Recently, many customers have proposed what is the best grinding method for processing hydraulic rods. The preferred grinding method we recommend is centerless grinding. What is the centerless grinding? how to operate it and what are the optional grinding wheels used in centerless grinding? Here,we will explain in detail for you!

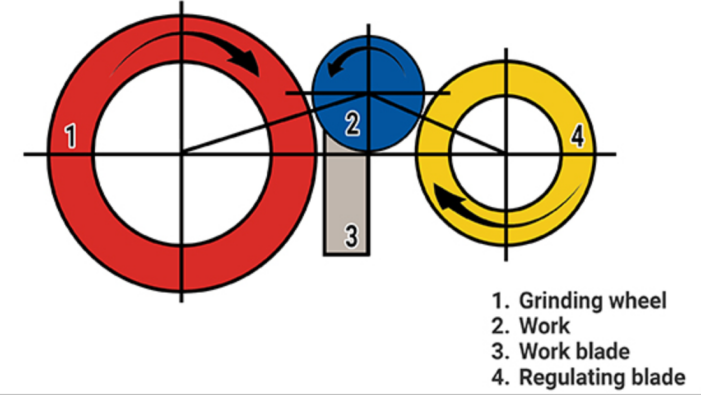

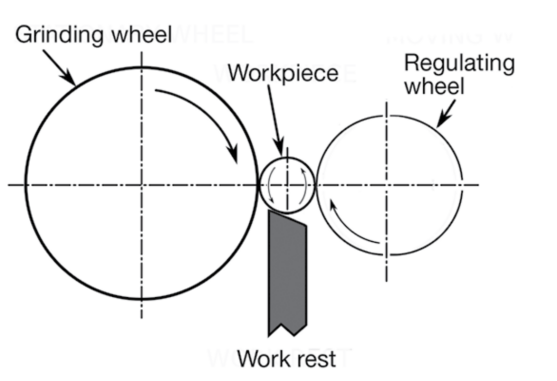

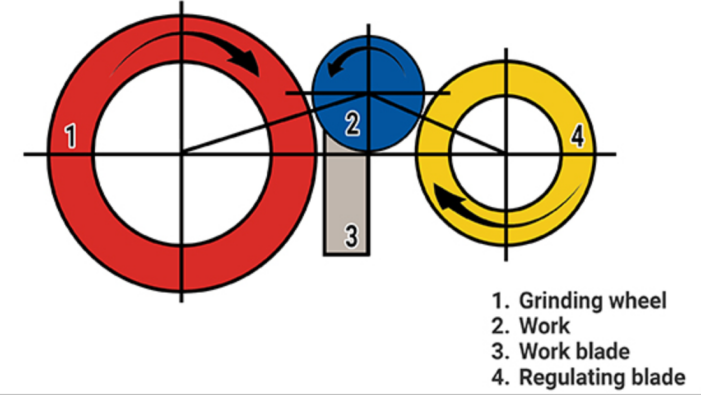

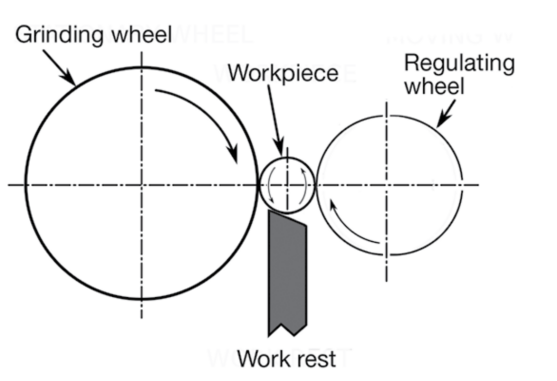

Centerless grinding has two grinding wheels, the guide wheel and the grinding wheel. The guide wheel drives the cylindrical workpiece to rotate on the pad, and the grinding wheel acts as a grinding wheel on the workpiece.

The grinding wheel, the guide wheel, and the workpiece actually rotate in the same direction at different speeds.

The grinding wheel rotates at high speed to play a grinding role, and the linear speed of the grinding wheel is very high, generally about 35m/min.

The guide wheel rotates slowly to guide the transmission, and the linear speed of the guide wheel is 10~50m/min. The speed of the guide wheel determines the rotation speed of the workpiece, and the linear speed of the workpiece is basically equal to the linear speed of the guide wheel.

In order to avoid grinding a round workpiece, the center of the workpiece must be higher than the center line of the grinding wheel and the guide wheel (15%-25% of the workpiece diameter), so that the contact point between the workpiece and the grinding wheel and the workpiece and the guide wheel is not on the same diameter line, so that the workpiece can be gradually ground round in multiple rotations.

