Mould is the basic process equipment for industrial production. In electronics, automobiles, motors, electrical appliances, meters, home appliances, and communications, 60% -80% of parts and components rely on mold forming. The level of mold production is inseparable from the quality of the abrasive products used in the processing process. Advanced, high-efficiency, high-precision machine tools and automated production technology are used in modern mold production. The grinding workload will account for 25% to 45% of the total mold manufacturing hours.

In most mold manufacturing companies, the methods used in the finishing stage are generally grinding, electrical machining and fitter processing. Grinding has a great influence on the life of the mold, so we should pay attention to the correct selection and processing method of the grinding product when grinding the mold.

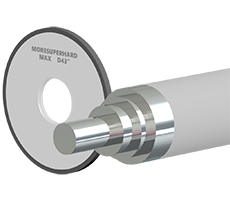

Moresuperhard has developed resin CBN grinding wheels specially for Die & Mold industry.

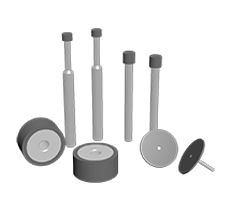

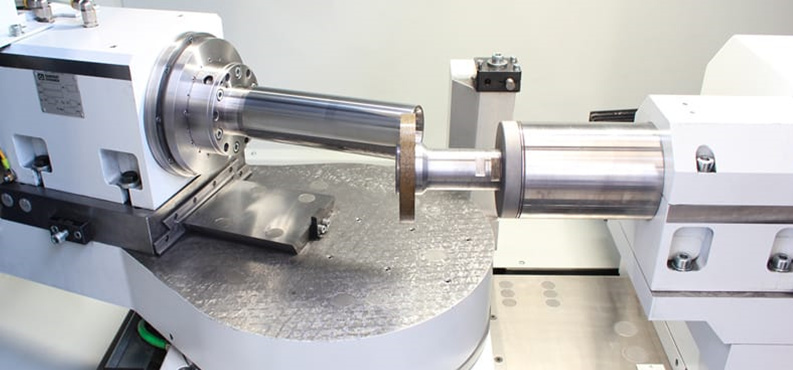

Resin CBN grinding wheel is mainly used to process stamping die and die - casting molds on the manual surface grinder. The material of mold is high speed steel (HSS).

This wheel is used for precision grinding of dies include a broad range of wheels with assorted bonds to meet varying work specifications. Moresuperhard provides the normal Aluminum Core and Steel core.

It is divided into Roughing, Finishing and Polishing. The finest grit can be 2000mesh.

Machining accuracy is very high because this wheel type is made from brittle materials. Grinding ability is very high due to pores in the wheel. This Wheel is easy to shape the grinding form by using a roller dresser (only CBN type).

Easy shape forming by a Single Point Dresser. Higher Efficiency and longer life than Normal Wheels.

.jpg) Applications

Applications

・Mold,Machinery parts,Jig, etc

・High speed tool steels・Alloy steels・Bearing steels・Cast iron, etc

Features & Benefits

Vitrified Bond CBN Wheel

■ It is possible to true and dress.

■ Due to high rigidity, this wheel can grind workpiece with high accuracy.

■ Due to strong abrasives holding strength, this wheel offers long life.

VC5P

Due to high porosity, this wheel achieves reduction of heat generation during grinding operation and is suitable for heat sensitive steels.

VCK30

This wheel has excellent cutting ability and is applicable for general purpose such as surface grinding and cylindrical grinding, etc.

VC16

This wheel is suitable for high metal removal rate with long life.

Resin Bond CBN Wheel

■ Due to its self-sharpening, resin bond wheel is easy to use and is suitable for roughing – finishing.

■ Due to moderate abrasive holding strength and wear-resistance, this wheel is suitable for roughing with free cutting.

■ Due to elasticity, this wheel using fine grits is suitable for finishing.

1. suitable for grinding ferrous metals, such as cast iron, high speed steels, and sintered iron

2. suitable for processing hard to machine materials, because CBN grains are much stronger than conventional abrasives

3. perform precision grinding because they wear much less than conventional abrasives.

.jpg)