JG Coordinate Grinding Head for Hole Grinding

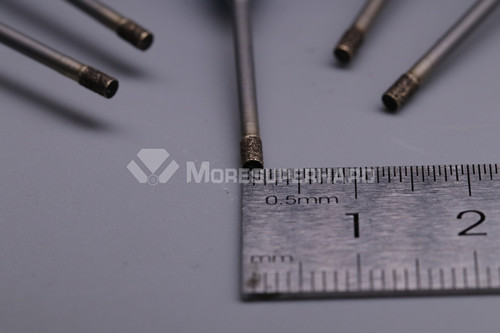

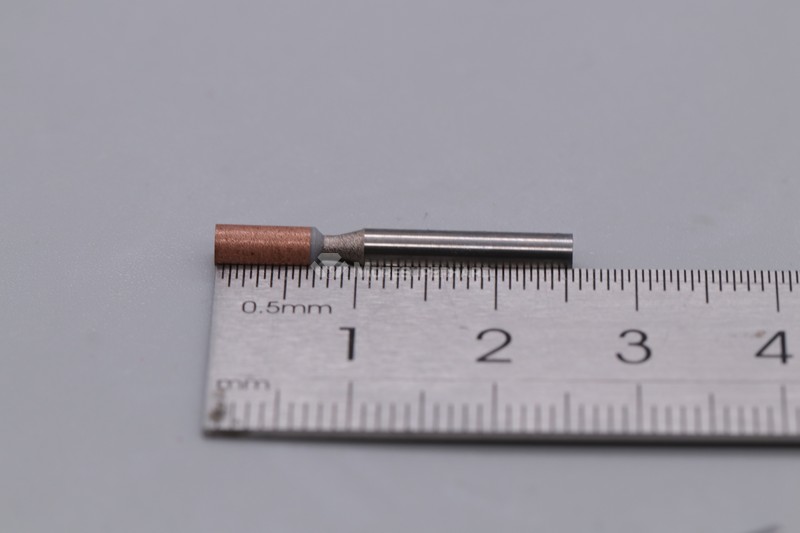

Moresuperhard high-precision electroplating CBN grinding rod (JG coordinate grinding rod) is equipped with imported continuous orbital CNC coordinate grinding machine (such as Moore Moore, Hauser Hauser, Mitsuiseiki Mitsui, Waida and Ida, etc.) to process fine molds, in the production of motor molds, leads Structural molds, semiconductor special molding molds and other fields are widely used. Products can be customized for special types according to customer requirements, such as roughing, finishing, polishing and other special requirements can be satisfied.

