How to use diamond wheel for cutting tools on pcd grinder

PCD materials are mainly divided into three categories according to the particle size:

coarse particle size (20-50μm),

medium particle size (about 10μm)

fine particle size (-5μm).

The coarser the particle size, the more difficult it is to grind. The coarse particle size tends to be jagged after grinding. , The quality is poor, but the wear resistance is the strongest; the fine-grained grinding is easier, and the quality of the cutting edge after grinding is better.

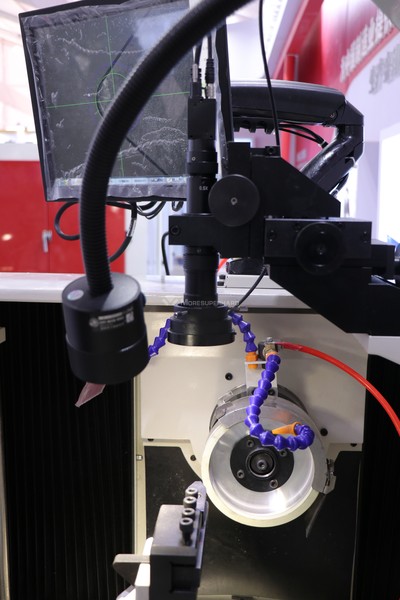

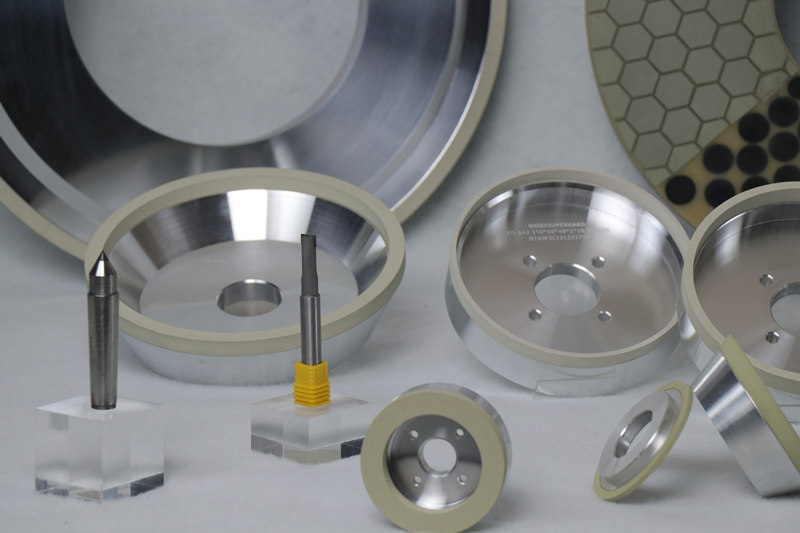

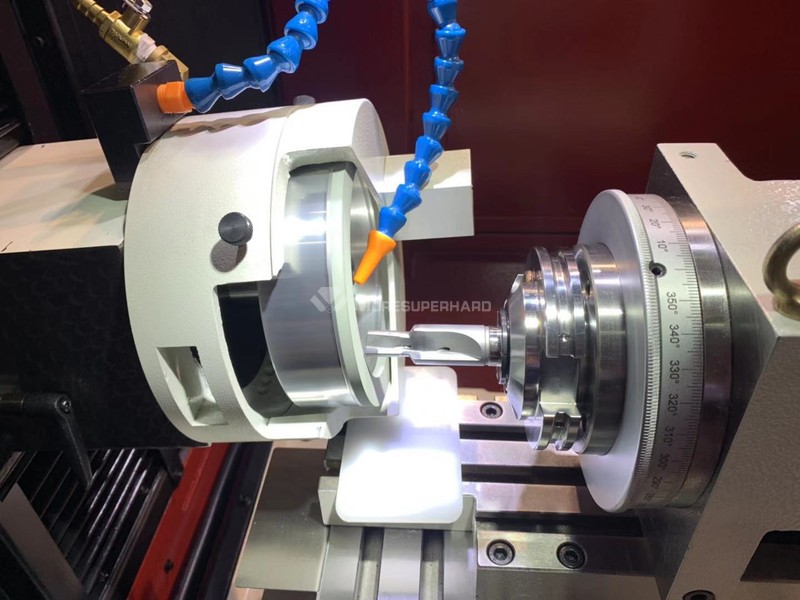

Vitrified diamond grinding wheels are used for grinding pcd cbn carbide ceramic cermet cutting tools

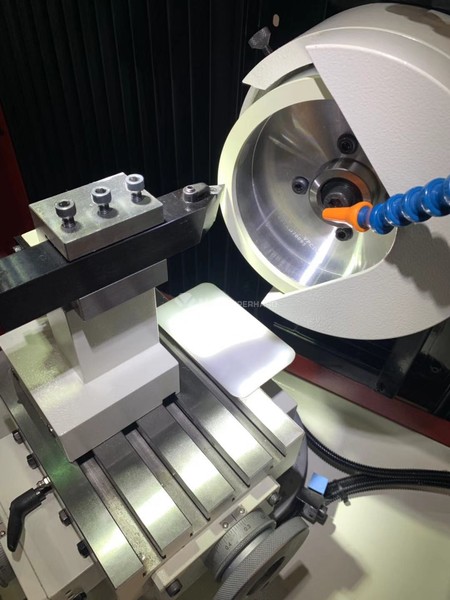

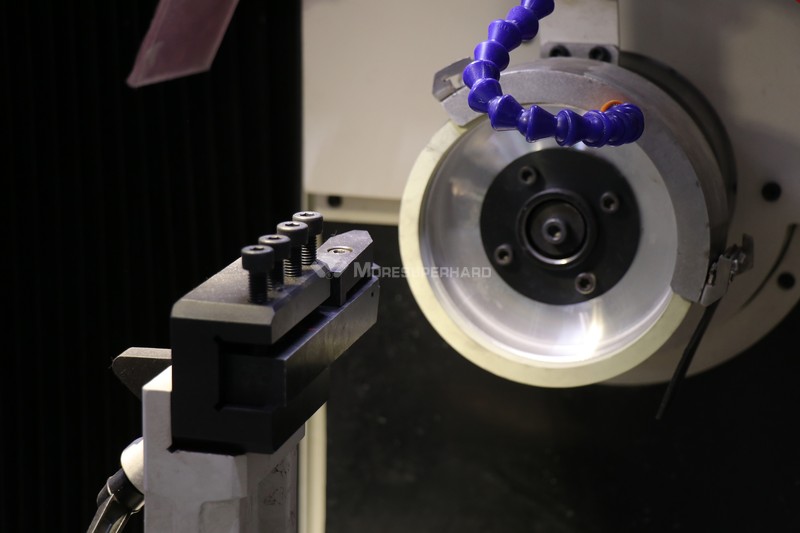

One of the purposes of cutting tool sharpening is to obtain cost-effective cutting edge quality, and the key to good quality lies in the choice of grinding wheel particle size. The finer the particle size of the grinding wheel, the smaller the chipping of the cutting edge, and the lower the grinding efficiency. For this reason, the PCD cutting tool sharpening process can be divided into three processing stages: coarse, fine, and fine according to the accuracy, use, or failure degree of the cutting edge of the tool. Formulating a reasonable sharpening process according to the specific situation can greatly improve the processing efficiency.

Classified by cutting tools edge accuracy and usage

serial number—cutting edge precision—optional grinder size—use

a coarse—0.05mm—230/270#~320/400#—Rough machining

b fine—0.02mm—M20~M40—semi-finishing

c fine—0.005mm—M5~M10—finishing