.jpg)

.jpg)

Classification of Diamond Sanding Belt

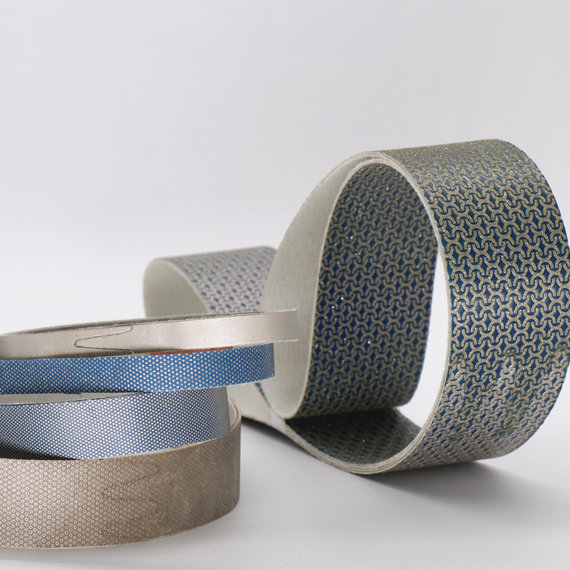

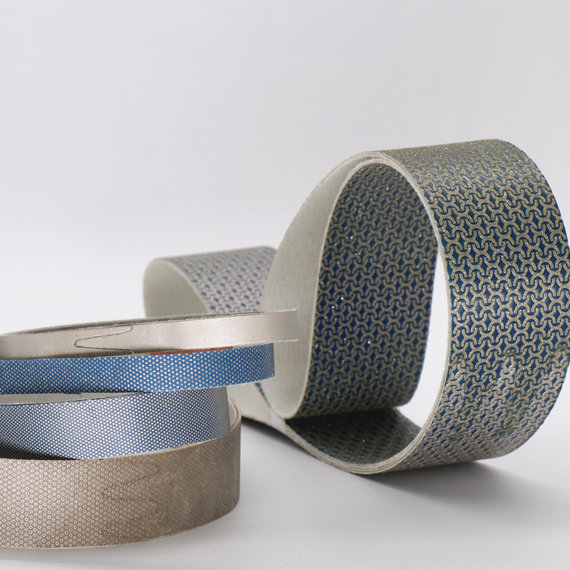

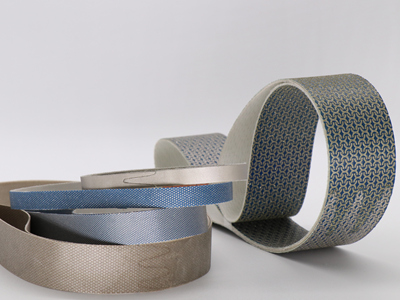

Bond: Diamond sanding abrasive belt is divided into metal nickel plating electroplated bond and resin bond, a resin bond also consists of flexible and hard type.

Pattern: There are many grinding advantages such as sharpness, durable, flexible, dry or wet grinding for diamond sanding abrasive belt with various patterns. Please choose different design patterns according to needs.

Backing Base: The main characteristics of the backing are thickness, softness, temperature resistance, and easy quickly removal. Select the backing base according to the material which will be ground.

.jpg)

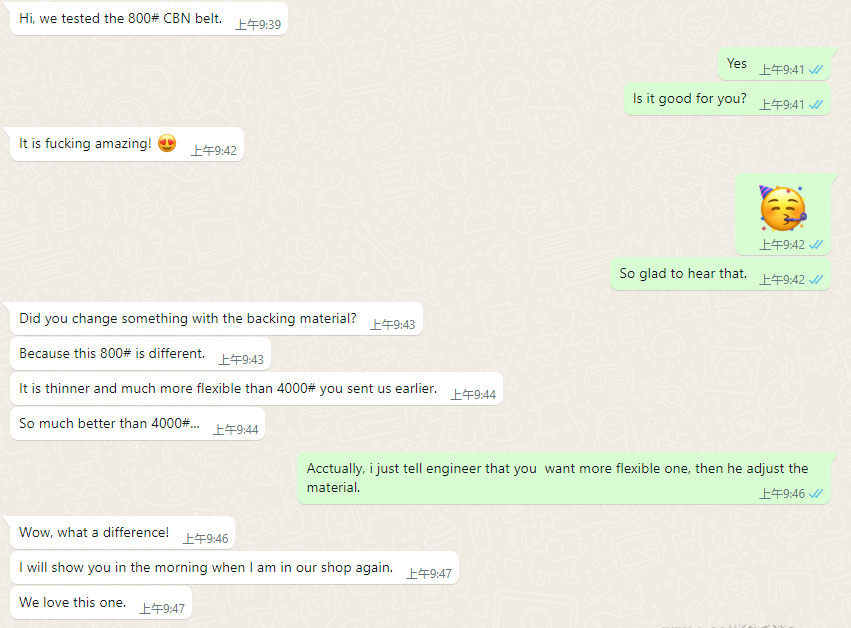

Here is the customer's feedback after testing and using our resin diamond sanding belt size 50x1500mm 4000# and 50x1500mm 800#:

.png)

He firstly made a purchase of our diamond sanding belt #4000, but he found that it was a little stiff. Because we have the ability to provide customized services for customers and our engineer made some improvements for his workpieces, so the second time he purchased the belt, he found the test and use result was amazaing!

| Length | Width | Girt | ||

| (mm) | (inch) | (mm) | (inch) | #60,#100,#120, #200, #400, #800, #1500, #2000, #3000, #5000 |

| 150 - 5000 | 6” - 200” | 5 - 350 | 1/5 “ - 14” | |

_(1).jpg)

| Workpiece diameter | 400mm*12 HVOF spraying |

| Grinding machine model | 65656 |

| Belt speed | 22 m/s (2800rpm) |

| Belt contact workpiece mode | soft contact or hard contact |

| Workpiece rotation speed | 30 RPM |

| Coolant | water or others |

| Spray coating thickness | 250μm |

| Original roughness of spray coating | Ra 0.4mm-0.6mm |

| Machining allowance of spray coating | 100μm |

| Coating thickness after processing | 150μm |