Peel grinding

Produces the final diameter.

Flute grinding

Flute grinding is the most critical, time consuming and cost intensive operation in manufacturing rotary tools.

Gashing

Creation of a taper along the cutting face to reduce the feed forces.

Clearance angle

Clearance angle reduces the contact area between the rotary tool and the workpiece. The clearance angles provide the tool with a free-cutting property and simultaneously reduce the feed forces when drilling and milling.

Relief grinding

Material is removed directly behind the cutting edge.

Profile roughing/finishing Flute/Clearance angle polishing

Polishing is made to increase tool life and quality of the end product, the drill bit or milling cutters.

Gashing requires higher profile consistency (of the grinding wheel) in comparison to fluting, due to the high edge quality required of carbide tools.

Widely used for grinding a slot or notch along the cutting face to allow for chip flow on tungsten carbide, high speed steel (HSS), stainless drill ,end mill and reamer.

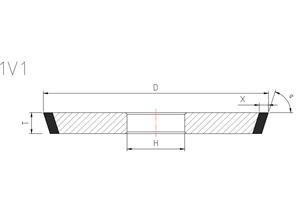

- Ultra-High Performance Hybrid Bond Construction

- Low grinding forces

- Superior surface finishes

- Excellent heat dissipation

- Reduced grinding costs

- Can be used for new tool manufacturing AND re-sharpening of carbide cutting tools

Moresuperhard Gash Grinding wheels are very effective in the gashing operation, with very large stock removal capacity and high profile consistency. And, you’ll get superior tool edge quality at high production rates.

.jpg)

.jpg)

.jpg)

.jpg)

.png)