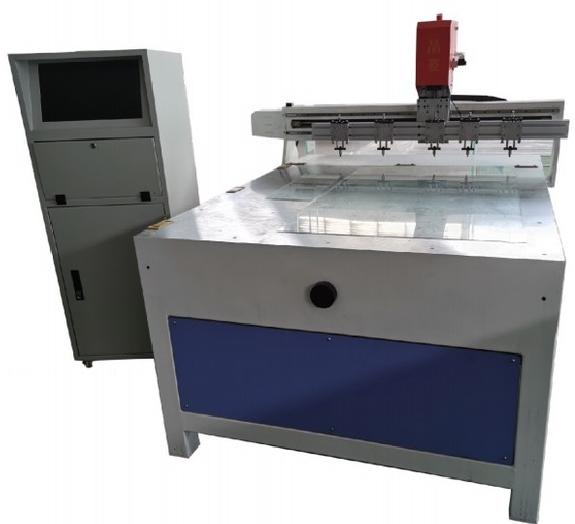

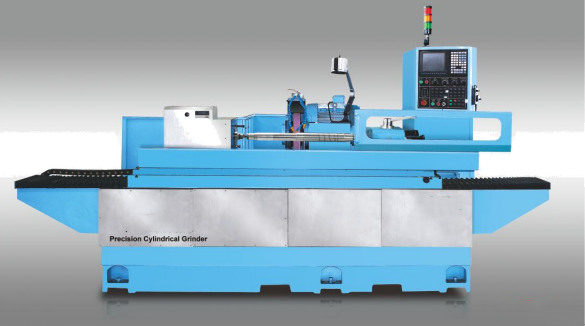

High Precison Servo Surface CNC cylindrical grinder Chinese Manufacturer

With hydrostatic liquid suspension electric spindle, high rigidity, high speed, low vibration, high grinding force.

►Servo Surface CNC cylindrical grinder Models

GP32

J2

►Applications:

– automotive and aerospace industries,

– tool manufacturing

– die makingn

Machine tool processing accuracy (standard test piece):

a. Roundness: ≤0.003

b. Cylindricity: ≤0.008

c. Surface roughness: outer circle: Ra≤0.32μm

d. C-axis angle: ±0.0020

Model overview of Servo Surface CNC cylindrical grinder

1.The MS8320 series follow-up CNC crankshaft grinder has a movable grinding wheel frame structure. The overall reduction of the machine tool contributes to the space saving of the production line. It has automatic feeding of the grinding wheel frame, rough and fine grinding, automatic gear skipping of the workbench, automatic dressing of the grinding wheel and Automatic compensation after trimming and other functions; this machine can grind the outer circle and end face of the workpiece at one time, and continuously grind multiple steps in one clamping. The processing can be programmed and batched, shortening the production cycle, thus enabling users to Obtain good economic benefits.

2:bed frame:

The integral structure of the machine bed fully considers the overall rigidity of the grinder. The castings are made of customized high-grade HT300 produced by Hangzhou Machinery Casting Co., Ltd. and have been subjected to secondary aging treatment. The guide rails and main joint surfaces are manually scraped after guide rail grinding. The wide water tank design ensures Cooling water return flow is smooth.

3: Control system

The CNC system is equipped with Japanese Lenac (special system for crankshaft) with built-in PLC and color LCD display. The operator can set grinding parameters through the display screen through human-machine conversation, edit the grinding process cycle, and realize automatic grinding of the machine tool. Color LCD display in Chinese, built-in machine tool control panel (axis selection switch, inching tool setting, quick feed, spindle speed setting, etc.), with X and Z axis linkage to realize linear feed and linear and arc interpolation of the two axes; sharing an electronic handwheel operation (with ×1, ×10, ×100 magnification switching); it can realize screw pitch error compensation, backlash compensation, grinding wheel dressing compensation, self-diagnosis and other functions. It has a communication interface with PC (RS232 interface) and is equipped with a memory card.

