Recently, Moresuperhard has received many inquiries from customers about what kind of grinding wheels the CNC spring grinding machine should use for grinding. Today, we will introduce in detail what is the CNC spring grinding machine, its matching grinding wheels, and the application field of the CNC spring grinding machine processing.

What is the CNC spring grinding machine?

Categories of CNC Spring Grinding Machines:

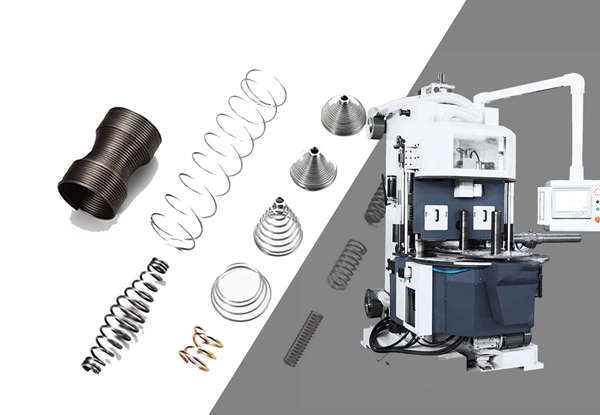

According to its functional characteristics, spring machine equipment can be divided into these categories: computer compression spring machine, computer universal spring machine and camless spring machine. The processing of industrial springs can be divided into cold rolling and hot rolling according to the rolling method. The cold rolling method means that the spring with a wire diameter below 8.0mm can be rolled under normal conditions, and the wire diameter is greater than 8.0mm. The spring needs to be coiled with a core under the heating state, which is called the hot coil method.

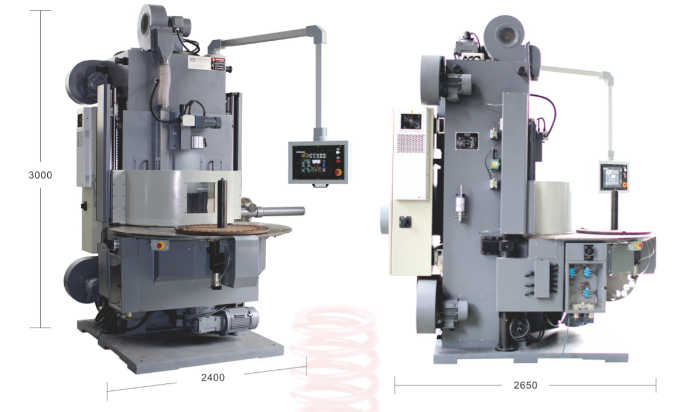

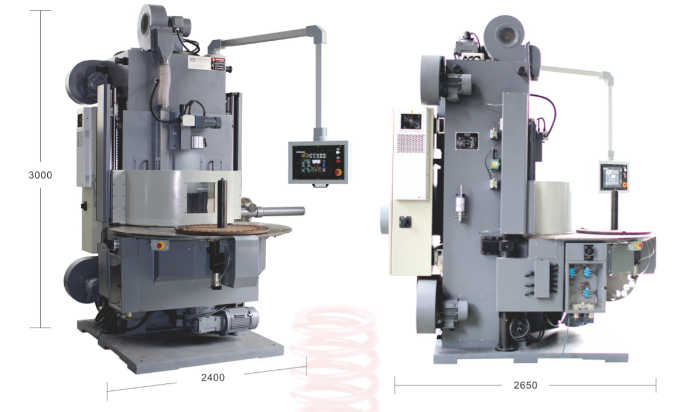

Parts and Features of CNC Spring Grinding Machines:

The CNC spring grinding machine mainly includes the headstock part, the pitch part, the forming part, the electrical part and the hydraulic part. The headstock and pitch part adopt motor and deceleration integration design to drive spindle rotation and pitch part longitudinal movement respectively. The CNC system with more than two axes has a strong expansion function. CNC spring machine has the characteristics of fast forming speed, high precision, stable performance and convenient debugging. It is widely used in various fields, such as electronics, hardware, machinery, automobiles, railways, aerospace and so on.

The Applications of CNC Spring Grinding Machines:

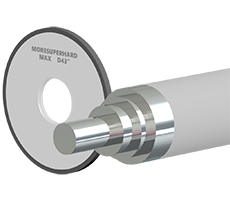

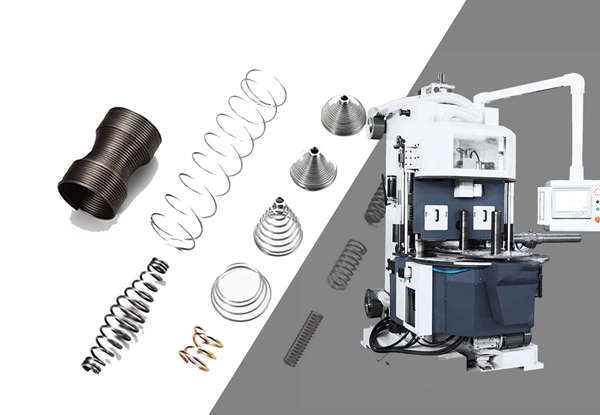

The spring grinder is mainly used to grind the two end faces of the compression spring after forming, through the specific parameters of the product to meet the specific requirements of the product itself. Reed grinding machine is also called grinder, divided into mechanical reed grinding machine and numerical control reed grinding machine, its structure is the machine tool has upper, lower two grinding head and spindle are located in the same center line. The upper and lower grinding head on the grinder is driven by two motors independently, and the grinding head feed is operated independently by two hand wheels, the feed plate is driven and controlled by a speed regulating motor alone, and the speed of the feed can be set by the manual wheel when starting the machine. CNC spring grinding machine is equipped with grinding wheel dressing device, used to timely dressing the grinding wheel face, to obtain better grinding effect, but also equipped with debris cleaning device and other auxiliary functions. Spring grinder is widely used in many fields, such as electronic spring, battery spring, thimble spring and mold spring.

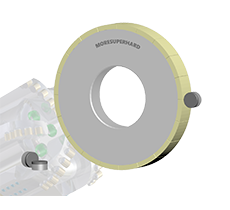

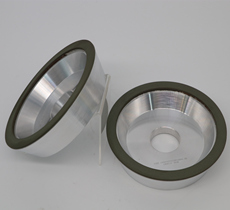

Matching grinding wheel: conventional grinding wheels such as brown corundum , diamond grinding wheel.

.jpg)

.jpg)

Processing Parts:

Spring mainly includes auto parts spring, clutch spring, tensioner spring, tensioner spring and other products.

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about the CNC spring grinding machine, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!

---EDITOR: Jim,Jackie Wang

---POST: Jackie Wang

.jpg)

.jpg)

.jpg)