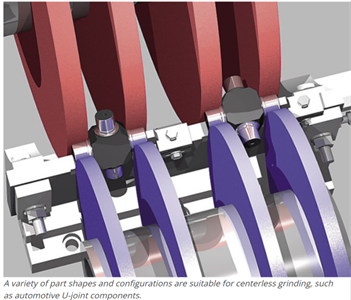

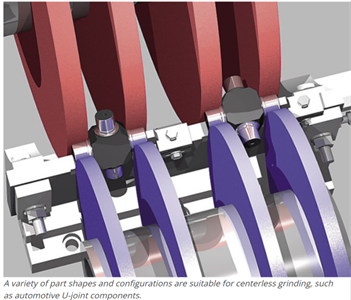

Centerless grinding is suitable for grinding slender shafts and small parts such as shafts, bushings and pins without center holes in mass production.

In fact, centerless grinding is used in a wide range of industries:

Aerospace

Agriculture

Automotive

Defense

Medical

Military

Motorsport

Power generation

Research and development

Sub-sea oil and gas

White goods

Detailed Grinding Methods of Centerless Grinding

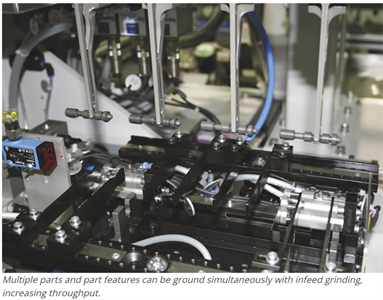

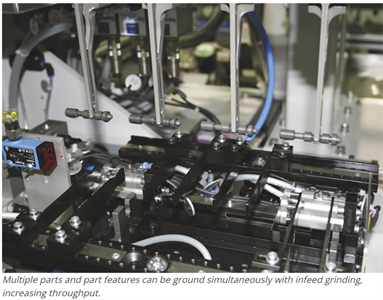

Infeed grinding plunge grinding

Infeed grinding plunge grinding

Centerless plunge grinding is a type of plunge grinding in which the workpiece is supported on the pallets with axial positioning pivots and the grinding wheel or guide wheel is plunged into the workpiece at a certain position. It is used for grinding workpieces with shoulders or tabs, cones, spheres and other rotary workpieces.

Thru-feed grinding

Thru/through centerless grinding, where the workpiece is fed in the direction of the grinding wheel axis, and the workpiece is axially fed by adjusting the slight inclination of the guide wheel axis. It is suitable for grinding long and thin cylindrical workpieces, short shafts without center bores and bushings, etc.

Thru-feed and Infeed grinding

Thru-feed and Infeed grinding is a combination of the above two types of centerless grinding. In addition, there are tangential feed grinding and end-feed grinding where the workpiece with a step moves in and out of the axial direction.

The maximum diameter of centerless grinding mentioned in the video is 500, which is quite unexpected. The diameter of the products that can be ground by centerless grinding ranges from 1.2mm to 300mm, but a diameter as large as 500 is rare. With the development of grinding machines and market demand, it should not be a difficult problem.

