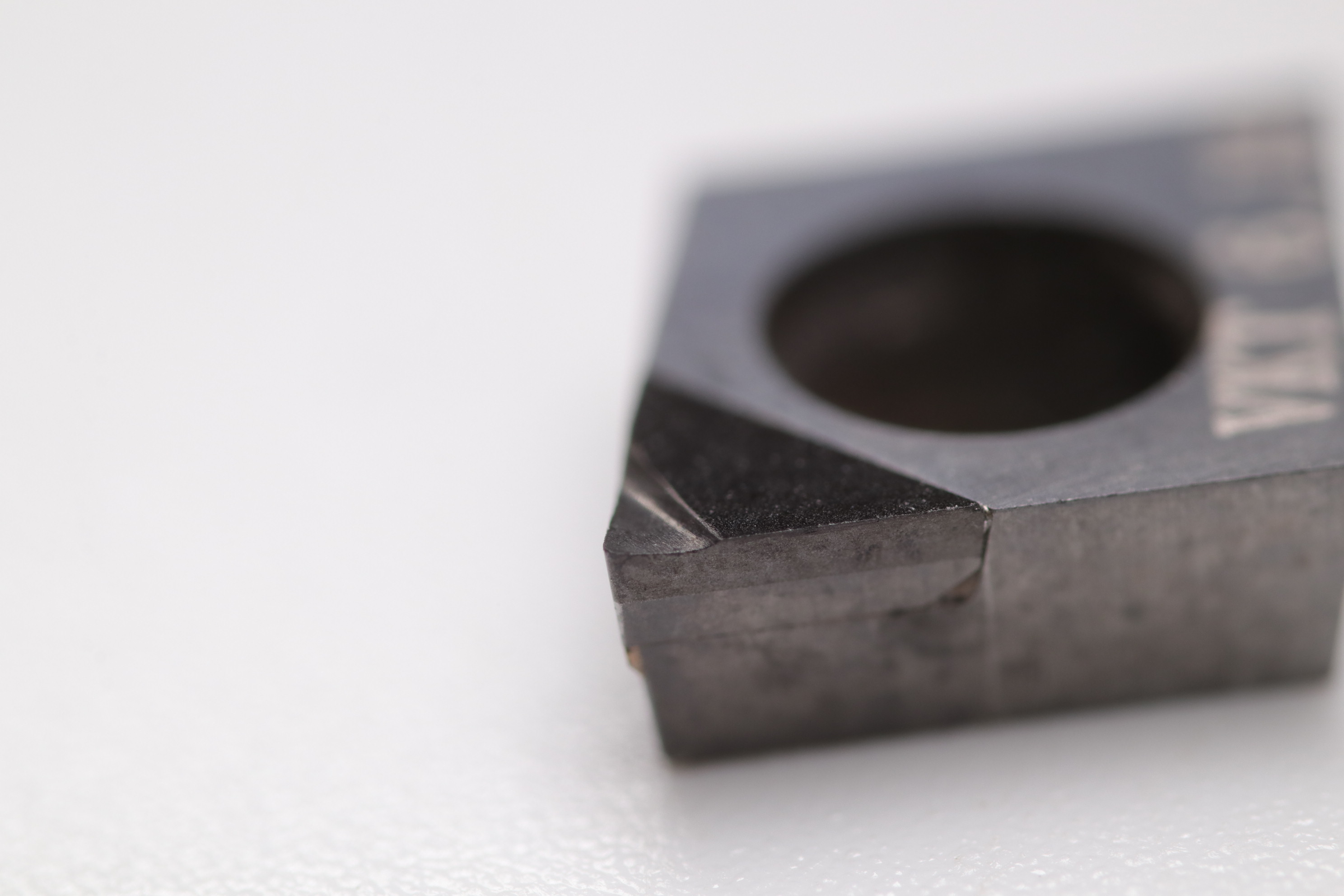

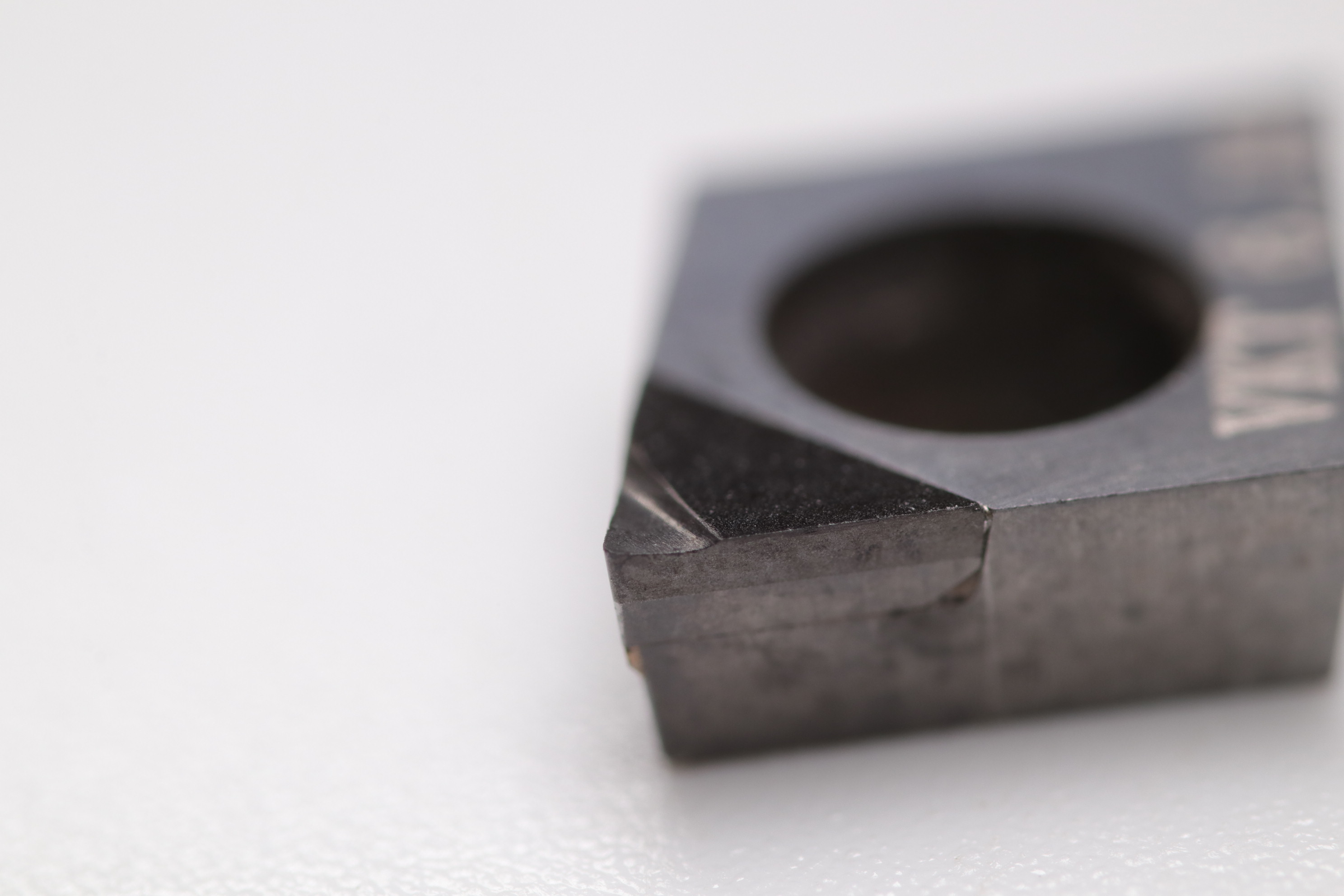

What is chip breaking and why we need chip breaker groove?

