Necessary mechanical conditions for diamond roller dressing

1. The diamond roller spindle should have sufficient rigidity and rotation accuracy.

2. The dressing must use the same coolant and cooling capacity and pressure as grinding.

3. The diamond roller and the grinding wheel should have a certain relative speed.

The dressing devices used on grinding machines generally have the following three methods

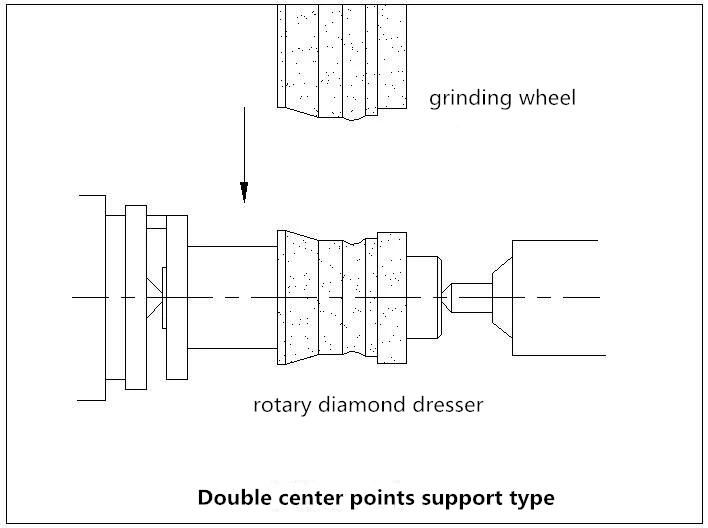

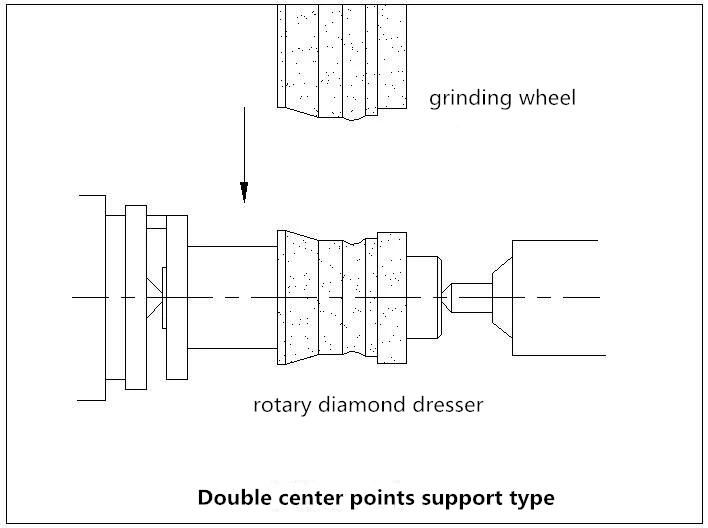

a) Double center points support type

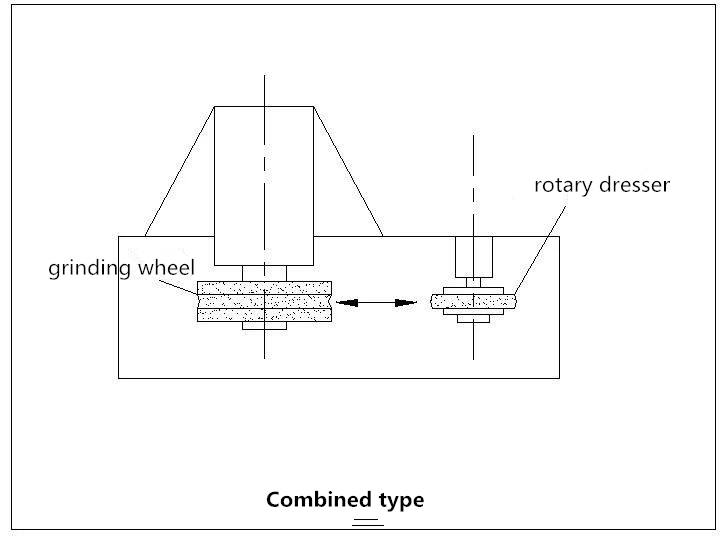

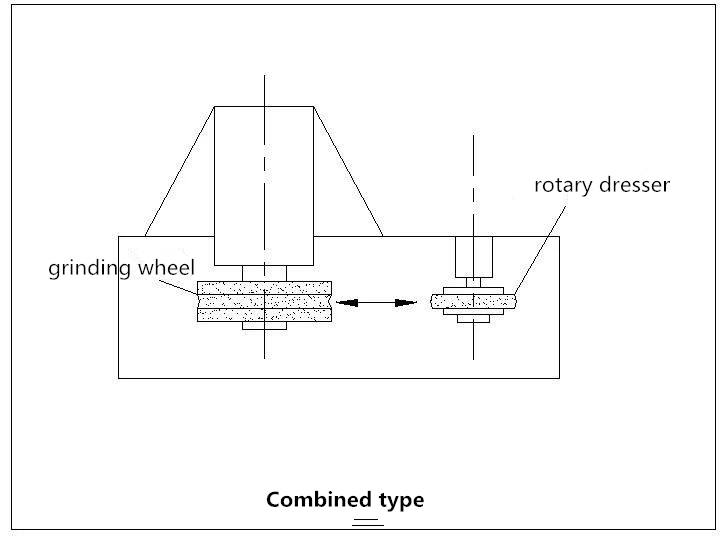

b) Combined type

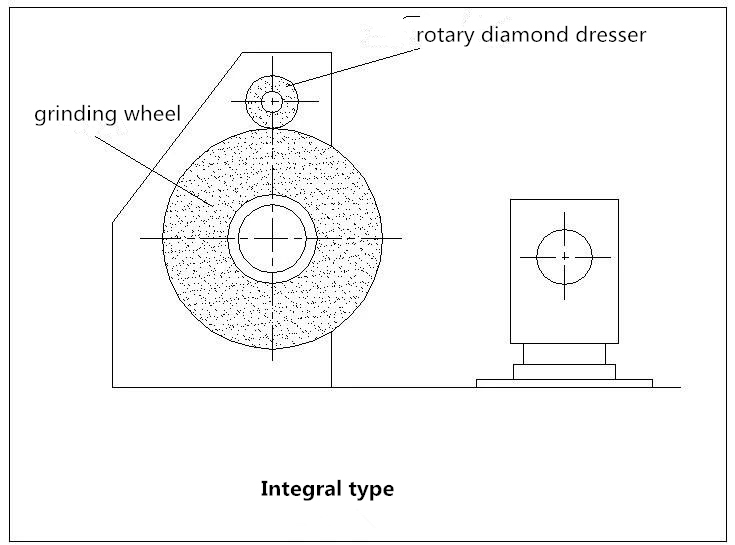

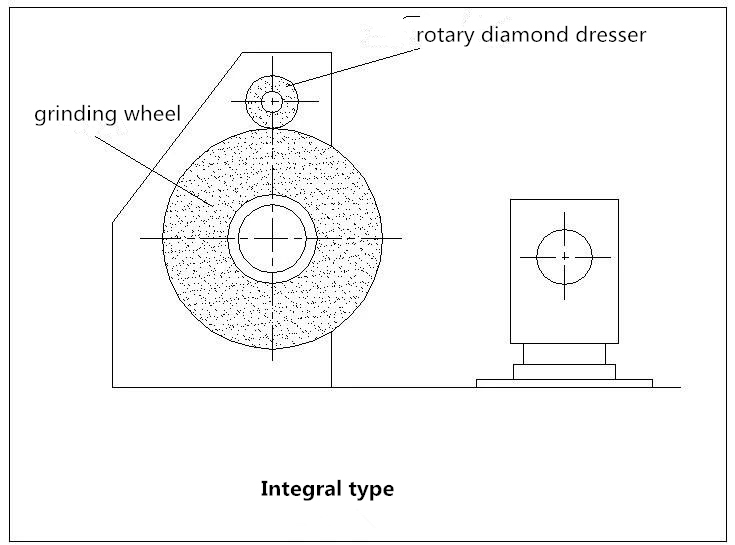

c) Integral type

The characteristics of diamond wheel dressing grinding wheel

The characteristics of diamond wheel dressing grinding wheel

1. High dressing efficiency.

2. High service life (dressing times can reach tens of thousands to hundreds of thousands of times).

3. High-precision diamond rollers can be manufactured from high-precision molds, and high-precision grinding wheel working surfaces that cannot be obtained by other methods can be trimmed.

4. The manufacturing process of diamond rollers is complicated, the cost is high, and the service life of superhard grinding wheels is much lower than that of ordinary abrasive wheels. In order to further improve the life of the diamond roller, the advantages of PCD isotropic and high wear resistance can be used to strengthen the traditional diamond grinding wheel, which is mainly used in the mass production of ceramic bond grinding wheels in the A zone.