High Precision Coordinate Grinding

How many types of coordinate grinding are there? (Coordinate grinder)

How many types of coordinate grinding are there? (Coordinate grinder)

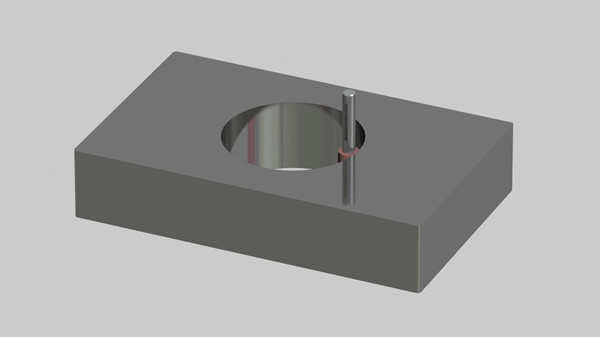

The worktable processed by the coordinate grinder is composed of a coordinate worktable and a reverse worktable. The coordinate workbench is a set of guide rail systems of high-precision rectangular coordinate system. The coordinate work table is located on the reverse work table, and the arc base for adjusting the workpiece coincides with the base of the reverse work table. During grinding, the workpiece is placed on the workbench, and the z and y coordinates can be moved and reversed, so as to carry out the forming summary and the processing of the hole.

Using a coordinate grinder, it can grind inner holes, outer circles, tapered holes, coordinate holes, stepped holes, stepped surfaces, keyways, square holes, and curves composed of straight lines and arcs. Like coordinate boring, the workpiece must be positioned and aligned before grinding. After alignment, use the vertical and horizontal movement of the worktable to make the machine tool spindle base coincide with the workpiece arc base, and then grind.

(1) Inner hole grinding

Inner hole grinding is the basic purpose of the coordinate grinder Z. The diameter of the aperture is 3 to 200 ram, and the surface roughness is R. ≤0.4 m, the roundness error does not exceed 2 m, and the straightness error does not exceed 2 m.

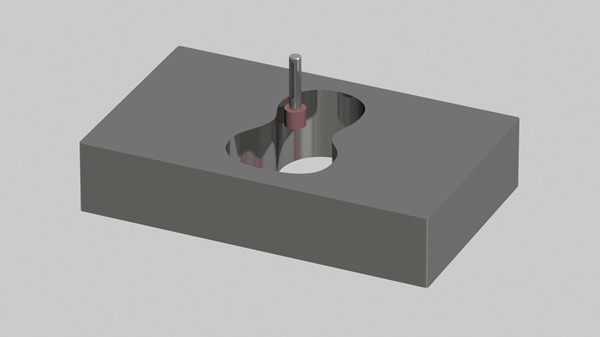

During grinding, the workpiece does not move, and the grinding wheel performs high-speed rotational motion and planetary motion. The adjustment of the aperture is accomplished by increasing the radius of the planetary motion, that is, radial feed motion.

