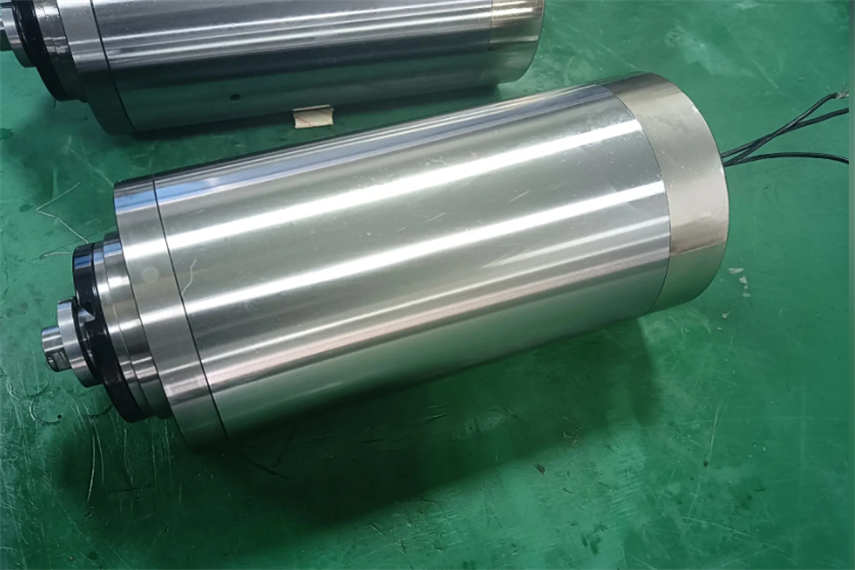

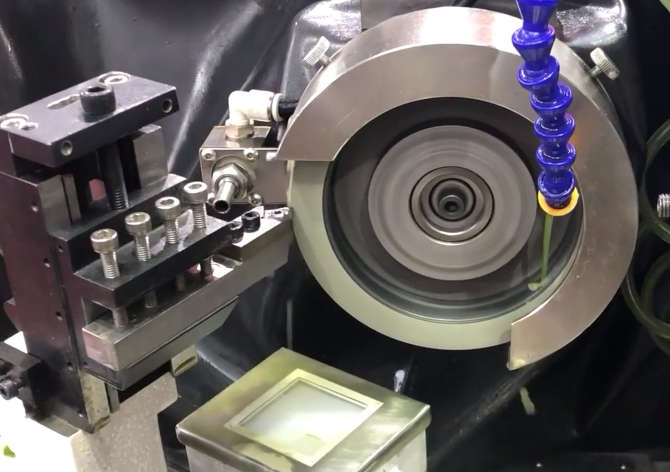

5 axis cnc grinding machine with diamond wheel

5 axis cnc diamond grinding wheels are used for grinding carbide and HSS. (such as drill, end mill, reamer)

A complete solution for CNC tools manufacturing: fluting, gashing and Clear edge, relief angle grinding, OD grinding