Chip breaking is a prominent problem in turning plastic metals.If the chips are continuous and wrapped around the turning tool or the work piece in a ribbon shape, it will not only affect the normal turning, but also scratch the machined surface, and even cause an accident.The purpose of grinding the chip breaker on the cutter face is to cause the chip to generate internal stress and force it to deform and break when the chip passes through the chip breaker.

.jpg)

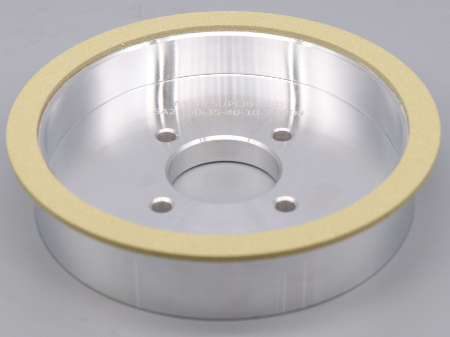

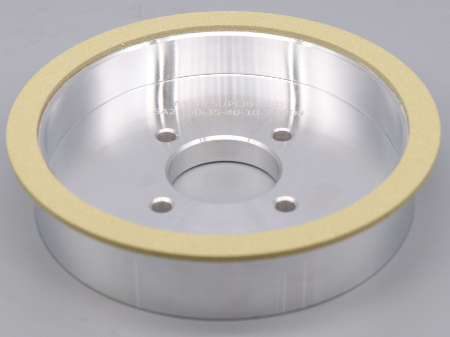

Therefore, we use vitrified diamond grinding wheels to machine PCD tool chip breakers. In order to ensure the grinding accuracy, we divide the grinding into two processes: rough grinding and fine grinding.

When rough grinding, you need to pay attention to the following points:

When rough grinding, you need to pay attention to the following points:

- The starting position of grinding should keep a distance from the tool tip and main cutting edge.

Usually, the distance between the starting position and the tool nose can be made equal to about half the length of the chip breaker; The distance from the main cutting edge is approximately half the width of the chip breaker.

- Make sure the rake value of the turning tool.

The turning tool should be turned at an angle so that the bottom surface of the shank of the turning tool and the side angle of the grinding wheel form an angle roughly equal to the value of the rake angle, and pay attention to the position on the chip breaker. For the parallel chip breaker, it should be parallel to the main cutting edge. When grinding, the main cutting edge should be parallel to the side of the grinding wheel; For the external inclined and internal inclined chip breakers, it is required to form a certain angle with the main cutting edge. During grinding, the main cutting edge should also form a corresponding angle with the side of the grinding wheel.

- Do not use too much force when sharpening.

The turning tool should move up and down slowly along the direction of the tool shank, and the tool tip should always be in front of the vertical line from the center of the grinding wheel to the main cutting edge, otherwise the front port of the chip breaker will easily break. The chip breaker cannot be ground on the main cutting edge, and the size and shape of the main cutting edge cannot be changed at will. When the chip breaker is roughly ground and formed, there should be a distance similar to the value of the cutting edge between it and the main cutting edge, and the grinding should be kept. The edge thickness of the negative chamfer.

- Repeatedly check the shape, position and rake angle of the ground chip breaker.

When the shape of the chip breaker is basically ground and ready to finish rough grinding, the up and down movement of the turning tool should be slowed down, and the turning tool should be withdrawn when the grinding wheel is at the rear end of the chip breaker.

When the chip breaker has been roughly grinding, it can be finely grinding.

During

fine grinding, in addition to the grinding position of the turning tool should be the same as the final position of rough grinding, special attention should be paid to the correct dressing of the grinding wheel, that is, the grinding part on the grinding wheel should be dressed to meet the requirements of the chip breaker. Shape, the turning tool should move up and down more slowly, and the force should be even and slight. When the size and position of the chip breaker meet the requirements and the surface roughness is good, the fine grinding can be finished.

---EDITOR: Cindy Chen,Jackie Wang

---POST: Jackie Wang

.jpg)