4:Transmission system

The grinding wheel frame feeding mechanism uses a cross slide to achieve X-axis and Z-axis linkage. The X-axis and Z-axis moving guide rails are equipped with Taiwan Shangyin heavy-duty ball guide rails with large bearing capacity and high feed sensitivity, ensuring the feed accuracy of the grinding wheel frame. The X-axis feed adopts Japanese Sodick series linear motor. Combined with high-precision Spanish Fagor grating ruler, closed-loop control is implemented, and the linear motor is equipped with a cooling device.

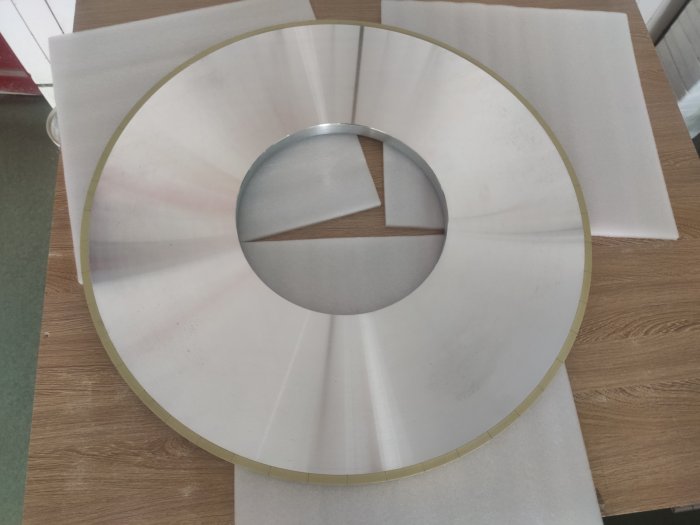

5: Grinding wheel spindle

The grinding wheel frame motor adopts a new generation disc type direct drive motor, which is directly connected to the dynamic and static pressure spindle, eliminating vibration and noise caused by the original belt drive, high torque transmission in the entire range, faster acceleration and deceleration characteristics and servo characteristics, good servo response and rigidity High and low noise. The spindle adopts an ultra-precision dynamic pressure spindle, which has sufficient static pressure bearing capacity when stationary, and can generate strong dynamic pressure power and ultra-high precision when rotating. The spindle is always suspended on the oil film, with no metal contact, and can maintain ultra-high precision for a long time. , its huge dynamic rigidity and load-bearing capacity are many times stronger than that of a ball bearing spindle, which improves its cutting accuracy and ensures the best combination of stiffness and accuracy of the machine tool. It is equipped with a domestic CBN grinding wheel and grinds at a constant linear speed of 80m/s.

6: Head frame

The main spindle of the machine tool headstock adopts a DD motor directly connected to the spindle structure and is equipped with a cooling function. The top number is Mohs 4#. It is controlled by the CNC system to link the rotation of the headstock spindle with the feed motion of the grinding wheel frame to achieve non-circular grinding profiling. sports.

7: Tailstock

Highly rigid tailstock, the sleeve adopts a dense ball bearing structure, with zero radial movement of the sleeve; ensuring zero radial clearance fit between the sleeve and the steel sleeve. The power source of the tailstock is hydraulic single-action, and the top number is Mohs 4#. When grinding workpieces of different lengths, you can loosen the hexagonal bolts and push the tailstock to move the tailstock longitudinally along the workbench to the desired position.

8: Measurement system

The machine tool is equipped with end face and corner measuring instruments to detect end face errors and corner positions.

9: Grinding wheel balance and backlash elimination system

Machine tools can be equipped with online dynamic balancing, backlash elimination and anti-collision devices. It can monitor and analyze the high-frequency signals generated by the grinding process, and can automatically monitor the quality of the grinding product and the quality of the grinding wheel dressing.

10:cutting cooling system

Equipped with a large-flow cooling pump and a 200L large-capacity paper filter water tank to fully ensure the cleanliness of the cooling water with a filtration accuracy of 30um, so that the grinding workpiece can achieve a very high finish; equipped with a multi-stage centrifugal pump, the water pump flow rate is 6m³/h, and the lift is 18m, power 0.55Kw, equipped with handheld cleaning water gun.

11.Hydraulic (separated from the bed), lubrication, pneumatic system