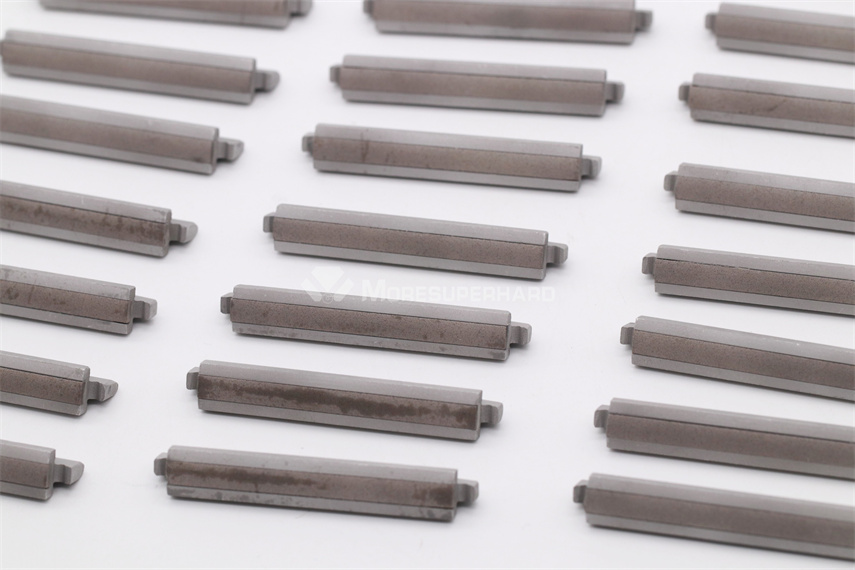

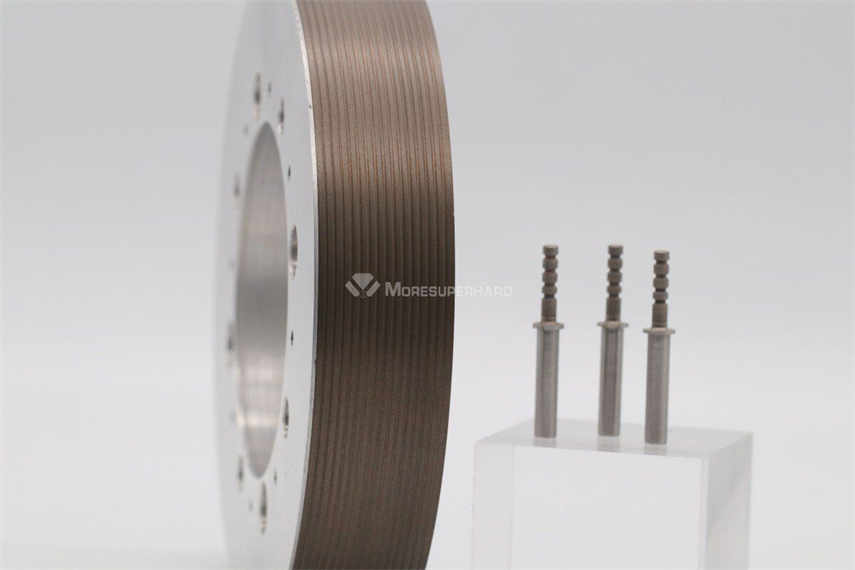

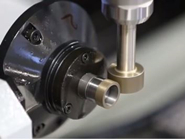

The general way of domestic rail grinding is that the special grinding train is equipped with 48-96 resin grinding wheels, each side of the rail is allocated 48, arranged in the rail profile section -70 degrees until +20 degrees at different positions.High efficiency long life vitrified & resin hybrid CBN rail grinding wheel. The new superhard material cubic boron nitride (CBN) is used to replace the traditional zirconium corundum material as the main abrasive of the grinding wheel.

Advantages of vitrified resin hybrid CBN grinding wheel for rail track grinding are mainly reflected in the following points:

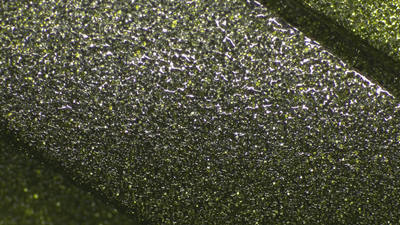

(1) Hardness of CBN is equal to 2 times of the hardness of corundum, and the grinding efficiency is more than 3-4 times of the ordinary grinding wheel, which can greatly improve the working speed of the grinding .

(2) The service life of CBN grinding wheel can reach 20-40 times of ordinary grinding wheel, and the change frequency is low in the grinding process. The grinding wheel has little wear and low dust concentration per unit kilometer, which can solve the environmental problem of dust exceeding standard when the traditional grinding wheel is working.

(3) The thermal conductivity of CBN grinding wheel is 45 times that of corundum, the heat generated in the grinding process is less, and the resin will not crack to produce harmful gas. At the same time, the grinding rail is not easy to produce grinding burn cracks, which can extend the service life of the rail by 20-30%.