Are you in search of a high-performance, customizable solution for grinding and polishing precision components? Look no further than our premium planetary gear—engineered to meet the rigorous demands of industries working with sensitive and high-precision materials.

What Is a Planetary Gear?

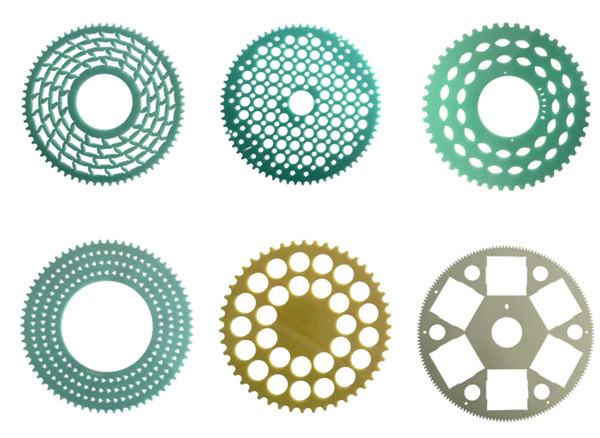

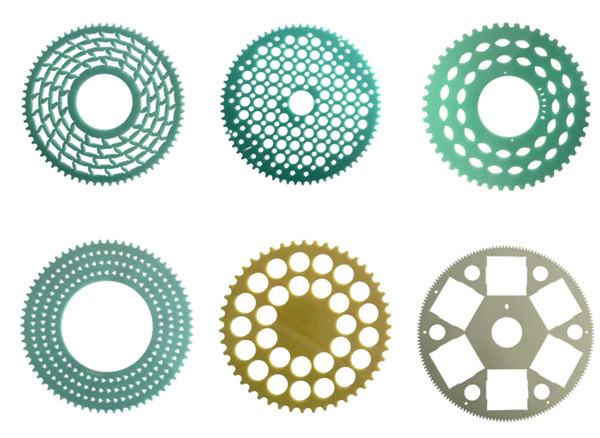

A planetary gear is a specialized gear with a toothed outer edge and multiple circular holes (designed for holding workpieces), positioned between upper and lower polishing plates. Sandwiched between the central gear (or internal gear ring) and external gear ring, it operates with exceptional stability to ensure uniform processing of your components. Our planetary gears are fully customizable in size, allowing you to get a tailored solution that fits your specific equipment and application needs.

Customization & Quotation Made Easy

We simplify the customization and quotation process for you. To get an accurate quote, simply provide us with your CAD workpiece drawing or planetary gear blueprint, along with your desired material and thickness. Our team will quickly respond with a competitive offer, ensuring a seamless experience from inquiry to delivery.

Material Options to Suit Your Needs

We offer three high-quality material choices, each optimized for different application requirements:

- Epoxy Board (Bakelite): The most popular choice, renowned for its excellent cost-performance ratio and high precision. Available in water green and yellow, it balances durability and affordability for most standard grinding and polishing tasks.

- PVC: A flexible material favored by clients for specific processes. With a lower price point than bakelite, it comes in gray and excels in applications where a softer touch is required.

- Steel (Stainless Steel & Blue Steel): Ideal for heavy-duty or long-term use, steel planetary gears offer superior durability. While they come at a higher cost, their robustness makes them a valuable investment—note that their shape is less flexible for cutting or modification.

Key Specifications

- Thickness Range: 0.2mm – 30mm (accommodates various workpiece sizes and processing requirements)

- Compatible Models: 6B – 32B (widely adaptable to common grinding and polishing equipment)

Wide Application Fields

Our planetary gears are specifically designed for grinding and polishing a range of high-precision components, including:

- Monocrystalline silicon wafers

- Optical glass

- Ceramics

- Quartz wafers

- Sapphire

Whether you’re in the semiconductor, optical, or advanced materials industry, our planetary gears deliver consistent results to enhance the quality of your end products.

Core Advantages of Moresuperhard Planetary Gear

- Superior Stability: Ensures uniform force distribution during processing, minimizing errors and improving product consistency.

- Reliable Quality: Manufactured with strict quality control to meet industry standards and withstand repeated use.

- High Precision: Engineered for tight tolerances, supporting the processing of high-precision components.

- Short Production Cycle: Fast manufacturing turnaround, with same-day delivery available for small orders—keeping your projects on schedule.

- Timely Delivery: We prioritize efficient logistics to ensure your planetary gears arrive when you need them.

Get Your Custom Planetary Gear Today

At moresuperhard, we're committed to providing high-quality, customizable planetary gears that elevate your grinding and polishing processes. Whether you need a standard size or a fully tailored solution, our team is ready to assist. Contact us now with your CAD drawing, material preference, and thickness requirements to get a competitive quote—let's power your precision manufacturing together!