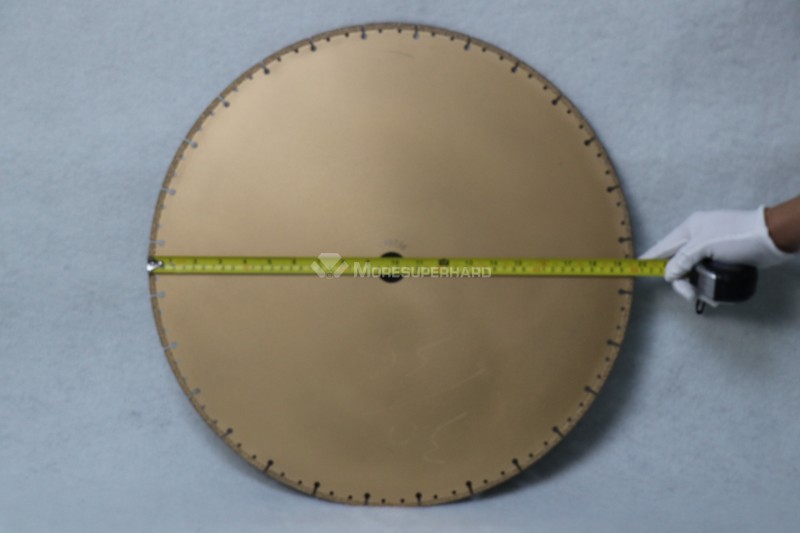

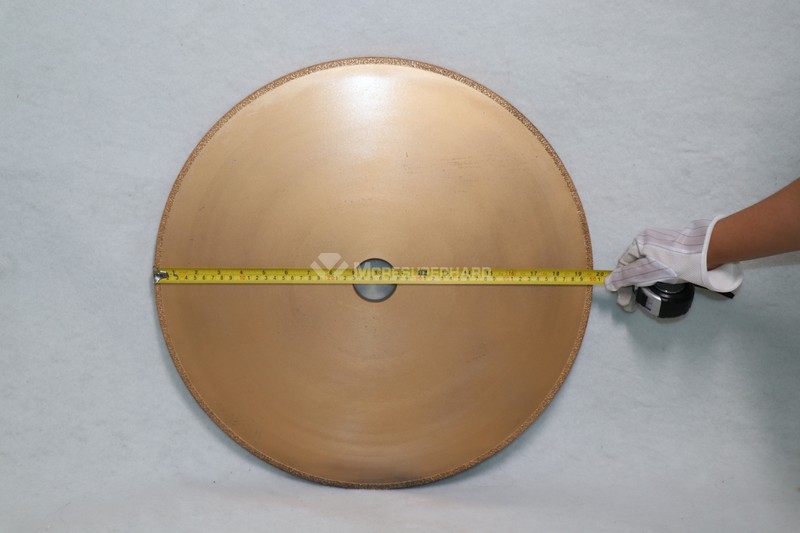

Vacuum brazed diamond disc for foundry, metal processing

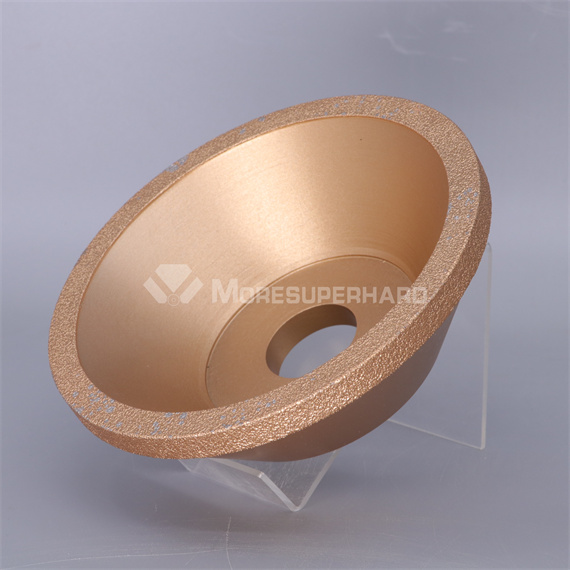

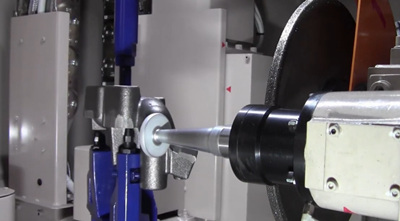

Vacuum brazed diamond disc are used on hand held grinder and used for grinding, weld cleanup, stock removal and beveling in a wide variety of industry include Foundry, Metal Processing (Weld Removal And Pipe Beveling Of All Ferrous And Non Ferrous Metals) , Auto Parts, Ship Building , Stone , Ceramic, Plastic Processing ,And Composite Materials ,Etc

Vacuum brazed diamond disc have continuous type and segment type. They are used for cutting Marble, cast iron, Ceramics tiles, hard composite materials such as concrete with rebar, Metal processing, Fiber Glass and PVC pipe, etc

Advantages Of Vacuum brazed diamond disc

* Single Layer Of Fully Exposed Diamond Fused With Nickel At High Temperatures And Sharp Cutting

* Small cutting gap and less chipping

* Up To 40 Times Longer Life Time Than Resin Grinding Disc. the efficiency is improved by 100% for cutting FRP slab

* Higher Quality Process Than Sintered or Laser Welded Diamond Wheel. The efficiency is improved by 35% for cutting marble slab

* No Pollution, Low Noise ,Never Need Dressing