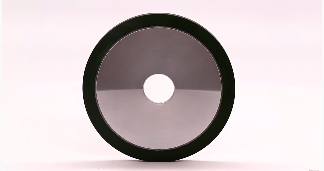

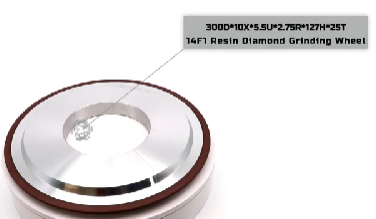

Resin Bond Diamond Grinding Wheel for Carbide

Resin Bond Diamond Grinding Wheel for Carbide

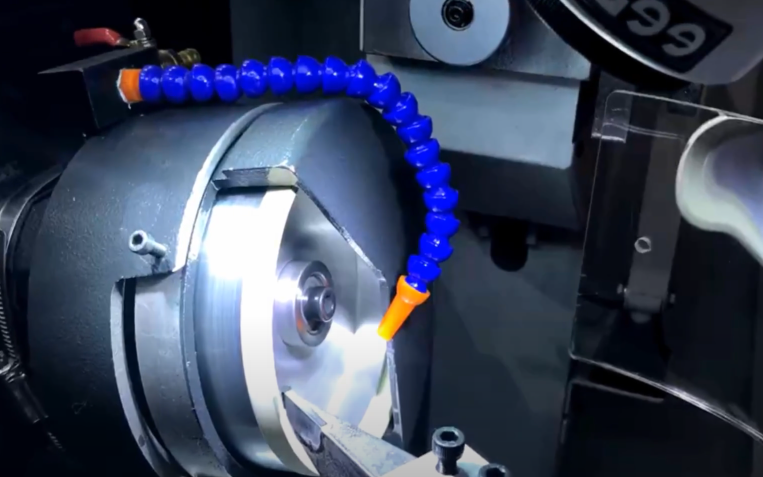

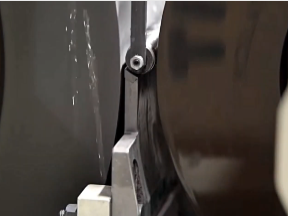

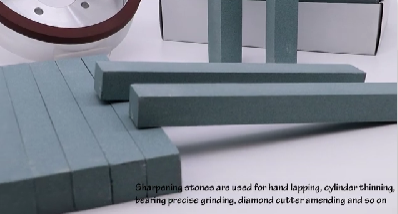

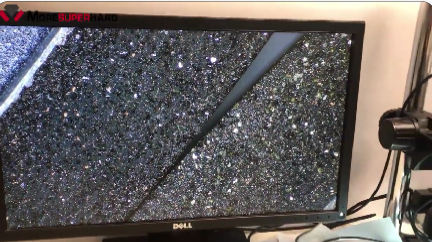

Workpiece Materials: grinding tungsten carbide cutting tools, ceramic , magnetic materials, silicon , glass , quartz and thermal spraying alloy ,etc Applicable Industry: CNC Tool Grinding, Woodworking Tool Grinding, Thermal Spraying Coated, Silicon Wafer Grinding, etc

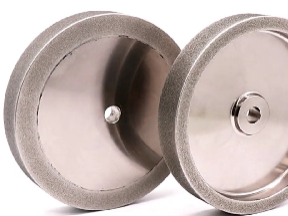

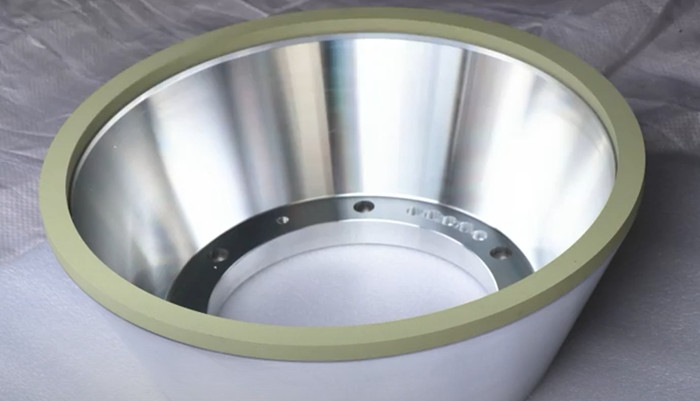

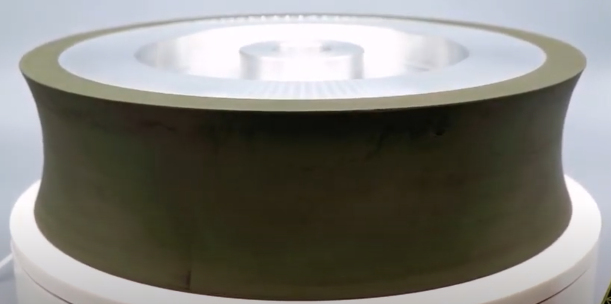

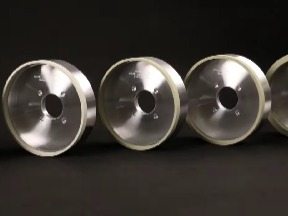

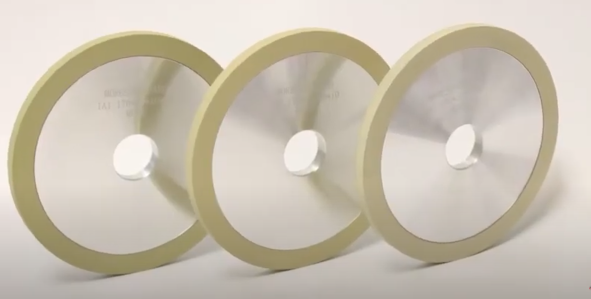

Type: 1A1R, 1A1, 3A1, 1V1, 4A2, 4BT9, 6A2, 11V9, 12A2, 14F, etc

Advantages of resin diamond grinding wheel:

* High cutting efficiency, good self-sharpening, less blocking, reducing the grinding burn occurs when the phenomenon of work

* Good flexibility will help to improve the surface roughness, mainly used for rough grinding, semi-fine grinding, polishing and other processes

* Compared to conventional silicon carbide , resin diamond wheel has good material removal rates, longer wheel life and lower grinding costs

* Resin bond diamond wheels generally remove material up to 10 times faster than metal bond wheels