How to judge the advantages and disadvantages of diamond is what every practitioner should know the professional knowledge. The following briefly discusses several important indicators to judge the quality of diamond. May it will help you when you choose the diamond materials to some extent!

a. Impact Strength

Many years ago, static compression strength has been used to measure the quality of diamond in China, but this test method has poor representation, large human error and unscientific testing mechanism. At present, the impact strength is basically used in the industry. TTi (impact strength at room temperature) is used to simulate the actual state of impact and friction of diamond in use, so as to test the cold impact strength. Ti (thermal impact strength) measures Ti by heating the diamond to 1100 degrees and cooling it, taking into account the frictional heat generated by cutting the diamond after it is made into a saw blade. Impact strength is a scientific and comprehensive quality index.

b. Magnetic Susceptibility

b. Magnetic Susceptibility

Due to the use of metal as catalyst in diamond synthesis, diamond contains different diamond impurities, especially the inclusion in the crystal, which makes diamond magnetic. The determination of magnetic susceptibility is simple and non-destructive, characterizing the impurity, toughness, strength, specific gravity, thermal stability and other properties of diamond, which has important practical value. The less the impurity content, the smaller the magnetic susceptibility, the smaller the specific gravity, the lighter the color, the better the transparency, the higher the impact toughness, the smaller the fragility.

c. Color

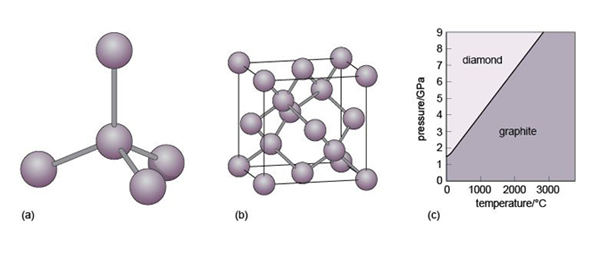

The color of diamond crystals is affected by temperature and chemical environment. When the temperature is low, the color of diamond crystal is dark, and when the temperature is high, the color is light. The color of diamond is determined by various trace elements (impurities) during crystal growth. For example: a small amount of boron will make diamond crystal sky blue, containing boron is more black (commonly known as black diamond). Nitrogen enters the diamond crystal to form yellow diamond, and most artificial diamonds are of this kind. Aluminum prevents nitrogen from entering the growing diamond crystal. Make the diamond crystal colorless. (natural diamond color).

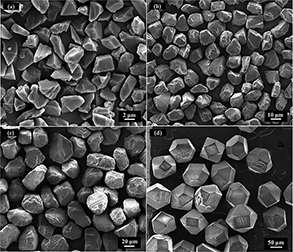

d. Granularity

Concentration degree, uniformity and tolerance range of diamond particle size are also important indexes to judge the quality of diamond. You can see the size of the particle by looking at the microscope. It can't be too big or too small. The concentration of particle size should be high, and the tolerance range has a great influence on the electroplated diamond tools. If the tolerance requirements are involved in the electroplated diamond tools, the relevant tolerance requirements should not be less than the range in this table, otherwise the error of the diamond itself will cause the overall requirements of the tools to be substandard.

e. Transparency

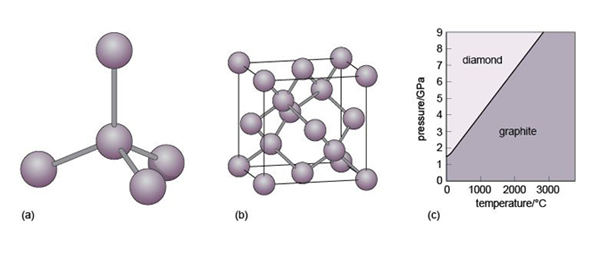

When diamond is synthesized at high temperature and pressure, the crystal core grows at the junction of graphite and metal catalyst first. If the crystal growth is too fast, the metal will be wrapped in the diamond crystal, forming small black spots of impurities. Due to the poor thermal stability of impurities, when heated, they will first expand to crack the diamond from the inside, thus affecting the strength of diamond.

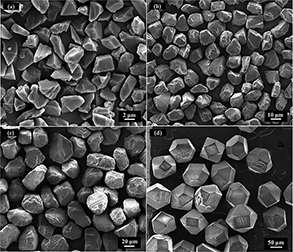

f. Crystal Structure

The growth rate and morphology of diamond crystal are more sensitive to pressure, and the high pressure leads to more nucleation, faster growth, and easy to produce octahedral crystal. Diamond crystals grown under different pressure and temperature conditions have different morphologies. Therefore, stable pressure and stable temperature are important factors for the crystal shape.

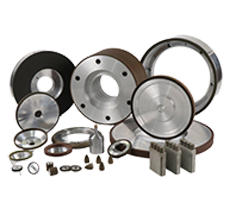

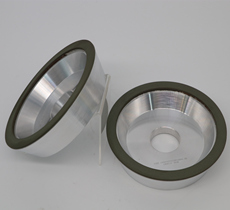

Moresuperhard provides customers with high quality grinding products, including

vitrified diamond/CBN grinding wheels, resin diamond/CBN grinding wheels,

electroplated diamond/CBN grinding wheels and

metal diamond/CBN grinding wheels. We always strictly control the quality of raw diamond materials before producing, strivingto ensure that every piece of grinding wheel that customers get has excellent and stable quality.

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about

choosing diamond materials, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!

---EDITOR: Alan Wang,Jackie Wang

---POST: Jackie Wang