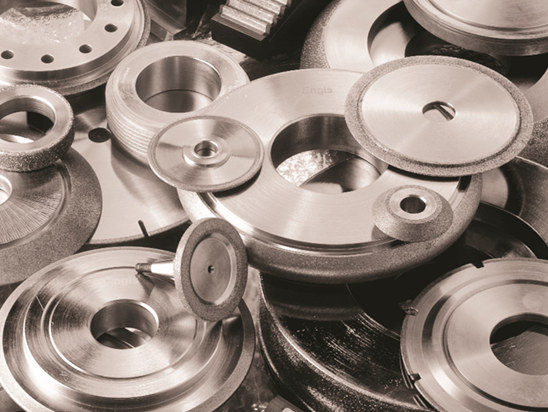

Supplier electroplated diamond wheels for ceramic grinding

Electroplated diamond wheels are precision engineered to meet the high demands of tool and die, ceramic and composite applications.

Diamond electroplated wheels for grinding Technical ceramics, Fiberglass, Plastics, Composite materials, Stone, marble, Glass, Non-ferous metals, Rubber

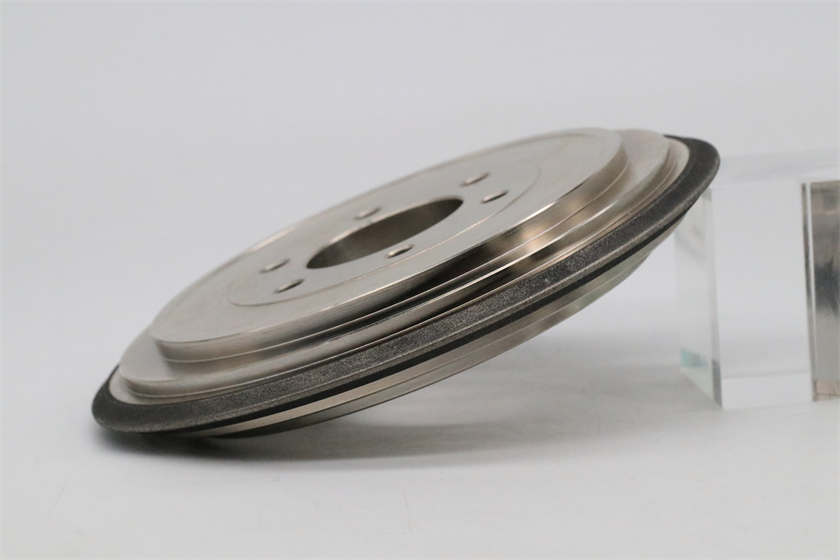

Electroplated Diamond or Cubic Boron Nitride (CBN) wheels have a single layer of abrasive held by a tough, durable nickel alloy. Unlike sintered (metal bond) or resin bond Diamond or CBN products in which the abrasive diamond particles are buried in the bond and held together by a metal or resin binder, electroplated products allow the diamond particles to protrude from the surface for maximum abrasive particle exposure. Experience freer, faster cutting action with minimum heat generation.

Advantages of electroplated diamond wheels

- Ability to cut freely – Cuts cooler – no metallurgical part damage

- No truing or dressing is necessary

- High Precision – Consistent parts batch to batch.

- When the diamond mono- layer is worn out, return the wheel to Engis for re-plating.

- Available in any form, and in a variety of grit sizes