MÄGERLE manufactures highly efficient grinding systems and products that are particularly suitable for suppliers to the aerospace industry and other demanding applications. BLOHM and JUNG offer high-precision standard and application-specific machines and systems for a wide range of industries and applications, from aerospace to tool making.

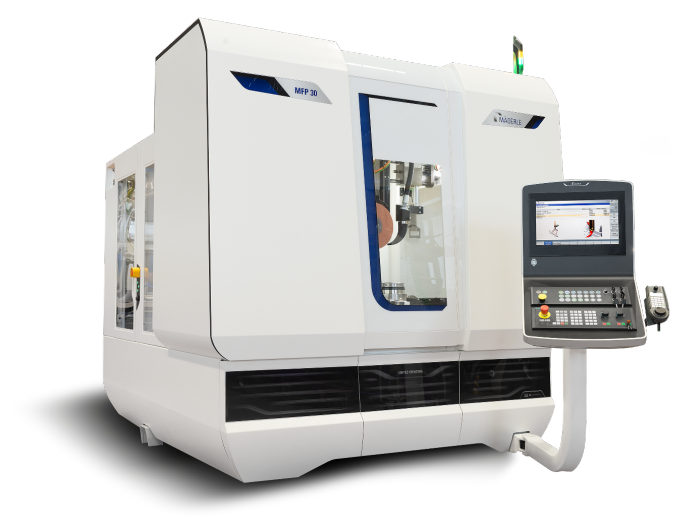

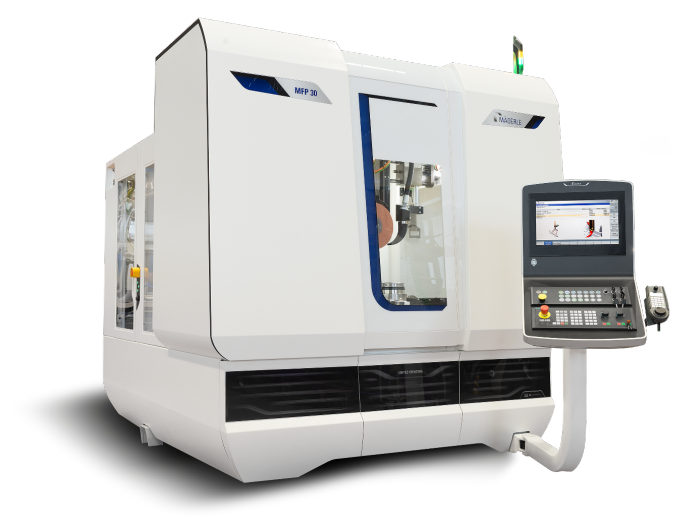

MÄGERLE MFP 30 grinding center - the compact solution for high productivity

The compact

MÄGERLE MFP 30 5-axis grinding center is ideally suited for grinding complex geometries, especially those used in blades or heat shields for aerospace turbines. The workpieces to be machined can be loaded manually or automatically into the work area in a very ergonomic manner. The compact, space-saving design of the center makes full use of the available production area and enables efficient production processes.

For highly flexible workpiece machining, the integrated tool changer can be loaded with different grinding wheels, and tools for milling and drilling operations as well as measuring probes for quality assurance or checking the position of the workpiece.

Powerful spindle drives allow different grinding processes to be combined, for example, slow-feed grinding with aluminum oxide or grinding with CBN. Full performance and high torque even at low speeds. The robust tool holders allow for wide machining contours and high grinding rates. The grinding process can be carried out with emulsions or oils. High-performance spindles of up to 12,000 rpm provide optimum machining conditions for demanding grinding and milling processes, which can be efficiently performed in the same clamping.

The wheel cleaning function optimizes the grinding process. The grinding wheel remains clean and sharp for a long time during the grinding process, which significantly increases the cutting capacity and reduces wheel wear.

The tabletop dressing machine allows the use of wide diamond wheels with various profiles for different workpieces, significantly reducing set-up times. The new drive technology enables reliable dressing over the entire speed range.

