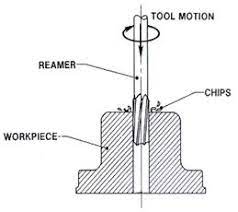

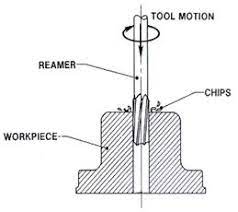

Diamond reamer is a kind of diamond grinding tool, and its cutting mechanism is similar to honing and grinding. They are abrasive micro-edge cutting, but the cutting mechanism of diamond reamer is obviously different from honing and grinding.

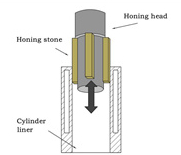

The difference between diamond reamer reaming and honing is that the diameter of diamond reamer is fixed in the reaming process after adjustment, which is not affected by the original shape and error of the processed hole, and the shape error of the processed hole can be corrected. In the process of honing, the honing stone is floating in the part hole, and several honing strips are closely attached to the hole wall under the action of elasticity. Therefore, the geometric accuracy of the inner hole before honing has a great influence on the geometric accuracy of the inner hole after honing.

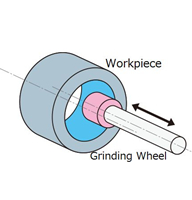

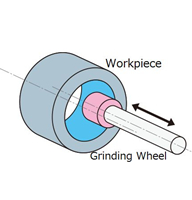

The difference between diamond reamer reaming and inner hole grinding is that when the diamond particles fixed on the surface of the diamond reamer make regular circular and axial movements during the grinding process of the diamond reamer, the diamond particle micro-edge plays the role of cutting metal effect. When grinding, the abrasive is suspended between the parts and the grinding tool, and part of the abrasive is embedded in the surface of the grinding tool, and the relative movement between the grinding tool and the parts is used to cut the metal on the metal surface. So the diamond particles fixed on the surface of the reamer body are more cutting than the abrasive rolling in the grinding process.

According to the above comparative analysis, the working efficiency of diamond reamer grinding is much higher than that of grinding or honing.

Details You Need to Know:

What are the applications of single pass diamond/CBN honing reamer?

High-precision internal hole honing, such as engine injection pump, Gears, ABS, brake cylinder, supercharger, rocker arms, connecting rod, fork, hydraulic valve body, valve sleeve, air bearing, precision gear, die guide sleeve, air conditioner compressor main and auxiliary bearings, refrigerator compressor shaft hole (cylinder hole), piston, measurement ring gauge and others.

In recent years, single-stroke honing technology has been adopted in automobile, tractor, power machinery, construction machinery, refrigeration machinery and aerospace industry.

The honing reamer is equipped with reasonable joints, tools and machine tools, which can achieve the ultra-high precision of the inner hole: Cylindricity: ≤1 μm, Roundness: ≤ 1 μm, Roughness: ≤Ra0.1, Tolerance: ≤1μm

The reamers are electrodeposited abrasive grain reamers with the electrodeposition of diamonds or CBN materials. Single-Pass is possible due to of the extremely high material extraction rates of diamond and CBN materials used as abrasive grains.

What is honing ?

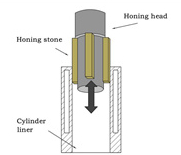

Honing is a precise process in which a group of honing stones are assembled on the honing head body, the honing stones are applied to the workpiece under a certain radial pressure, and the honing stones are processed by rotating and reciprocating motion. Honing is a finishing technique. Honing machines can be divided into vertical honing machine and horizontal honing machine.

Application areas of honing:

Honing technology came into being with the birth and development of automobiles. In order to improve the performance of engines and extend the life of automobiles, honing technology was invented. At present, honing technology has become one of the key manufacturing technologies in the automotive industry.Honing is the most important precision manufacturing technique for cylinder working surface. Honing technology not only can be used in automobile, motorcycle, tractor, crankshaft, cylinder manufacturing, and can be widely used in aircraft, missiles, tanks, tanks, artillery, ships, industrial sewing machine, air machine, hydraulic pneumatic, radar, radio and television equipment, machine tools, dies, brake oil pump, nozzle, bearings, engineering machinery, pipe and other manufacturing areas.

Honing Stones

The specifications, quantities and properties of honing stones must be selected correctly according to the material, aperture and machining requirements of the honing stones.

The specification of whetstone mainly refers to the shape and size of whetstone (length × width × height). The cross section size is generally wider than the height (i.e. B >h), so as to make the whetstone installation stable.

But when honing large-diameter holes, you can also choose stone with a square section to extend the stone's life.

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about

the grinding solutions of reaming and honing, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!

---EDITOR: Sarah Fang,Jackie Wang

---POST: Jackie Wang