Windows-based platform operating system, higher openness and computing speed, workpiece machining program verified by HP-350, imported and ready to use.

3. Advanced drive technology of CNC inserts grinding machine

The feed axis adopts advanced direct drive technology, which reduces the mechanical transmission error and mechanical wear, and the high torque direct drive motor with absolute value full closed-loop feedback ensures the fast response and high-speed operation of each axis, realizing high-precision and high-efficiency machining.

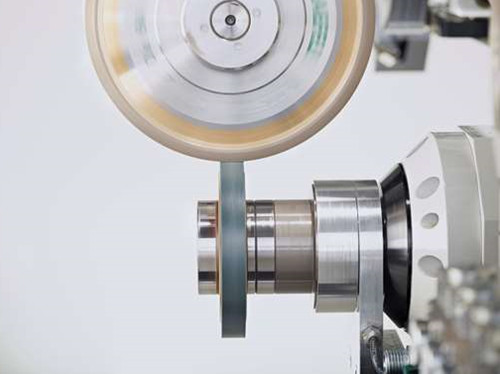

4. Synchronized electric spindle of CNC inserts grinding machine

The grinding wheel spindle adopts synchronous electric spindle technology, the unique constant torque control, so that the spindle motor can guarantee constant torque regardless of the working speed, to ensure the optimal rigidity, shock resistance and durability of the spindle mechanism.

5. 400mm grinding wheel diameter of CNC inserts grinding machine

The 400mm grinding wheel makes the grinding process more stable, and different shapes of grinding wheel flanges can be selected according to the products to be ground.

6. Measuring system of CNC inserts grinding machine

Measuring system is integrated in CNC axis, which can realize automatic centering, position correction, measurement and compensation of dimensions, inspection of processed blades, separation of unqualified products with manipulator, and also measurement of blade thickness to ensure the machining accuracy of negative chamfering on both sides.

7. Fast and highly flexible manipulator unit of CNC inserts grinding machine

Highly flexible 6-axis manipulator makes blade loading and unloading more efficient, and can optimize its own movement.

8. Dressing for grinding wheels of CNC inserts grinding machine

Newly designed online cleaning and external dressing unit combine to ensure the flatness and sharpness of the grinding wheel and higher efficiency in grinding ceramics, CBN and other super-hard materials.