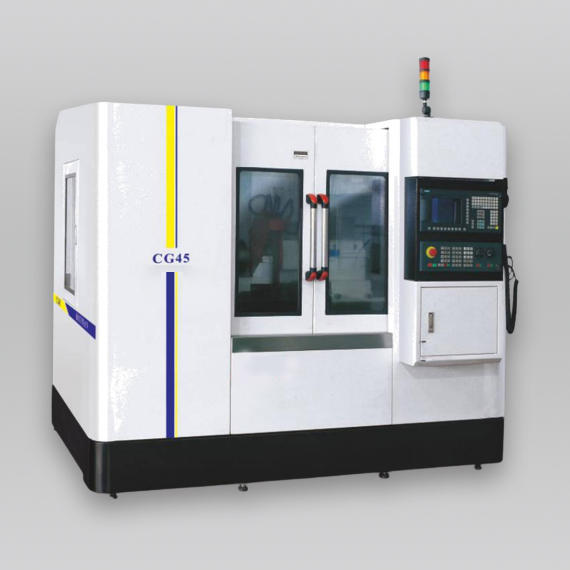

| Project | Unit | CG32 | |

| ability | Max. outer diameter of the workpiece | mm | φ200 |

| Wheel size | mm | φ405*32-60*127 | |

| Max. length of the workpiece | mm | 200 | |

| Inner diameter grinding range | mm | 6-100 | |

| Max.grinding depth | mm | 150 | |

| Workpiece clamping max. length | mm | 200 | |

| Axis mid-to-ground height | mm | 1050 | |

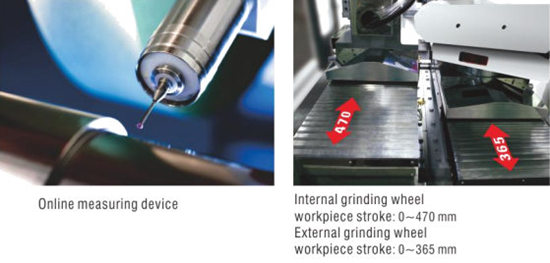

| Feed skateboard | X1,X2 axis feed | mm | 330(Option) |

| X,X2 axis max. feed rate | mm/min | 18000 | |

| X1,X2 axis minresolution unit | mm | 0.0001 | |

| Work head | Z axis fastest feed rate | mm/min | 10.000 |

| Z axis min. feed unit | mm | 0.001 | |

| Z axis min resolution unit | mm | 0.0001 | |

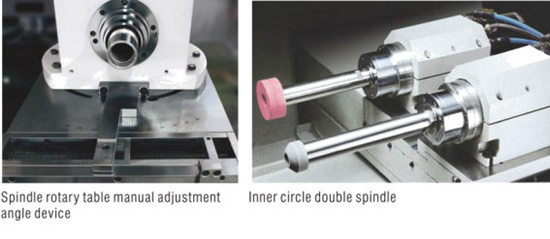

| Rotation angle | deg. | +15~-5(manual operation) | |

| Spindle rotation speed | r.p.m | 0-1000 | |

Drive motor |

X1 outer circular motor spindle | KW | 5 |

| X2 inner circular motor spindle | KW | 5 | |

| Working head drive motor | KW | 0.37 | |

| Coolant pump motor | KW | 0.37 | |

other |

Coolant tank capacity | L | 200 |

| Mechanical size(L*W*H) | mm | 1900*2053*1914 | |

| Machine weight | kg | 4.000 | |

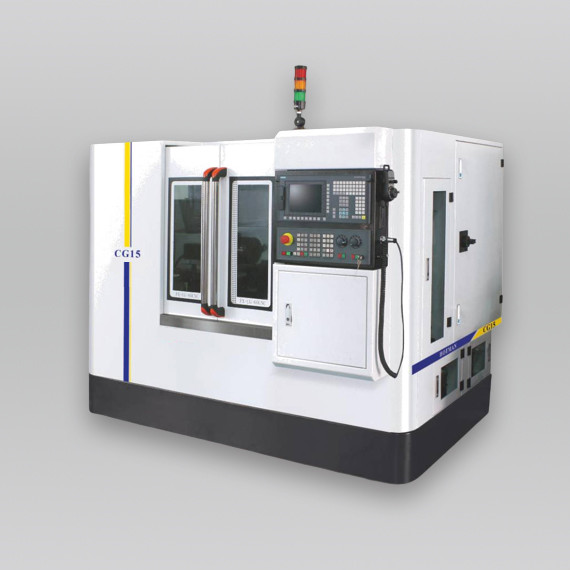

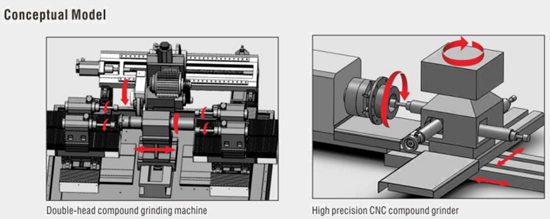

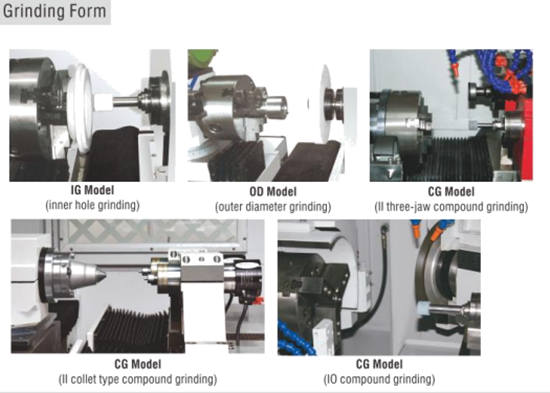

| Model Model | IG15 | OD15 | |

| Clamping workpiece dia. | φ3~200mm | φ200mm | |

| The longest workpiece it can hold | 100mm | 150mm | |

| Max. stroke | X-Axis | 330mm | 100mm |

| X-Axis | 150mm | 330mm | |

| Min. feed | X-Axis | 0.001mm | 0.001mm |

| ZAxis | 0.001mm | 0.001mm | |

| Bench speed | X-Axis | 0~10m/min | 0-10m/min |

| Z-Axis | 0~10m/min | 0-10m/min | |

| Working head speed | 0-600rpm | 0-600rpm | |

| Spindle speed | 10000~50000rpm | 7500rpm | |

Motor |

Working head | 0.75KW | 0.75KW |

| Spindle | 1.1KW | 1.1KW | |

| X-Axis | 1KW | 1KW | |

| Z-Axis | 1KW | 1KW | |

| Machine weight (about) | 3000kgs | 3000kgs | |

| Processing range | φ6-80mm(ID) | φ6-100mm(OD) | |

| Floorarea (Lx W x H) | 1900x1650x1800mm | 1900X1650X1800mm | |

| Standard accessories | 1.Spindle:90mm(10000/50,000rpm) 2.Automatic grinding wheel trimming device 3.Full cover waterproof device 4.Toolbox and accessories |

1.Automatic grindingwheel trimming device 2 Full cover waterproofdevice 3.Toolbox and accessories |

|