Double disc grinding wheels supplier

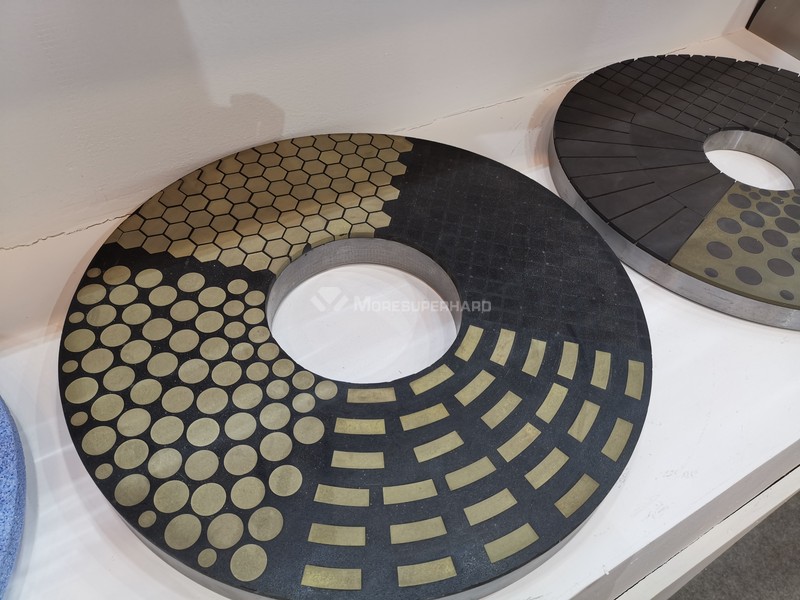

Double-sided grinding wheel is to use two oppositely installed grinding wheels to simultaneously grind the two end faces of the workpiece. There are mainly ceramic bond and resin bond super-hard double-side grinding wheels

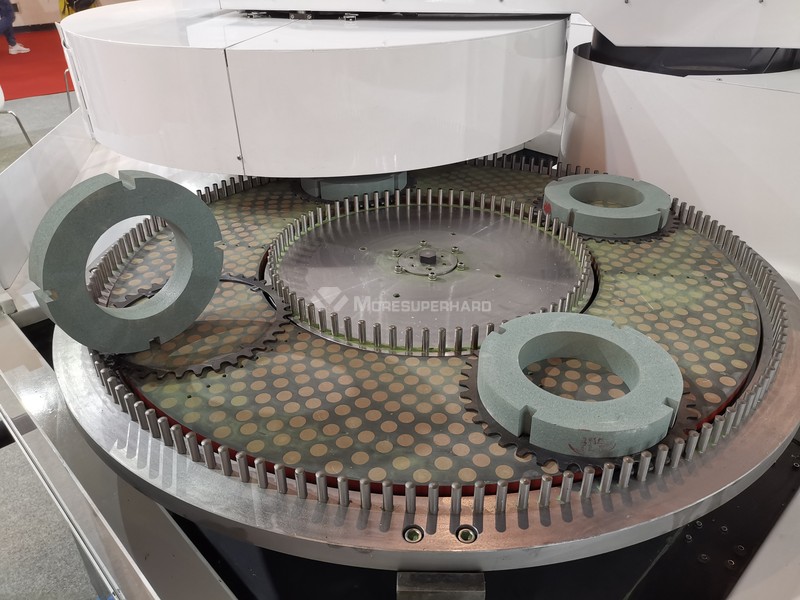

More Superhard exhibited double-faced grinding wheels, ceramic outer grinding wheels, tool grinding wheels, and ceramic inner grinding wheels. Double-end grinding is to use two oppositely installed grinding wheels to simultaneously grind the two end faces of the workpiece.