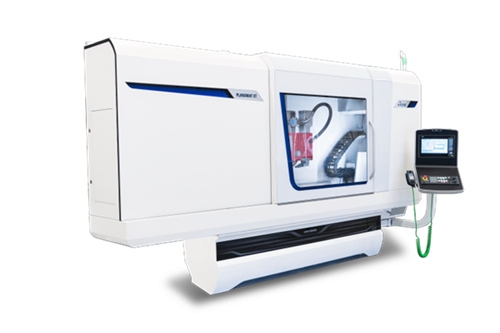

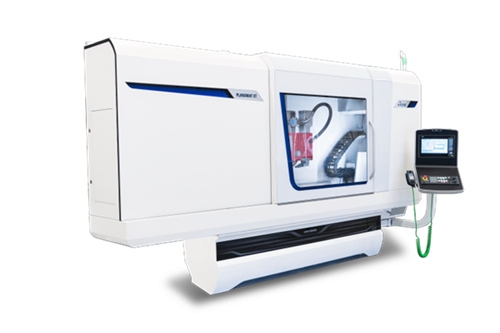

.jpg) BLOHM PLANOMAT XT

The latest generation with outstanding dynamics and improved performance characteristics

BLOHM PLANOMAT XT

The latest generation with outstanding dynamics and improved performance characteristics

Higher shaft speeds, acceleration and system rigidity - the combination of these improvements continue to increase productivity while also improving workpiece quality and achieving higher part quality. The PLANOMAT XT is a robust, high-performance universal machine for surface and profile grinding that builds on the experience and quality of the best-selling PLANOMAT HP. To meet the different demands of daily production and flexible technical applications, BLOHM has developed a series of new machines. The wide range of accessories combined with the modular system of the PLANOMAT XT (sizes from 400x800 to 600x2000 mm) makes this new generation of machines the optimum grinding machines for all customers.

In addition to high-quality machine components such as grinding ball-type linear drives, optimized ductile iron and precision linear guides, this generation is also available with an Industry 4.0-compliant visual display screen for coolant, status and process monitoring.

The PLANOMAT XT combines many technologies: it can be used for oscillating and slow-feed grinding and fast-feed grinding with the optional X-axis linear drive (LDA).

Powerful, dynamic and efficient: the PLANOMAT XT offers the best prerequisites for meeting the highest demands of daily production and the requirements of flexible technical applications.

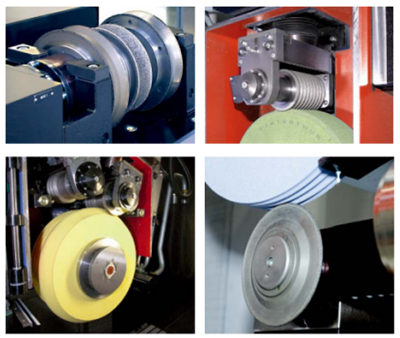

Moresuperhard Excellent Grinding Products for MÄGERLE, BLOHM and JUNG Grinders:

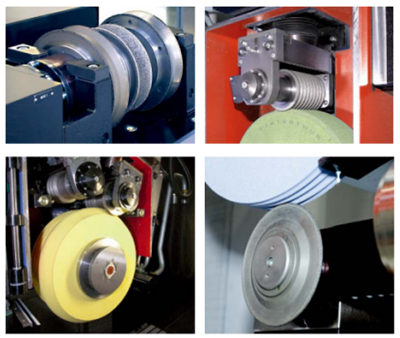

CNC Set Series Grinding Wheels

Moresuperhard

Moresuperhard's CNC grinding wheels have good wear resistance, retention and self sharpening, and can be combined with equipment according to processing requirements:

1. powerful grooved and grooved grinding wheels (1A1, 3A1, 14A1, 1V1, 3V1, 14V1)

2. gear cutting grinding wheels (1V1, 12V9...)

3. angle grinding wheels after edge cleaning and grinding (11V9, 12V9)

4. precision grinding series grinding wheels, etc.

It can be used to process all kinds of solid carbide or high-speed steel milling cutter, drill, reamer and other products on a

5-axis CNC grinder.

.jpg)