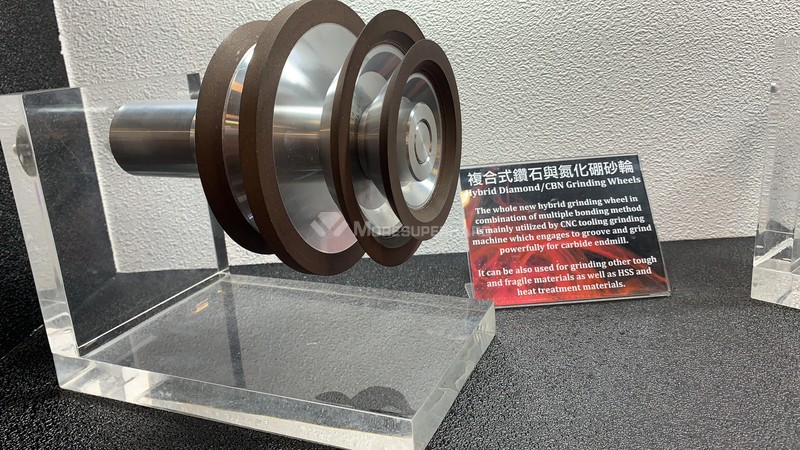

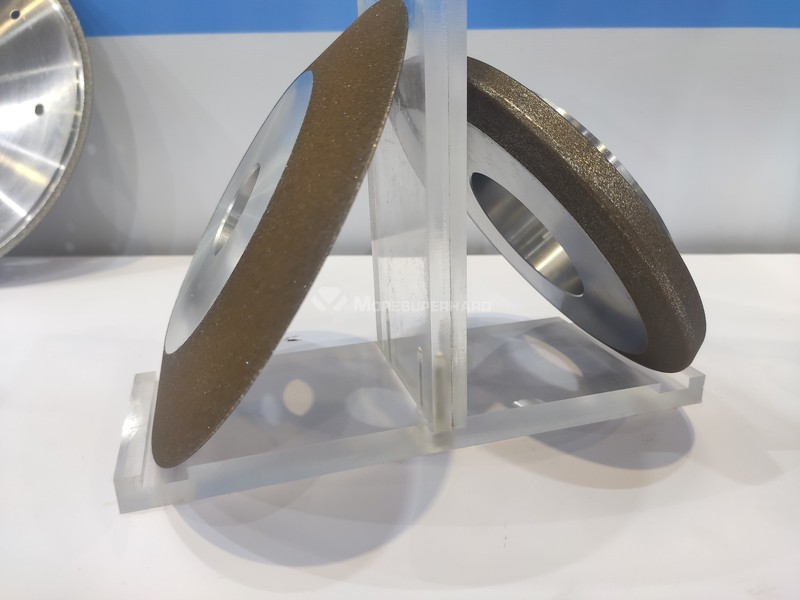

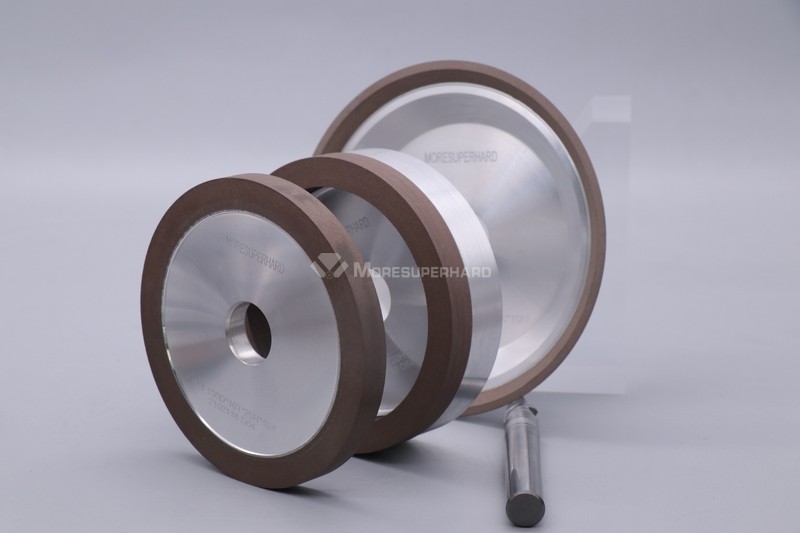

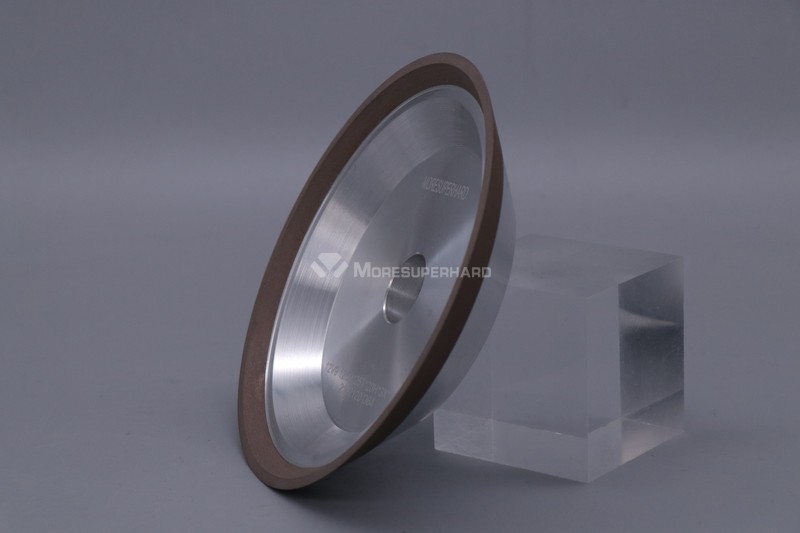

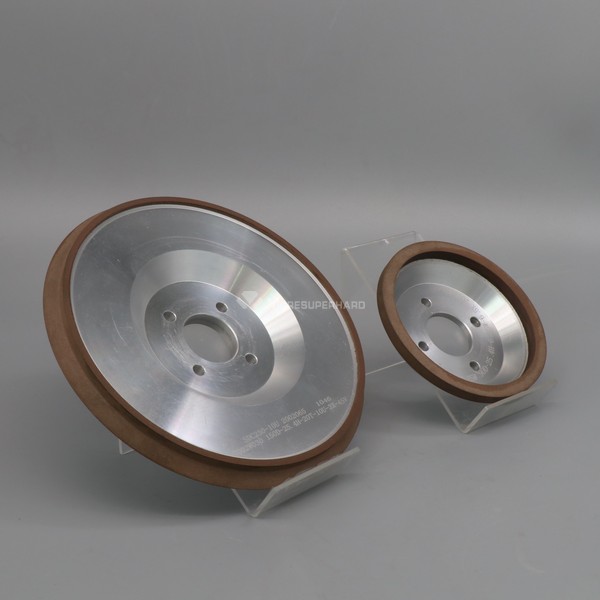

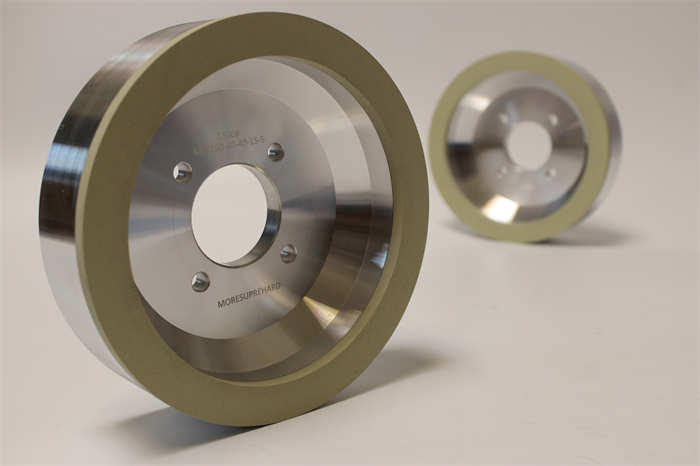

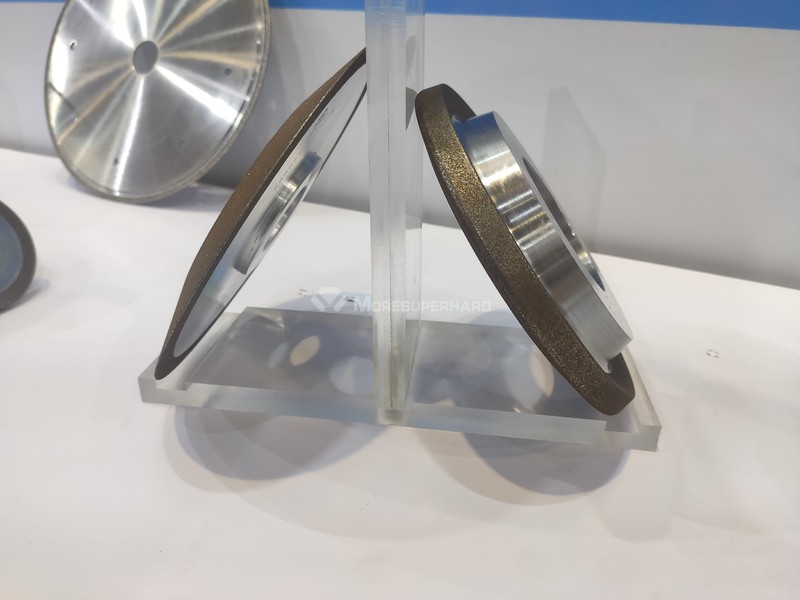

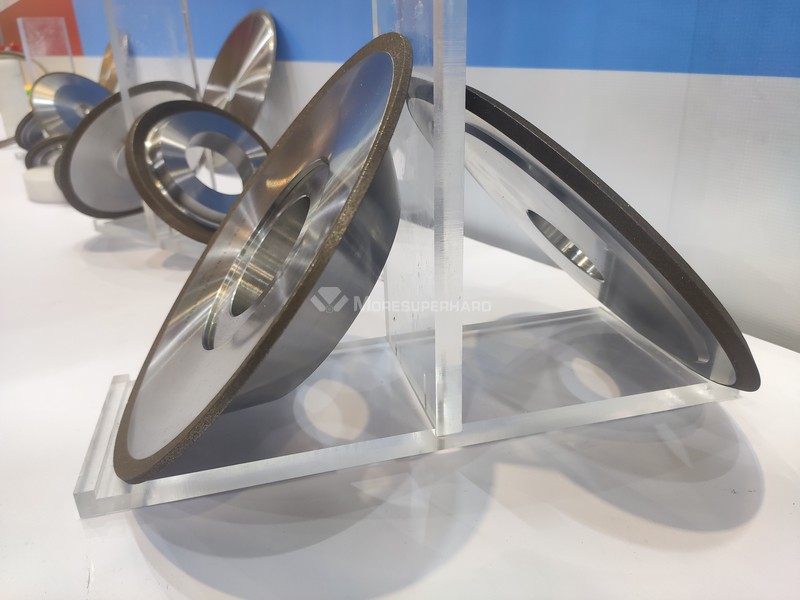

Model of cnc wheels: 1A1, 1V1, 11V9, 12V9, 14A1, 12V5, etc

5 axis cnc grinding machine with diamond wheel, Resin Grinding Wheel CNC Tool

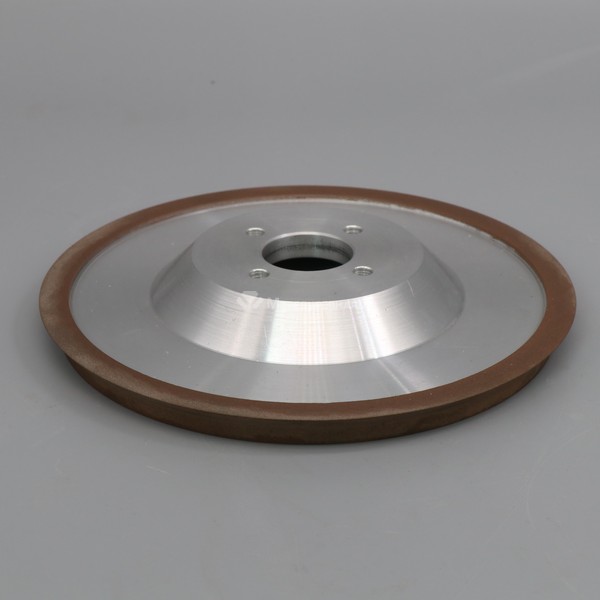

Diamond resin grinding wheel has high hardness, high strength and strong grinding ability.

Mainly used for grinding high and hard alloys, non-metallic materials, cutting hard and brittle hard alloys, non-metallic minerals, etc. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials, wear-resistant cast iron, stone, etc.