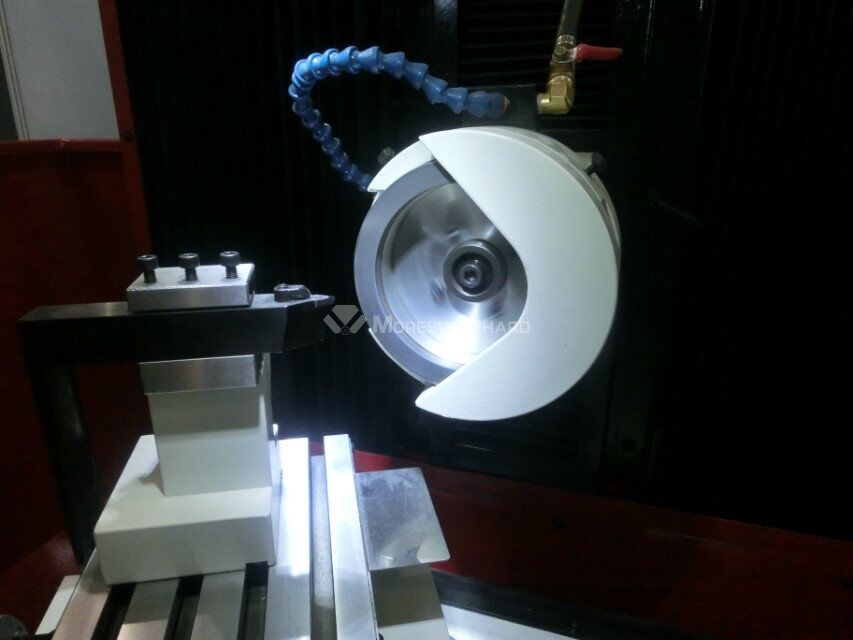

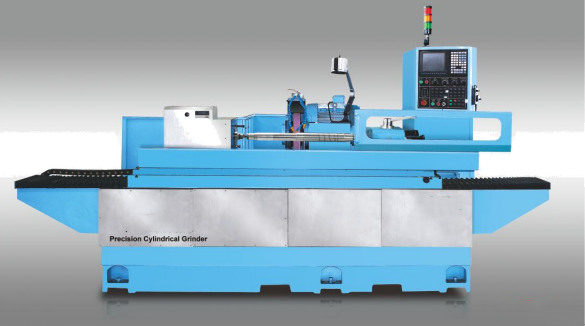

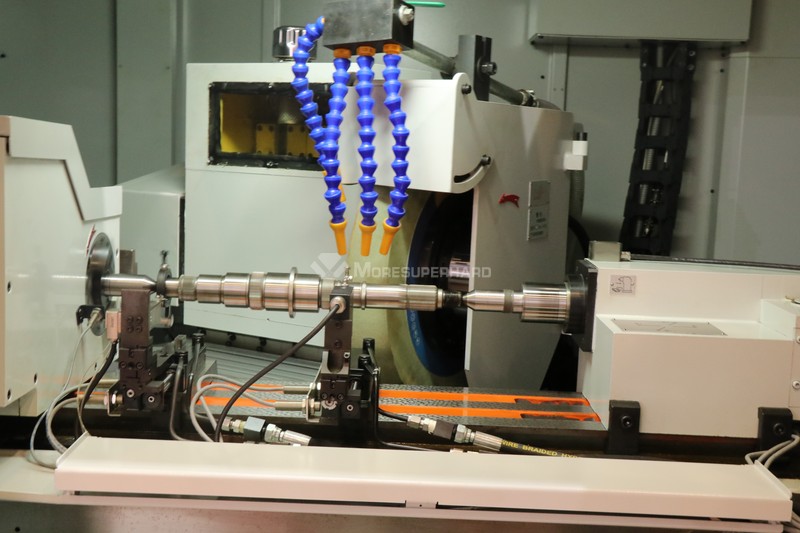

There are mainly ceramic bond and resin bond super-hard double-end grinding grinding wheels. Ceramic cylindrical grinding wheels are mainly used for engine crankshaft connecting rods and Efficient and powerful grinding of shaft diameter surface, camshaft peach-shaped surface and spindle diameter surface, precision grinding of outer circle, end surface and spline of automobile gearbox shaft and motor shaft. It has the characteristics of high processing efficiency, high precision, no burns and surface annealing, long service life and easy dressing; internal grinding and universal joint grinding wheels are used in compressor piston internal grinding, cylinder internal grinding, and cylinder internal grinding. The internal grinding of the cover and the frame has a large material removal rate and good heat dissipation performance; tool grinding wheels are used for groove grinding, relief grinding, peripheral grinding, end surface grinding, tooth fine grinding, and coarse grinding of CNC tools. Processing, semi-finishing, finishing, polishing and other processes, the sharpening of PCD and PCB cutting tools, blades and other cutting tools, as well as the peripheral grinding of indexable inserts, with high precision, high speed, high grinding efficiency, and shape Good retention, sharp grinding, high durability, easy dressing, good profile accuracy retention, and good blade edge quality.