.jpg)

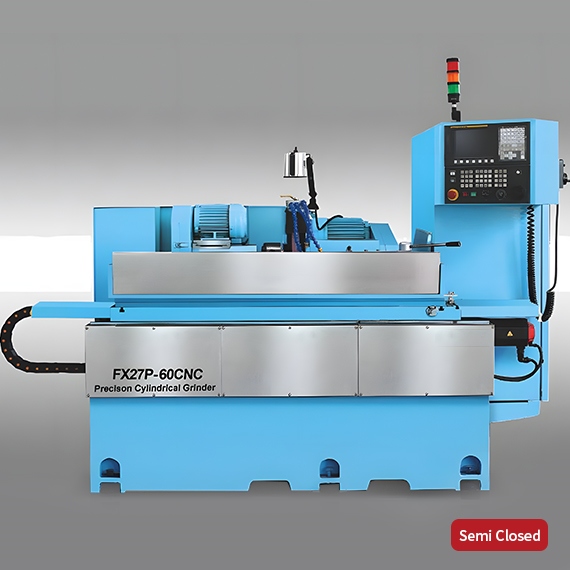

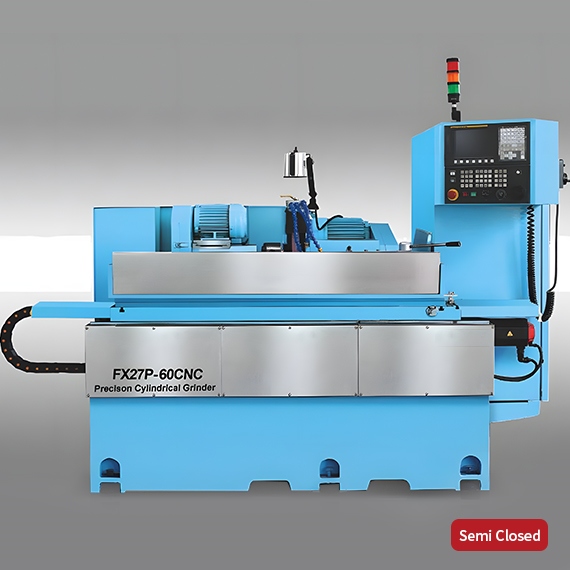

| Project | Unit | FX27P-60CNC | FX32P-50CNC | FX32P-75CNC | FX32P-100CNC | |

| ProcessingCapacity | Worktable maximum diameter | mm | 270 | 350 | 350 | 350 |

| The longest distance between two thimbles | mm | 600 | 500 | 750 | 1000 | |

| Maximum grinding diameter | mm | 270 | 320 | 320 | 320 | |

| Maximum load between two thimbles | Kg | 60(with thimble)/20(only work head) | 150 | 150 | 150 | |

| Grinding wheel size (diameter * width * aperture) | mm | 405*32-50x127 | 510x 50 x 203.2/610 x 100 x 203.2 | 510x 50x 203.2/610 * 100 x 203.2 | 510 x 50 x 127/610x 100 x 127 | |

| Wheel speed | rpm | 1650/1850/2100 | 1685/1410 | 1685/1410 | 1570/1742 | |

| Maximum line speed | m/s | 35 | 45 | 45 | 45 | |

| GrindingWheel Head | Feed angle | Deg | 90 | 90 | 90 | 90 |

| X-axis feed rate | m/min | 6 | 6 | 6 | 6 | |

| Feed stroke | mm | 270 | 320 | 320 | 320 | |

| X axis minimum setting unit | mm | 0.001 | 0.001 | 0.001 | 0.001 | |

| Head Frame | Spindle speed | rpm | 50-500 | 50~750 | 50-750 | 10-500 |

| Spindle form | Synchronization or centering | Synchronization or centering | Synchronization or centering | Synchronization or centering | ||

| Thimble | M.T4 | M.T5 | M.T5 | M.T5 | ||

| Tailstock | Automatic telescopic distance | mm | 40 | 40 | 40 | 40 |

| Thimble | M.T4 | M.T4 | M.T4 | M.T4 | ||

| Workbench | Z axis fast moving speed | m/min |

8 | 8 | 8 | 8 |

| Z axis minimum setting unit | mm | 0.001 | 0.001 | 0.001 | 0.001 | |

| Maximum stroke | mm | 550 | 500 | 750 | 1000 | |

| Rotation angle | Deg | +6/-9 | +7/-3 | +7/-3 | +7/-7 | |

| Motor | Wheel spindle motor | KW | 3.75/5.5 | 7.5/11 | 7.5/11 | 7.5/11 |

| X-axis feed motor | Kw | 2.2 | 3.5 | 3.5 | 3.0 | |

| Z-axis feed motor | Kw | 2.2 | 3.5 | 3.5 | 3.0 | |

| Headstock spindle motor | KW | 0.75 | 1.3 | 1.3 | 1.5 | |

| Cooling water motor | KW | 0.75 | 0.75 | 0.75 | 0.75 | |

| Tailstock pump motor | KW | 0.75 | 0.75 | 0.75 | 0.75 | |

| Lubricating oil pump | KW | 1/4 | 1/4 | 1/4 | 1/4 | |

| Other | Machine net weight | Kg | 3200 | 7200 | 7500 | 7500 |

| Gross weight | Kg | 3500 | 8250 | 8500 | 8500 | |

| Package dimensions | mm | 2800 x 2000x 2000 | 2800 x 2000x 2000 | 4500x3500*2500 | 4800x3800x3000 | |