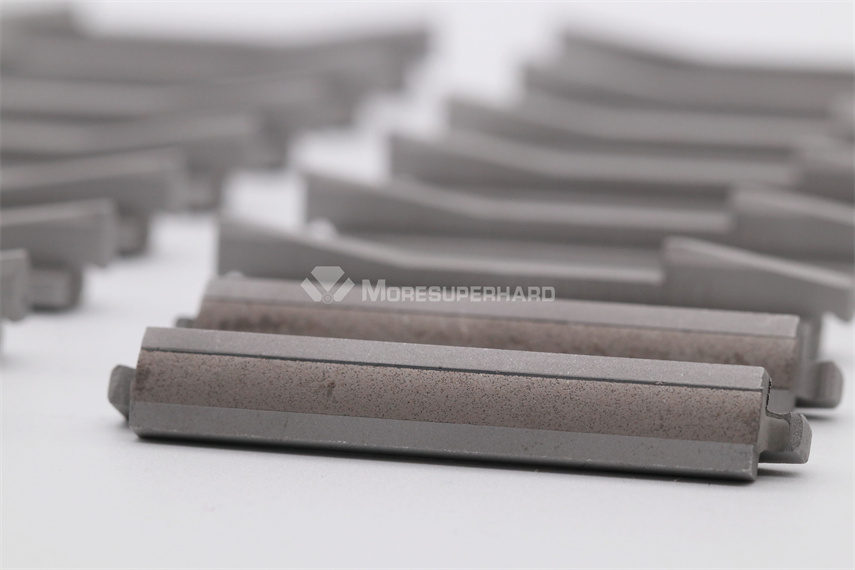

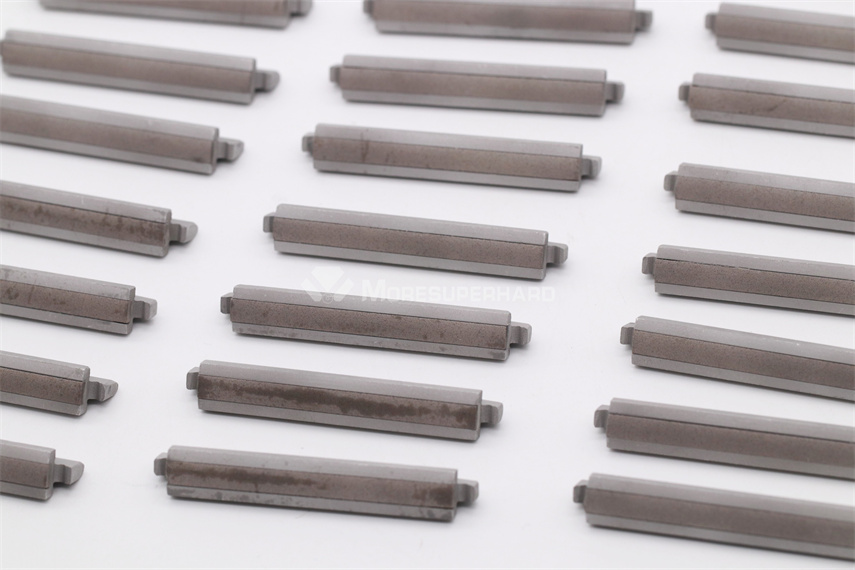

JG coordinate grinding head

Moresuperhard high-precision electroplating CBN grinding rod (JG coordinate grinding rod) is equipped with imported continuous orbital CNC coordinate grinding machine (such as Moore Moore, Hauser Hauser, Mitsuiseiki Mitsui, Waida and Ida, etc.) to process fine molds, in the production of motor molds, leads Structural molds, semiconductor special molding molds and other fields are widely used. Products can be customized for special types according to customer requirements, such as roughing, finishing, polishing and other special requirements can be satisfied. It can be processed or produced with incoming materials. The abrasive diamond and CBN are optional. The diamond grinding objects are cemented carbide (tungsten steel), ceramics, etc.; CBN grinding high-speed steel and heat-treated steel parts. JG grinding rods can also be used in CNC machining centers, small internal grinding machines, scientific research, experimental grinding machines, etc.

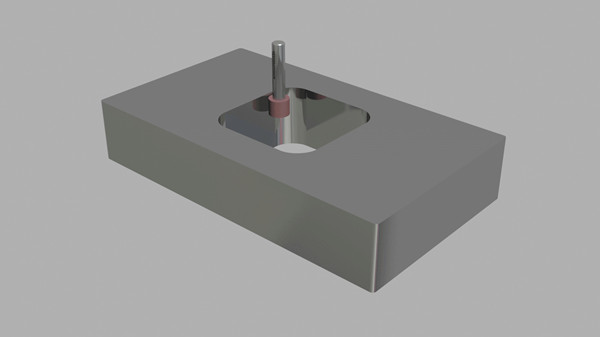

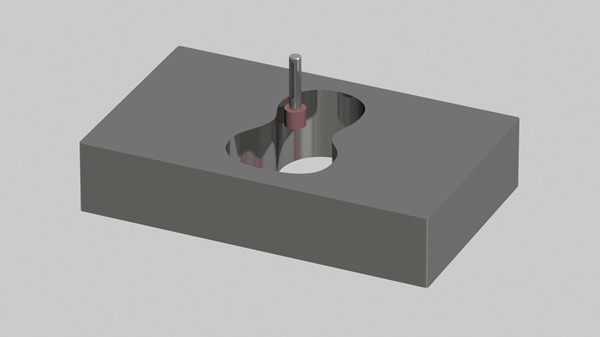

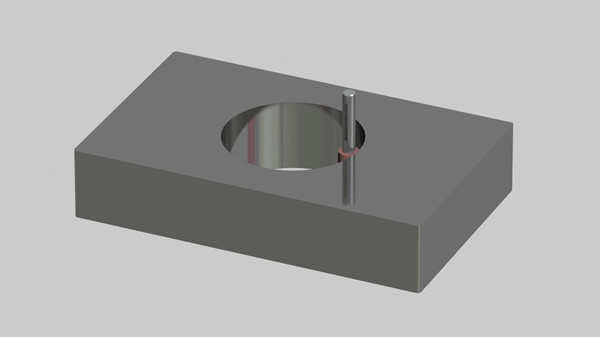

4. The coordinate grinder is a high-precision machine tool developed with the intention of eliminating the heat treatment deformation of the material. Combined with super-hard abrasives (a special grinding rod or grinding wheel for coordinate grinding), it uses a new high-speed, high-efficiency and high-precision grinding process. It is a modern fine machining. , The most useful key equipment for ultra-fine processing. Its characteristics are: coordinate grinder two-coordinate table system (fine coordinate system + fine coordinate measurement system) + high-precision coordinate grinding system, which can grind high-hardness, hardened steel and other materials. It is capable of grinding holes with high positional and dimensional accuracy, as well as various fine contour shapes.

5. Coordinate grinding, in layman’s terms, is to replace the milling cutter with an electroplated grinding head, and then control the movement of several axes of xyzc. Similar to the machining center, American Moore uses the FANUC system. It is a little troublesome to find the center for the first time. The left and right circles take about half an hour.

Coordinate grinding

CNC Coordinate Grinding Applicable Scale

1. MK4280 CNC coordinate grinder is a large standard product in the C series. It adopts a gantry structure machine tool, which improves the overall rigidity of the machine tool, and greatly improves the processing scale and bearing capacity. On the premise of further improving performance and accuracy, it focuses on improving productivity.

2. The C series coordinate grinder has the technical requirements of rough grinding, semi-finishing and fine grinding, and can complete strong grinding.

3. The adaptability of the C series coordinate grinder is greatly expanded, which meets the requirements of mass production in the fine machining workshop.

4. This type of machine tool is a continuous orbital CNC coordinate grinder. It has the functions of six-axis control (X, Y, Z, U, A, C) and three-axis linkage (any three linkages in X, Y, C, and A). Using the method of straight line and arc approximation, it is possible to process parts such as templates, mold cavities and punches with arbitrary curves and plane graphics after quenching.

5. The quenched coordinate hole system with high-precision hole spacing can be ground.