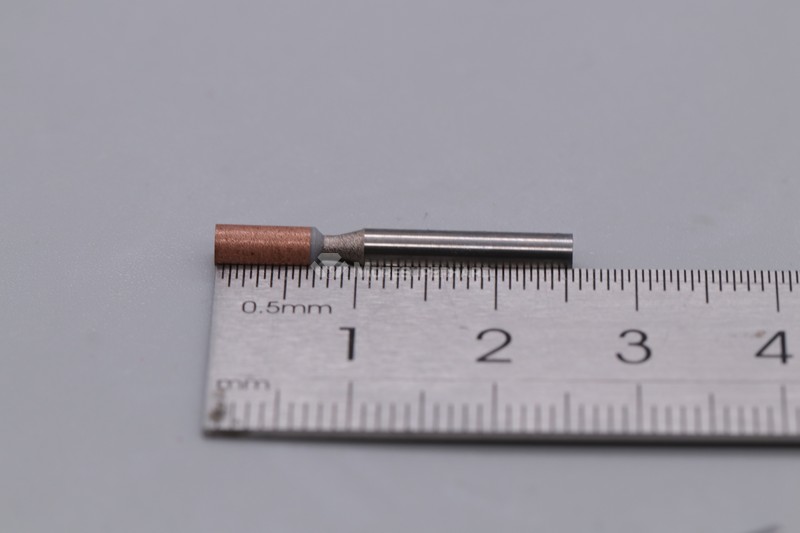

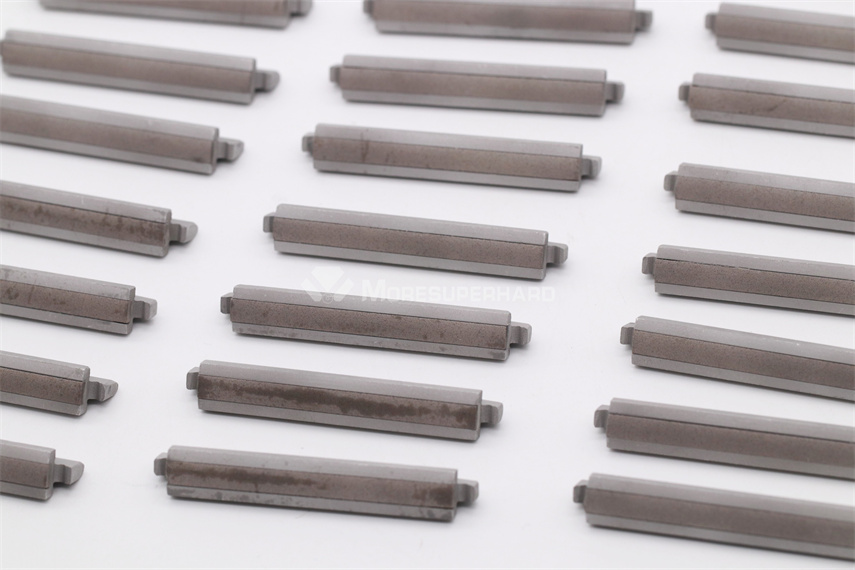

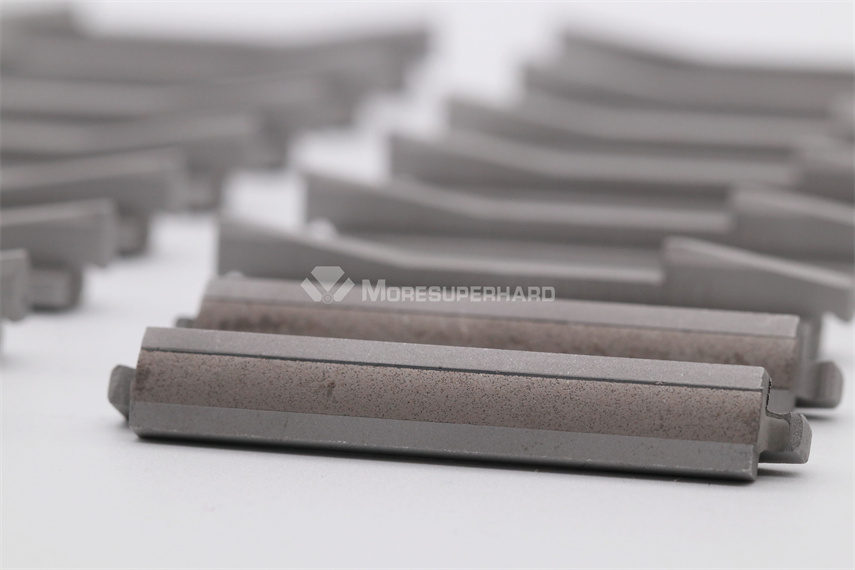

When grinding the inner hole, the diameter of the grinding wheel is related to the hole diameter of the grinding hole. When grinding small holes, diamond or cubic boron nitride sprayed grinding wheels are used, and the diameter of the grinding wheel is 3/4 of the hole diameter. In order to ensure the linear speed of the grinding wheel, the grinding wheel must be reversed at a high speed, and the smaller the diameter, the higher the speed. Therefore, a high-speed pneumatic grinding head is required, and its rotational speed is 150 000-200 000r/min. When the hole diameter is less than 8ram, the diameter of the grinding wheel should be appropriately increased, and when the hole diameter is greater than 20mm, the diameter of the grinding wheel should be appropriately reduced. Makino machining center grinding wheel diameter is about 1.5 times the diameter of the mandrel. If the diameter of the mandrel is too small, there will be grinding ripples on the grinding surface. The smallest grinding hole diameter on the coordinate grinder can reach 0.8mm.

The grinding speed of the grinding wheel is related to the abrasive and workpiece data of the grinding wheel. The grinding speed of ordinary abrasive grinding wheel is about 25-35H∥s when grinding carbon tool steel and alloy tool steel, and the grinding speed of cubic boron nitride grinding wheel is about 20-30m/s when grinding carbon steel and alloy steel. When diamond grinding wheel grinds cemented carbide, the grinding speed is about 16-25In/s.

(2) Cylindrical grinding

When grinding the outer circle, the movement of the grinding wheel is basically the same as the inner hole grinding, but the adjustment of the outer circle diameter is done by reducing the radius of the planetary motion (Figure 6-32). Surface roughness scale. ≤0.4 bucket m, the roundness error does not exceed 0.4 “m.

(3) Taper hole grinding

One of the functions of the coordinate grinder is to process taper holes. When grinding, first trim the grinding wheel to the required angle, and use the special structure of the grinding taper hole, so that the grinding wheel is fed in the axial direction, and the radius of the planetary motion is continuously changed for grinding. The radius of motion gradually increases. The size of the cone angle of the cone L depends on the ratio of the two changes, usually the cone angle is 0. One 16.