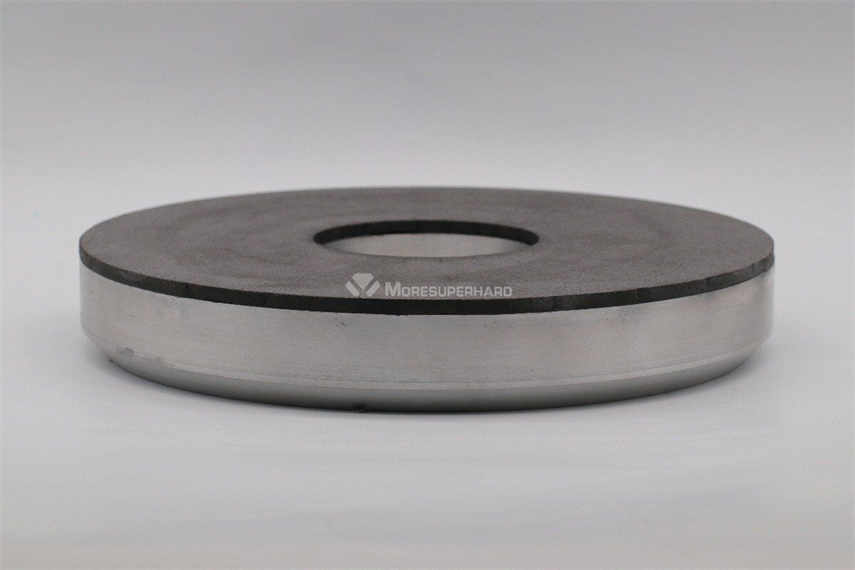

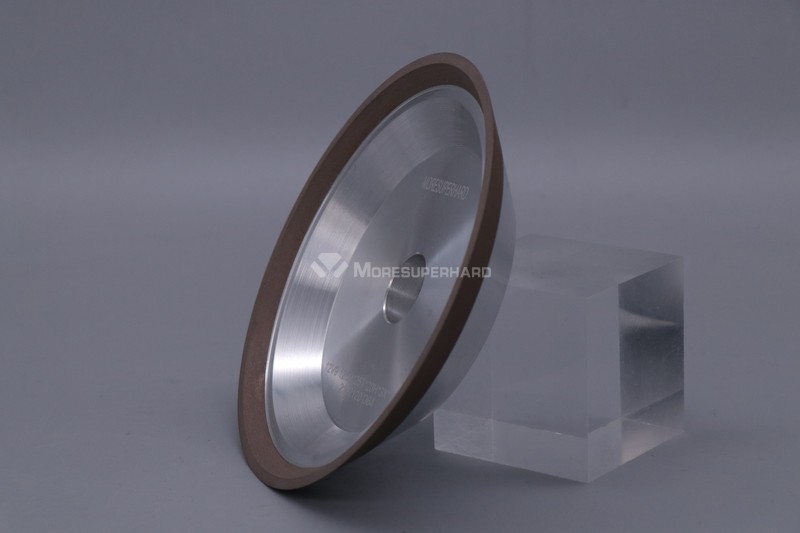

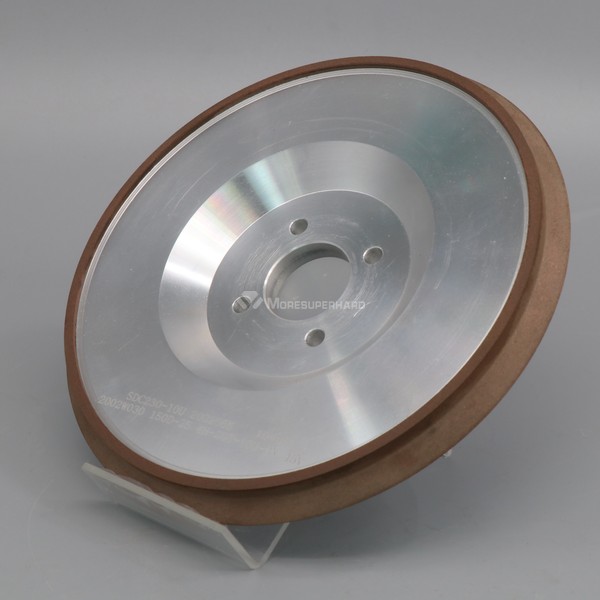

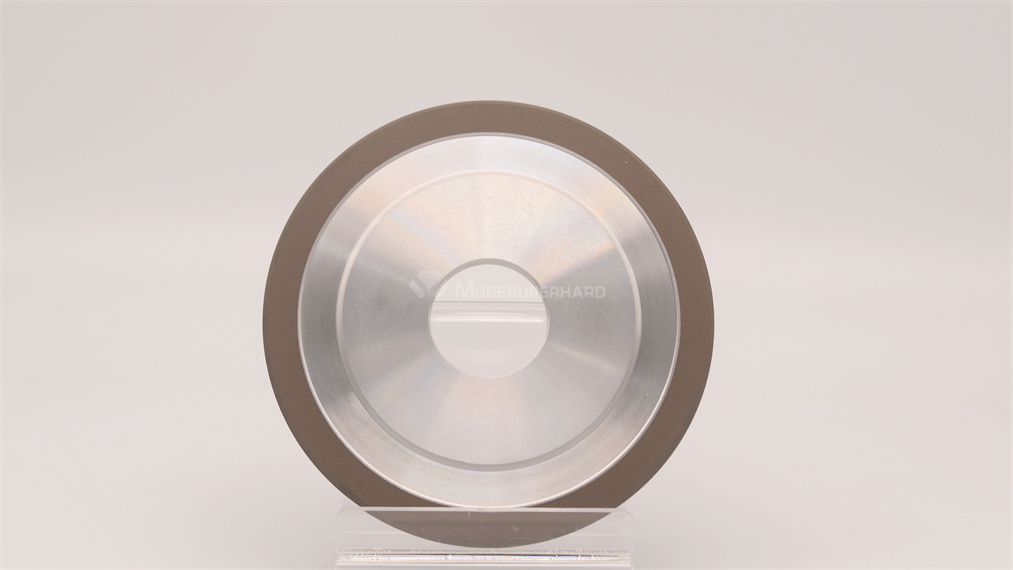

Home » Application » 1A1 Resin Diamond Grinding Wheel (D750*H305&T75*X10mm) for Processing Tungsten Carbide

Content

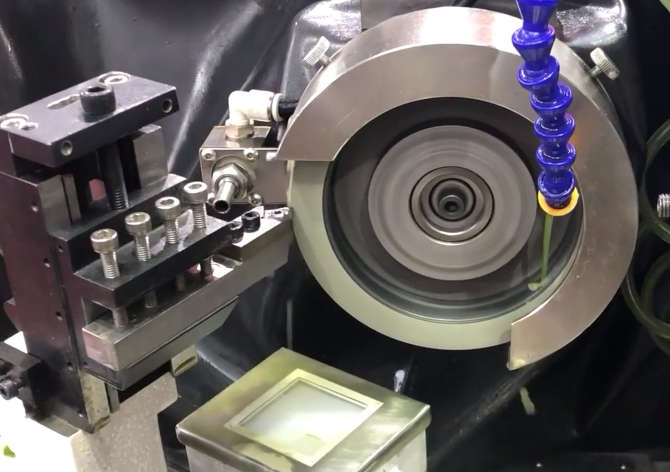

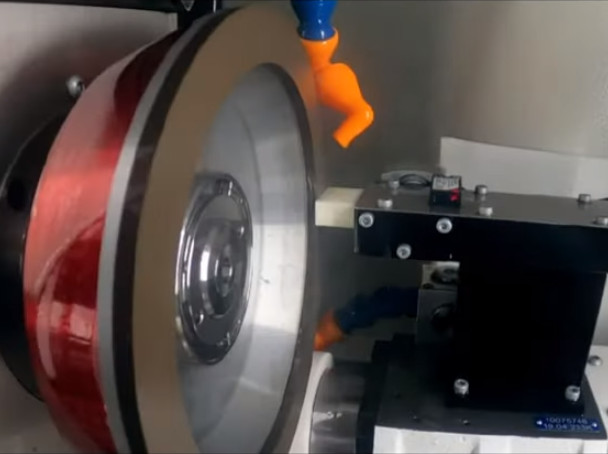

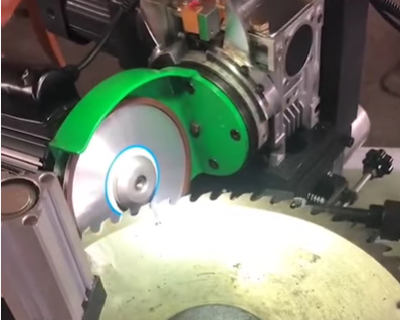

Resin diamond grinding wheels are widely used for their good self-sharpening and superb grinding efficiency, and they are very good for grinding and processing hard and brittle materials such as ceramics, glass and tungsten carbide. So, Moresuperhard suggests you choose resin diamond grinding wheels to grind tungsten carbide.

What is the resin bond?

Resin bond is an organic bond, and the grinding wheel made by this bond has high strength, certain elasticity, low heat resistance, good self-sharpening, easy production, and a short process cycle. It can manufacture grinding wheels with working speeds higher than 50m/s and very thin grinding wheels. Its application range is second only to ceramic bond, and it is widely used for rough grinding, barren grinding, cutting off and free grinding, such as grinding steel ingots, casting burring, etc.

Advantages of Moresuperhard’s resin diamond grinding wheels

* High cutting efficiency, good self-sharpening, less blocking, reducing the grinding burn occurs when the phenomenon of work

* Good flexibility will help to improve the surface roughness, mainly used for rough grinding, semi-fine grinding, polishing and other processes

* Compared to conventional silicon carbide, resin diamond wheel has good material removal rates, longer wheel life and lower grinding costs

* Resin bond diamond wheels generally remove material up to 10 times faster than metal bond wheels

Inquiry

More Application