Last time we talked about the influence of stress on the shape and position tolerance and accuracy of grinding wheel matrix. Today, we take the

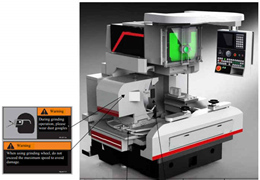

peripheral grinding wheel as an example to talk about how to control the deformation of the grinding wheel matrix during the finishing process.

(1).png)

Industry insiders understand that most peripheral grinding wheels are large diameter, large bore, narrow wall width, and poor pressure resistance, and the chuck loading is prone to cause large errors in its roundness.

.png)

When the substrate is drilled in the machining center, its flatness and parallelism are deformed by pressure; the peripheral grinding dynamic balance cannot be de-weighted, thus requiring higher machining accuracy to eliminate the unbalanced weight and make it meet the requirements of the balance standard without de-weighting. This requires the reducer sleeve for finishing to fit just right, too loose concentricity is not good, too tight loading reducer sleeve deformation by force will affect the parallelism.

.jpg)

.jpg)

There are also large diameter 300-350-400 abrasive layer after the whole ring sintering, abrasive ring is actually an oval, in order to reduce the wheel dynamic balance bias, you can use the fixture to fix the abrasive layer, grinding the inner hole of the abrasive layer on the grinding machine to round with the substrate, and then grinding the abrasive layer plane, and finally bonding, can further reduce the roundness, parallelism, flatness error, which is also a necessary condition for the peripheral grinding dynamic balance to meet the standard. Finally, the loading method of finishing is also crucial. Our machining master has nearly 20 years of processing experience and has invented a set of special loading method, which can effectively weaken the loading stress.

Small peripheral grinding substrate, involving material expansion coefficient, compressive and tensile properties, internal stress deformation generation and natural aging, to conduct a long time experiment on the above issues, and gradually improve the processing process to achieve the perfect product.

Moresuperhard produces various types of grinding wheels, adaptable to the peripheral grinding machines produced by WENDT (Germany), WAIDA (Japan),

AGATHON (Switzerland), EWAG (Switzerland),

COBORN (UK) and related domestic manufacturers.

If your grinding wheel has a large error of flatness and parallelism between the bottom and abrasive layer after loading, and a long dressing time, it is possible that the stress changes during the processing of the substrate have not been dealt with. If you have other problems that you do not understand, welcome to contact the technical engineers of

Moresuperhard!

---EDITOR: Yun Li;Jackie Wang

---POST: Jackie Wang

(1).png)

.png)

.jpg)

.jpg)