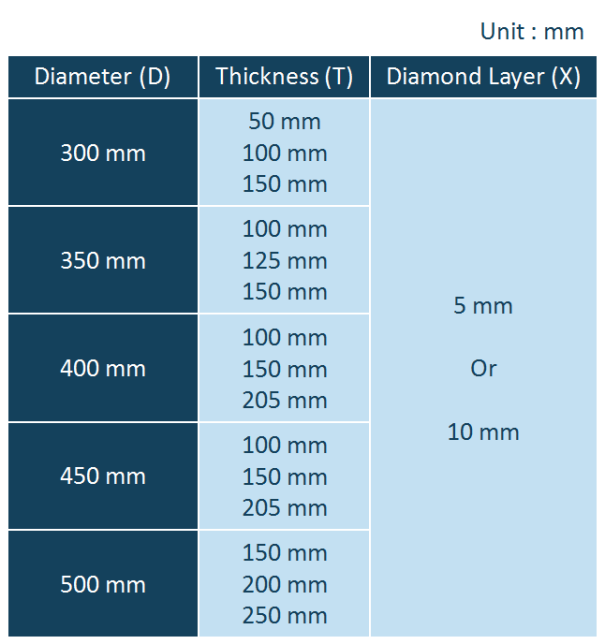

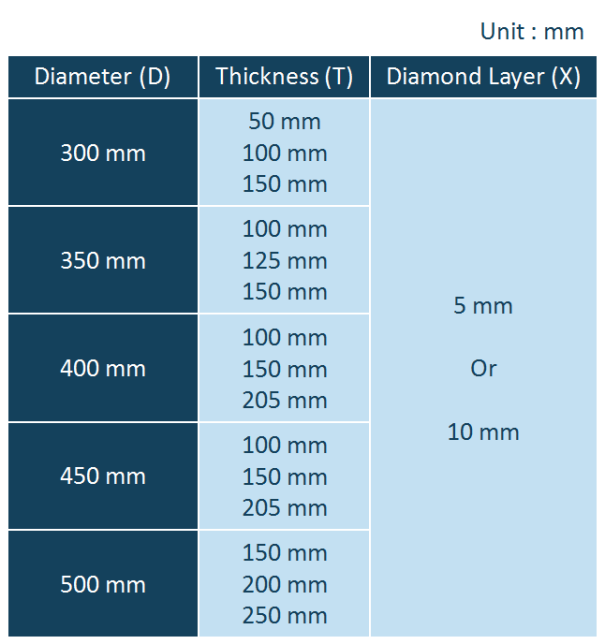

Many of the common types of grinding wheels used for centerless cylindrical grinding machines in China have been replaced by resin and ceramic super hard diamond grinding wheels. The most common specifications for resin and ceramic centerless grinding wheels are

d250-t125-h75-x10

d300*t50/t100*h127-x10

d350-t100/t125-h127-x10

d400-t100/t150-h203-x10

d500-t150-h305-x10

d600-t200-h305-x10

The following are common centerless grinding wheel sizes:

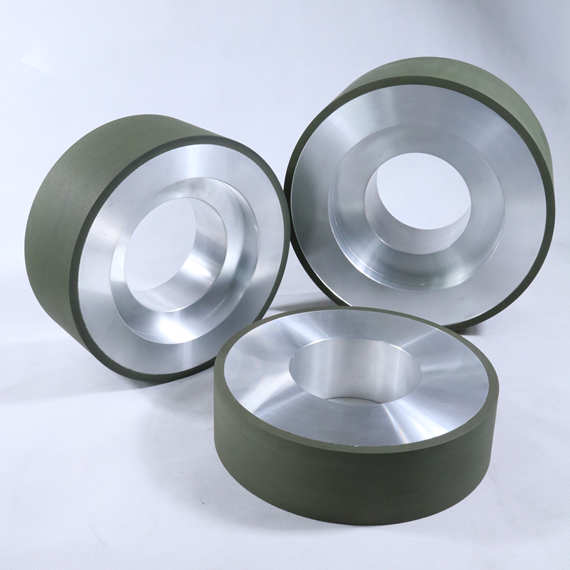

Moresuperhard's Resin Diamong Grinding Wheels

► Application

► Application: grinding carbide, ceramic, magnetic materials, stainless steel bar, PCD & PCBN compositives

► Model: 1A1 , 6A1, 9A1

► Bonded Type: Resin bond, Metal bond

► Centerless Grinder Machine: Koyo, Crystec, Dedtru, Landis , Okuma, Paragon, Royal Master, Unison, WMV

Common dimensions of centerless grinding wheel guide wheel:

Guide wheel, also called centerless grinder adjusting wheel and rubber guide wheel, acts on the grinder together with centerless grinding wheel/centerless grinding support plate; The product is made of raw rubber, rubber compounding agent and abrasive through scientific formula, molding, vulcanization and processing;

Common specifications of rubber guide wheel are as follows:

12 type rubber guide wheel 7-205 * 150 * 90 P130 E100 A180R0R 150 # - 180 # - 240#

14 type rubber guide wheel 7-205 * 150 * 90 P130 E100 A180R0R 150 # - 180 # - 240#

18 type rubber guide wheel 7-255 * 205 * 111.2 P170 E105 F25 G75 A180R0R150 # - 180 # - 240#

18B rubber guide wheel extension 7-255 * 255 * 111.2 P170 E105 F50 G100 A180R0R150 # - 180 # - 240#

18C rubber guide wheel extension 7-255 * 305 * 111.2 P170 E140 F65 G100 A180R0R150 # - 180 # - 240#

1040 rubber guide wheel type 7-250 * 125 * 75 P200 E75 A180R0R 150 # - 180 # - 240#

1050 rubber guide wheel type 7-300 * 150 * 127 P203 E75 F35 G40 A180R0R

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about

the centerless grinding solutions, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!