Features of cnc diamond grinding wheel: The diamond resin grinding wheel has a good polishing effect. The grinding wheel is sharp and not easy to be blocked during grinding.

The specific features are as follows: Resin diamond grinding wheel

- The grinding efficiency is high, and the grinding wheel consumption is relatively slow;

- Good self-sharpening, low heat generation during grinding, not easy to block, reducing the phenomenon of work burns during grinding;

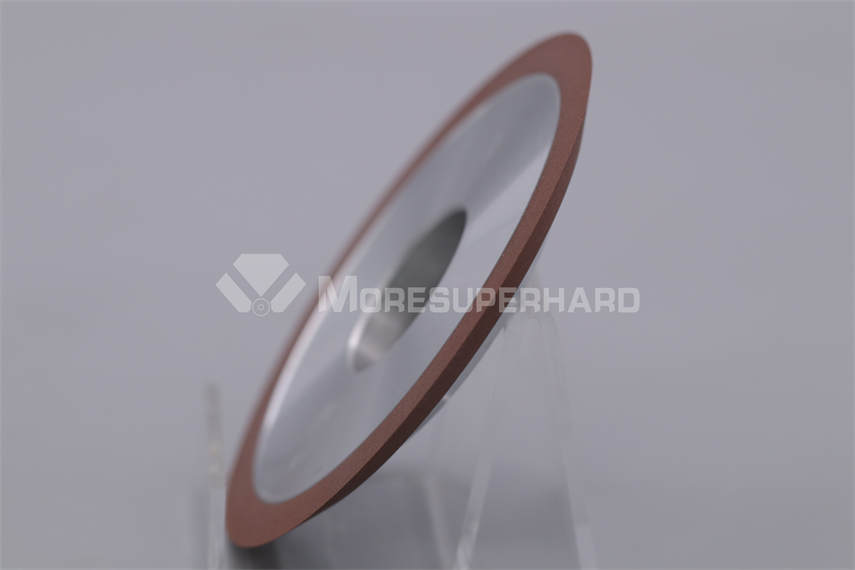

- The grinding wheel has certain elasticity, which is beneficial to improve the surface roughness of the workpiece, and is mainly used for fine grinding, semi-finishing grinding, knife grinding, polishing and other processes;

- The diamond resin grinding wheel is solidified at low temperature, the production cycle is short, and the equipment and supply process are relatively simple; because the resin has fluidity, it is easy to form a grinding wheel with a complex surface.

Classification: Diamond resin grinding wheel (resin knife grinding wheel) can be selected according to the product model (parallel grinding wheel, parallel arc grinding wheel, double-sided concave grinding wheel, double bevel grinding wheel, bowl grinding wheel), etc.

Their uses: Parallel grinding wheels: mainly used for cylindrical grinding and cutting edge processing of cemented carbide, parallel arc grinding wheels: mainly used for forming grinding of cemented carbide and forming grinding of arc surfaces, double-sided concave grinding wheels : Mainly used for grinding measuring tools and coreless grinding wheels,

Double bevel grinding wheel: mainly used for forming grinding of carbide gear hobs and thread cutters,

Bowl-shaped grinding wheel: mainly used for sharpening hard alloy tools and high-speed steel tools, and also for milling.